Date: 2025-11-10

Let's talk about 20-layer flexible printed circuits (FPCs). These aren't your average flex boards. They're the high-density, complex wiring that fits into the tightest spaces, powering stuff like satellites, advanced medical scanners, and top-tier displays. Making these isn't for the average circuit board shop. The technical bar is sky-high. Knowing what makes a factory capable of this helps you pick the right partner and avoid costly mistakes.

The High Bar: What It Really Takes to Make 20-Layer FPCs

The "multi-layer" part is the real challenge. A factory must conquer three major hurdles:

Precision Alignment: Imagine stacking 20 ultra-thin, flexible circuit layers and trying to get all the microscopic holes and lines to match up perfectly. If they're off by a hair, you get shorts or broken signals. This requires crazy-precise lamination equipment and automated optical alignment systems. The level of precision and operator skill needed here is in a different league compared to standard multi-layer FPCs.

Micro-Via Drilling: To connect all these layers, you need thousands of tiny, blind and buried vias—way smaller than what mechanical drills can handle. This demands advanced laser drilling systems. The factory must consistently produce clean, smooth holes without any rough edges inside that could cause electrical shorts down the line.

Material Know-How: You're dealing with a stack of different materials—various polyimide films, adhesives, and copper. They all expand and contract differently under heat and pressure. The manufacturer needs deep experience (gained from years of trial and error) to choose the right combination that won't delaminate, bubble, or warp during the high-pressure lamination process. This is as much an art as it is a science.

What a True 20-Layer FPC Factory Looks Like

If a factory can reliably produce these boards, they'll have these key capabilities:

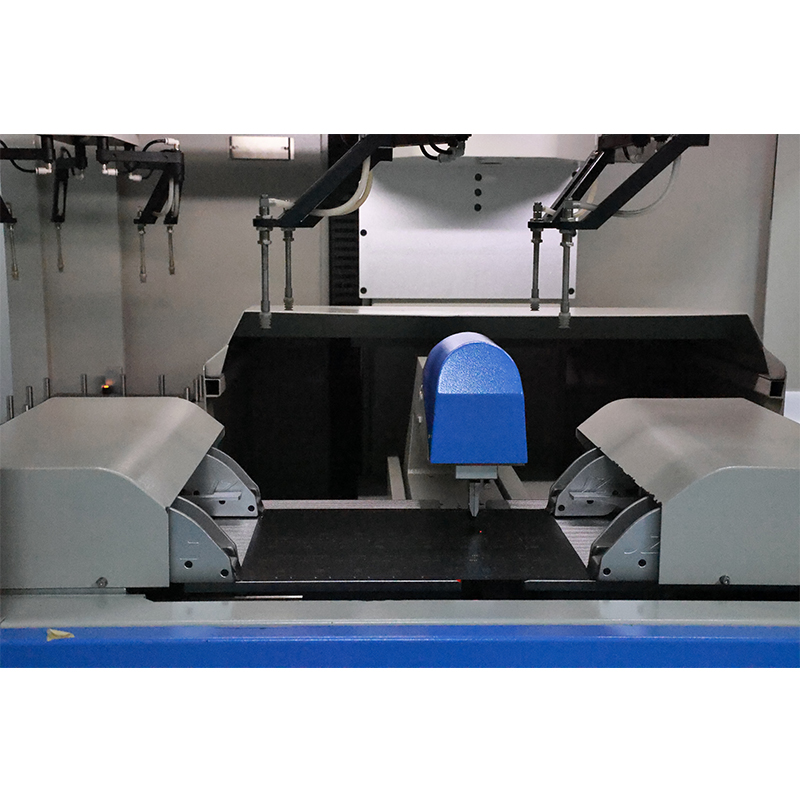

Top-Tier Equipment: This isn't a shop with a few basic machines. We're talking a full line of high-end gear: laser cutters, vacuum laminating presses (to squeeze out all the air between layers), and sophisticated electrical testers to check signal integrity across all 20 layers. A single one of these machines can cost more than an entire standard FPC production line.

A Relentless Focus on Quality: They can't afford to "ship and hope." The process is littered with checkpoints. They'll use Automated Optical Inspection (AOI) to scan every layer after it's etched. The finished boards will be put through torture tests—thermal cycling, bend testing—to ensure they'll survive in the real world. Consistent, high yield is the name of the game.

Customization is Standard: Nobody orders a 20-layer FPC off the shelf. These are all custom projects. The factory needs a strong engineering team that can work with you to design the stack-up, select materials for your specific needs (like signal speed or temperature range), and run small pilot batches to prove the process works before going to full-scale production. This de-risks the entire project for you.

Where These Complex FPCs Actually Get Used

You'll find these boards in places where failure is not an option:

Aerospace & Defense: In satellites and military drones, where electronics must endure extreme vibration and radiation. The FPC integrates power, data, and control lines into one reliable package.

High-End Medical Imaging: Inside MRI machines and surgical robots, where multiple sensor signals need to be transmitted simultaneously without any cross-talk or delay, ensuring diagnostic accuracy and surgical precision.

Premium Displays: For 8K+ screens, where the driver circuitry requires an immense number of connections in a tiny space. The 20-layer FPC provides the necessary routing density to prevent signal lag or distortion.

What Kaboer Brings to the Table in 20-Layer FPC Manufacturing

Shenzhen Kaboer Technology Co., Ltd. has been specializing in the tough stuff—specialty FPCs—for over 16 years. We're a one-stop shop that handles design, R&D, manufacturing, and sales.

Our setup is built for custom work. We operate what we call a "specialized campus + vertical tech team" model. This means we have six dedicated factory areas, each focused on a different part of the process and product range:

FPC Quick-Turn Prototypes

FPC Mass Production

Multi-layer & Rigid-Flex Boards

Specialty PCBs

SMT Assembly

Plating

This structure lets us tackle complex projects from any angle. Whether you need a few prototypes for R&D or full-scale production runs, our teams across these specialized facilities work together to cover the entire FPC spectrum. We provide tailored solutions for critical industries like aerospace, automotive, medical, and industrial automation.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..