Date: 2025-11-10

Let's break down how these heat-managing circuit boards are actually constructed. At its heart, an aluminum board is a simple but brilliant three-layer sandwich. Each layer has a very specific job, and they work together to solve one problem: getting heat away from your components while keeping the electricity where it's supposed to be.

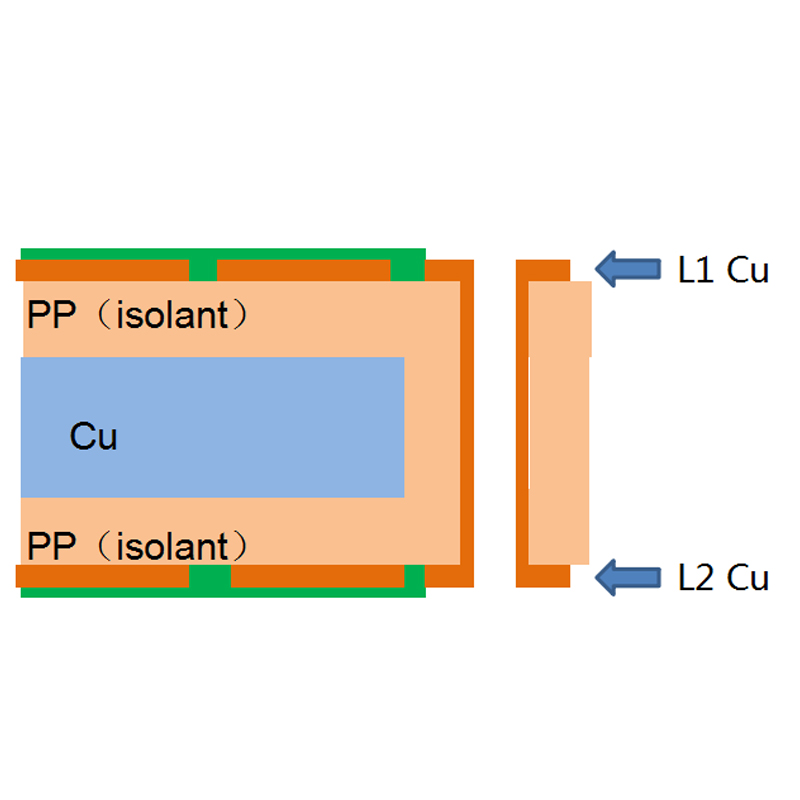

The Three Must-Have Layers (From Bottom to Top)

The Metal Core (The Heat Sink Layer)

What it is: This is a thick slab of aluminum (usually types like 6061 or 5052). For extreme cases, a copper core is used, but it's more expensive.

How thick: Typically between 1.0mm and 2.0mm. The thicker it is, the more heat it can soak up and spread out. For slim devices, you can find thinner versions.

Its real job: This is the board's built-in heat sink. It absorbs the heat coming down from the components and spreads it out over its large area, often transferring it to the device's case or an external heat sink.

The Dielectric Layer (The Magic Middle)

What it is: A thin, specially formulated layer filled with ceramic particles (like alumina or boron nitride) in a polymer base. It's a superhero material that has to do two opposite jobs perfectly.

How thick: Very thin, usually 0.15mm to 0.2mm. Too thick and it blocks heat; too thin and it might not insulate properly.

Its real job: This is the most critical part. It must be a perfect electrical insulator to prevent the circuit from shorting to the metal base, while also being a fantastic thermal conductor to shuttle heat down to that same metal base. The quality of this layer (its thermal conductivity rating from 1 to 10 W/m·K) is what makes or breaks the entire board's cooling performance.

The Circuit Layer (The Brain Layer)

What it is: A layer of copper foil, just like on any standard PCB.

How thick: Usually 1oz (0.035mm), but thicker 2oz or 3oz copper is used for high-current paths.

Its real job: This is where the electronics live. You etch your traces, place your solder pads, and mount your components like LEDs, resistors, and chips. It handles all the electrical signaling. To keep heat moving efficiently, the circuit layer is often kept to a single side.

The Optional Add-Ons (Depending on Your Needs)

Solder Mask: That green (or other color) coating on top of the copper. It prevents solder bridges and protects the copper traces. It's left open over the pads where you need to solder components.

Silkscreen: The white lettering that shows component designators ("R1", "C5") and orientation marks. It's just for helping humans during assembly and repair.

Stiffeners: Small pieces of FR4 or metal added to areas like connectors. They provide extra mechanical support for parts that will be plugged and unplugged repeatedly, without hurting the overall board's ability to shed heat.

Thermal Interface Materials: Pads, paste, or tape applied to the back of the metal core. These fill microscopic air gaps when you bolt the board to a heat sink, dramatically improving the heat transfer out of the board.

Why This Simple Structure Works So Well

The genius is in the collaboration:

The Circuit Layer holds the hot components.

The Dielectric Layer safely and efficiently grabs that heat and passes it down.

The Metal Core absorbs and spreads the heat like a champion.

This creates a direct, low-resistance path for heat to travel: Heat Source -> Circuit Layer -> Dielectric Layer -> Metal Core -> The Outside World.

The Bottom Line:

The dielectric layer is the bottleneck and the hero. A standard board might use a cheaper dielectric with lower thermal performance. For a high-power LED or a power transistor, you'd want a premium, ceramic-filled dielectric to get the heat out as fast as possible. This simple, focused three-layer structure is why aluminum boards are the undisputed choice for keeping high-power electronics cool and reliable.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..