Date: 2025-10-22

If you've ever been called to a production line because a robot joint failed during critical operation, you understand the frustration. I recall a automotive welding line where cable failures in the sixth axis were shutting down production every three months. The solution we developed with rigid-flex PCBs didn't just fix the problem - it transformed how we approach robotic wiring entirely.

Industrial robots face wiring demands that would destroy most electronic systems. In a typical six-axis robot, the third axis alone might complete over two million cycles annually. Traditional wiring approaches simply can't keep up.

The Fatigue Failure Pattern

Through failure analysis, we identified that most cable failures occur within 5mm of connectors or at fixed bend points. The constant stress concentration at these locations leads to conductor fatigue that standard cables can't withstand. I've examined cables from collaborative robots that showed complete conductor fracture after just 40,000 cycles.

Space Constraints in Modern Robotics

Today's robots are getting more compact while requiring more electronics. I recently worked on a delta robot where the available wiring space was only 12mm in diameter. Traditional cabling would have occupied 9mm of that, leaving almost no room for cooling or mechanical components.

The Mechanical Advantage

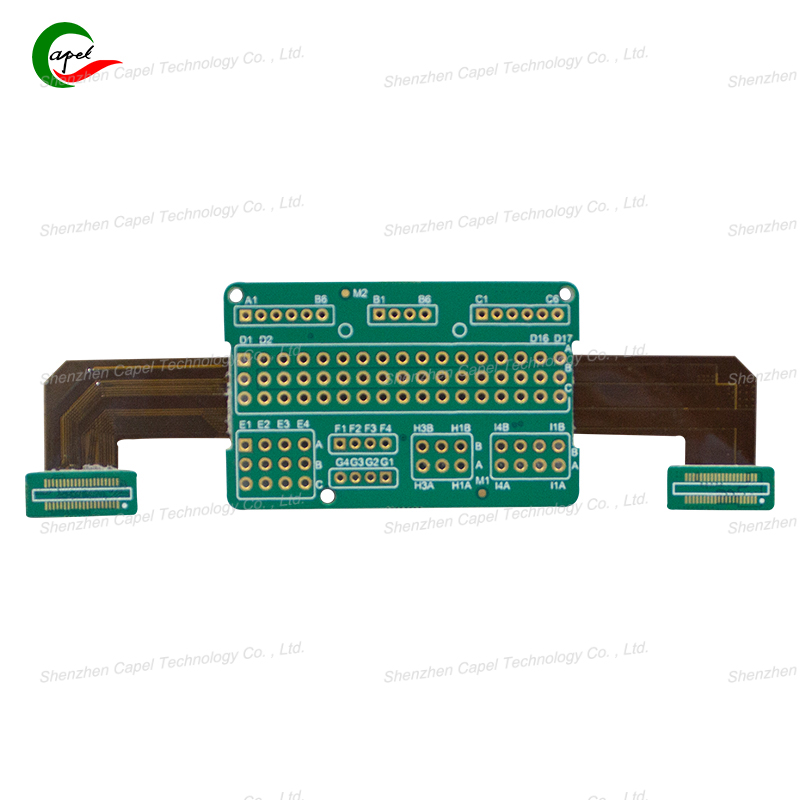

The integration of rigid and flexible sections creates a fundamentally different mechanical behavior. Instead of cables bending at random points, rigid-flex PCBs bend only where designed. This controlled flexibility eliminates the stress concentrations that cause premature failures.

We've tested rigid-flex designs through over 500,000 bend cycles without failure - a 5x improvement over the best robotic cables available.

Space Optimization That Matters

In one SCARA robot application, we reduced the wiring bundle from 14mm to 6mm diameter using rigid-flex technology. This allowed the manufacturer to increase the robot's working range by 8 degrees while improving cable management.

Material Selection for Robotic Environments

Through extensive testing, we've found that certain material combinations work exceptionally well for robotic applications:

Liquid crystal polymer (LCP) substrates for high-frequency applications

Rolled copper with 25μm thickness for dynamic flexing

Polyimide with 260°C thermal stability for welding applications

Design Principles That Work

The transition between rigid and flexible sections is critical. We use:

4mm tapered transitions for high-cycle applications

Strategic stiffeners in component areas

Neutral axis routing for critical signals

One particularly successful design for an articulated welding robot used a spiral flexible section that could handle complex three-dimensional movement while maintaining signal integrity.

Manufacturing Considerations

Robotic applications demand exceptional reliability. We implement:

100% automated optical inspection

Cross-section analysis of via structures

Extended thermal cycling before shipment

The data from field installations demonstrates the impact:

A major automotive manufacturer reduced welding robot downtime by 73% after switching to rigid-flex solutions

A electronics assembly line saw task errors decrease from 2.1% to 0.7% after implementing rigid-flex wiring

Maintenance intervals extended from quarterly to annual in multiple applications

One collaborative robot manufacturer reported saving $12,000 annually per unit in maintenance costs while improving positioning accuracy by 18%.

Thermal Management

Early designs struggled with heat dissipation in sealed joint spaces. We solved this by:

Incorporating thermal vias in rigid sections

Using thermally conductive adhesives

Optimizing power distribution to reduce localized heating

Signal Integrity

High-speed communication in dynamic applications requires special attention. Our solutions include:

Matched impedance design throughout flexible sections

Strategic ground plane placement

Extensive testing under operating conditions

Start with the Highest-Value Applications

We typically begin with:

Sixth axis wiring in articulated robots

SCARA robot Z-axis applications

Collaborative robot elbow joints

Build Prototypes Early

Physical testing is essential. We create functional prototypes that undergo:

Accelerated life testing to 100,000+ cycles

Environmental testing including thermal cycling

Vibration testing simulating actual operating conditions

The technology continues to evolve. We're currently working on:

Integration of power and data in thinner profiles

Smart flexible circuits with embedded sensors

Advanced materials for even longer service life

Rigid-flex PCBs represent more than just a wiring solution - they enable fundamentally better robotic designs. The reliability improvements, space savings, and performance gains we've documented make a compelling case for their adoption in demanding robotic applications.

For engineering teams working on next-generation robotics, mastering rigid-flex technology provides a competitive advantage that translates directly to improved reliability and reduced total cost of ownership.

The companies that embrace this approach today will be the ones setting the standards for robotic reliability tomorrow.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..