Date: 2025-10-22

Let me share something I've learned through years of working with automotive manufacturers: the most innovative wiring solutions often come from recognizing patterns in failure. I recall sitting in a design review at a major automaker, looking at vibration-induced failures in traditional wiring harnesses. The solution we developed with flexible PCBs didn't just fix the problem - it revealed how much better automotive electronics could be.

Today's vehicles are essentially data centers on wheels. I've counted over 50 electronic control units in some luxury vehicles, all needing to communicate reliably while surviving conditions that would destroy most consumer electronics.

The traditional approach of using rigid PCBs connected by wire harnesses creates inherent vulnerabilities. I've seen vibration analysis data showing that connector failures account for nearly 40% of automotive electrical issues. Another 30% come from wire fatigue in high-movement areas like door panels and engine compartments.

The Packaging Revolution

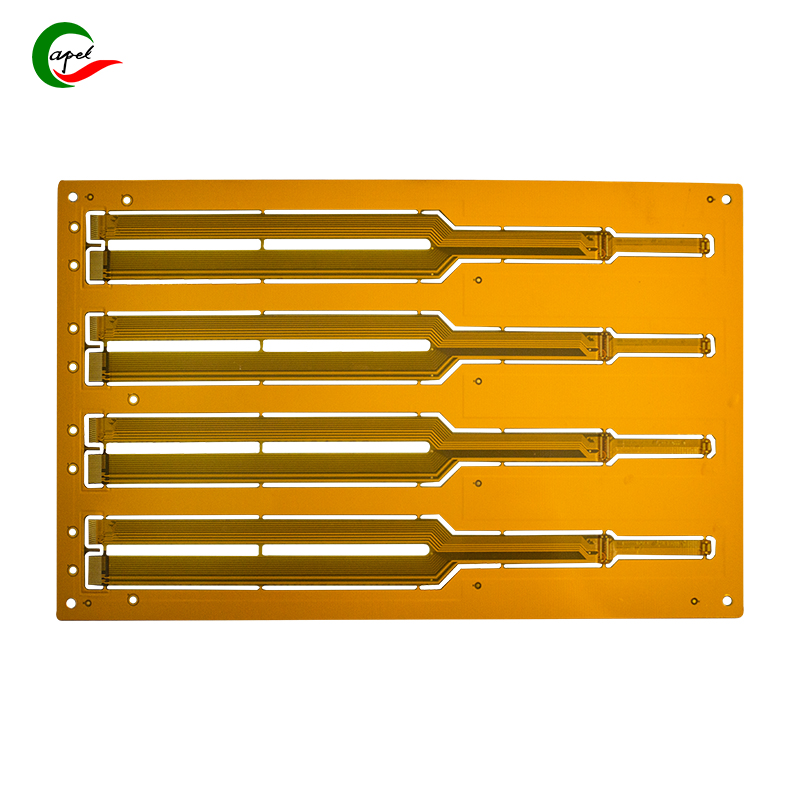

When we first proposed using flexible PCBs for door modules, the manufacturing team was skeptical. Then they saw the numbers: a single flexible circuit could replace an entire harness weighing 450 grams while saving 60% of the space. The real breakthrough came when we demonstrated that the same flexible circuit could integrate power distribution, sensor connections, and data communication in one robust package.

Surviving the Automotive Environment

Our testing revealed something remarkable. Properly designed flexible PCBs withstood vibration profiles that caused conventional wiring to fail within weeks. The secret wasn't just the materials - it was designing for the specific vibration modes of each vehicle location.

For example, in door applications, we found that frequencies between 80-200Hz caused the most damage. By tuning the flexible PCB's mechanical properties and using strategic stiffeners, we achieved reliability that exceeded the vehicle's lifespan.

Material Selection Lessons

Through extensive testing, we've developed material guidelines that work:

For high-temperature areas near engines: Polyimide with 260°C+ thermal stability

For dynamic flexing applications: Rolled copper with 25μm thickness

For chemical exposure zones: Specialized conformal coatings that resist oils and coolants

The Rigid-Flex Advantage

Most automotive applications benefit from hybrid designs. We use rigid sections where components need stable mounting and flexible sections where movement occurs. This approach has been particularly successful for:

Camera modules that need precise alignment

Sensor clusters in active suspension systems

Battery management systems in EVs

Manufacturing Considerations

The transition to flexible PCBs requires manufacturing adjustments. We've learned to:

Work with laser cutting specialists to maintain ±0.05mm tolerances

Implement automated inspection to catch microscopic defects

Use specialized fixtures for assembly to prevent stress during manufacturing

The data from production vehicles confirms what we suspected. One electric vehicle manufacturer reported:

35% reduction in wiring-related warranty claims

28% faster assembly times for complex modules

2.1kg weight reduction per vehicle

Improved reliability in temperature cycling tests

Another manufacturer found that flexible PCBs in their ADAS systems provided more consistent signal integrity, particularly for high-speed camera data.

Thermal Management

Early designs struggled with heat dissipation in power applications. We solved this by:

Using thermal vias to transfer heat to larger areas

Incorporating heat-spreading layers in multi-layer designs

Working with thermal management specialists on critical applications

Connector Reliability

The transition areas between flexible and rigid sections require special attention. We've had success with:

Gradual thickness transitions over 3-5mm distances

Strategic reinforcement with polyimide stiffeners

Extensive testing of solder joint reliability under vibration

The evolution continues. We're now working on:

Integrating more functions into single flexible circuits

Developing better testing protocols for autonomous vehicle applications

Creating design guidelines for next-generation vehicle architectures

What started as a solution to vibration problems has become a fundamental enabler of automotive innovation. Flexible PCBs aren't just another component - they represent a new way of thinking about vehicle electronics.

For engineering teams willing to embrace this approach, the benefits are substantial: improved reliability, reduced weight, and greater design freedom. More importantly, they provide a pathway to solving the complex electronic packaging challenges of next-generation vehicles.

The companies that master flexible PCB technology today will be the ones leading the automotive industry tomorrow.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..