Date: 2026-01-17

Picture these situations:

Your circuit board visibly sags in the middle after mounting a large heatsink

Solder joints develop fine cracks during vibration testing

The board heats up too quickly when power components operate

A large board feels "flimsy" or unstable

If you've encountered these issues, a thick PCB might be the solution. But first, let's clarify what "thick" actually means.

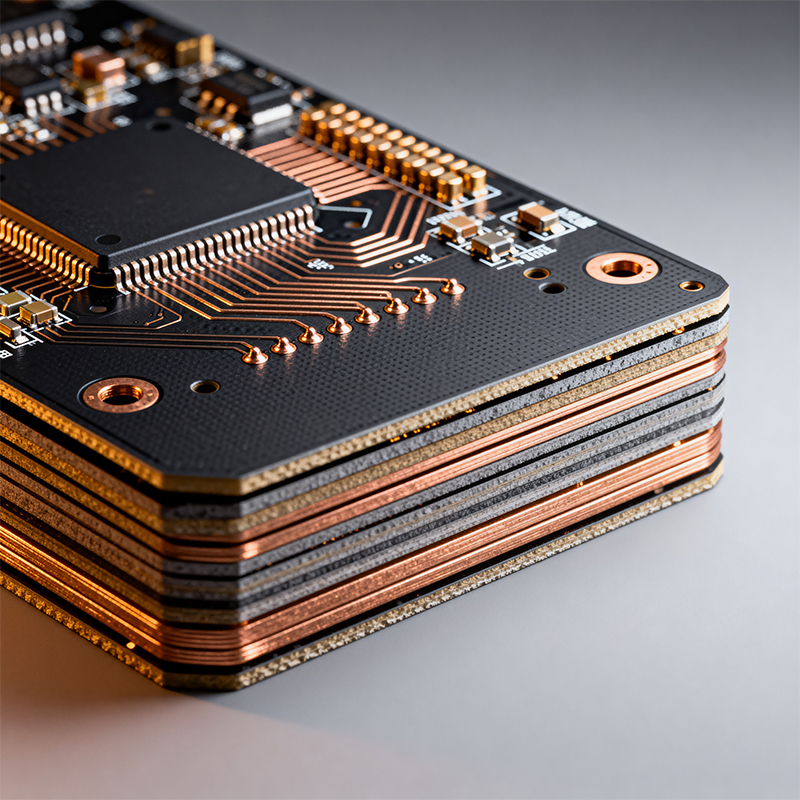

1.6mm - Industry standard, chosen for 90% of consumer electronics

2.0mm - Entering "thick board" territory, a common upgrade choice

2.4mm - Typical for industrial applications

3.0mm and above - For special needs like heavy-duty equipment or extreme environments

These measurements refer to the total finished thickness, including all insulating layers, copper layers, and protective coatings.

A thick board is like thicker steel—it better:

Resists bending and deformation, especially in large designs

Supports heavy components (think large transformers or heatsinks)

Maintains flatness when secured with multiple screws

Protects solder joints in vibrating environments

Real Case: An industrial controller client found cracks around BGA chips after vibration testing on 1.6mm boards. After switching to 2.4mm boards, they passed all tests.

Thicker material means:

Greater thermal mass, slower temperature rise

Better heat distribution, preventing hot spots

A more stable foundation for cooling solutions

Note: If heat dissipation is the primary concern, metal-core boards might be more suitable. Thick FR-4 boards strike a balance between cost and performance.

In some designs, thickness affects:

Interlayer insulation (important for high-voltage applications)

Impedance control accuracy (critical for RF circuits)

Signal integrity (reduced crosstalk)

Switching power supplies, UPS systems, power converters—these typically need to:

Carry high current through thick copper traces

Support heavy magnetic components

Manage heat effectively

PLCs, motor drives, automation controllers face:

Continuous vibration in factory environments

Extreme temperature variations

Reliability requirements spanning years

Particularly modules near engine compartments:

Constant vibration during vehicle operation

Temperature ranges from -40°C to 125°C

Reliable installation in confined spaces

Oscilloscopes, spectrum analyzers, precision measuring equipment:

Extremely sensitive to微小变形

Require long-term stable measurement platforms

Often include heavy connectors

High-power LED fixtures:

Need to quickly conduct heat away from chips

Support external heat dissipation structures

Resist environmental temperature changes

Materials suitable for regular boards might not work for thick ones:

Prepreg resin content must be just right

Thermal expansion coefficients should match across layers

Special lamination processes might be needed

Drilling small holes in thick boards is more challenging:

Requires sturdier drill bits

Speed and feed rates need recalibration

Hole wall quality needs special attention

Deep holes may require special techniques

Ensuring even copper coverage inside holes:

Plating solution circulation must be thorough

Current distribution might need optimization

Center sections often risk insufficient copper thickness

Thick boards warp more easily because:

Temperature differences between inner and outer layers are greater during cooling

Effects of material asymmetry are amplified

Control is needed from both design and process perspectives

Material costs: 20%-100% more material used

Processing costs: Longer manufacturing time, more complex process control

Testing costs: Possibly more testing to ensure quality

Yield: Initial production yield might be lower

Lead time: May require longer production cycles

Minimum order quantity: Some factories have higher MOQs for thick boards

Price Reference Range:

2.0mm boards: 15%-30% more expensive than 1.6mm

3.0mm boards: 40%-80% more expensive than 1.6mm

Specifics depend on design complexity and order quantity

Answer these questions honestly before deciding:

How heavy is the heaviest component? Over 50g warrants considering thick boards

How large is the board? Length over 20cm suggests considering thicker options

What's the vibration environment? Continuous vibration requires more robust designs

How many mounting points are there? Multiple fixation points demand better flatness

What's the power density? High heat density needs better thermal management

What's the operating voltage? High-voltage applications require thicker insulation

What's the expected lifespan? 10+ year lifespans demand more reliable structures

What's the budget? Is the cost increase acceptable?

If three or more answers point toward needing reinforcement, thick boards deserve serious consideration.

If budget is tight or only局部 areas need reinforcement, consider:

Increase thickness in specific areas (step-board design)

Add metal stiffener bars

Use support pillars or stiffeners

Adjust component placement to reduce concentrated loads

Optimize fixation point locations and quantity

Select appropriate material grades

Employ better soldering processes

Add protective coatings

Improve heat dissipation paths

When you decide to use thick boards, asking these questions yields more useful information:

Ask about capabilities:

"What thicknesses do you most commonly produce?"

"What's your lamination process for 2.4mm boards?"

"What special measures do you take for drilling and plating thick boards?"

Ask about quality:

"How do you control warpage in thick boards?"

"How do you ensure plating uniformity in thick boards?"

"What special tests do you perform on thick boards?"

Ask practical questions:

"Based on my design, what thickness would you recommend?"

"How does increased thickness affect lead time?"

"How feasible is small-batch production of thick boards?"

Use standard boards for functional verification

Assess mechanical and thermal requirements

Determine if thickening is necessary

Produce test boards in 2-3 thicknesses

Conduct mechanical, thermal, and electrical tests

Collect actual data for decision-making

Produce 50-100 boards at final thickness

Complete comprehensive testing and reliability verification

Confirm design and process feasibility

Optimize production processes

Establish quality control standards

Prepare for volume manufacturing

Thick PCBs aren't a simple case of "thicker is better"—they're an engineering decision for specific needs. They address mechanical strength, heat dissipation, and stability issues but increase cost and manufacturing complexity.

The best choice starts with clear requirements analysis. Understand what environment your product will face, what stresses it must endure, how long it needs to work, then select the thickness that just meets these needs—not insufficient, not excessive.

Remember, good design isn't about using the thickest board, but the most appropriate one. Sometimes, clever design optimization is more effective and economical than simply adding thickness.

If you're hesitating between several thickness options, a simple principle is: start with the thinnest design that achieves functionality, and only increase thickness when testing proves it necessary. This controls costs while ensuring reliability.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..