Date: 2026-01-17

When a circuit board stops working, your first thought might be "Should I fix it or replace it?" In electronics manufacturing, the answer to this question often affects cost control and production efficiency. Today, let's talk about how to professionally repair circuit boards—not simple replacement, but real diagnosis and repair.

Before picking up tools, ask yourself:

Value of the faulty board: Is repair cost lower than replacement cost?

Severity of failure: Single component failure or multiple faults?

Time urgency: Time available for repair or need immediate replacement?

Future reliability: Can repaired board meet original reliability standards?

High-value boards: Server motherboards, industrial controllers, medical equipment core boards

Hard-to-replace boards: Custom designs, discontinued models

Sample boards from batch failures: Representative boards for root cause analysis

Extensive physical damage: Broken boards, internal layer damage in multilayer boards

Severe corrosion or burn damage: Large area damage involving multiple regions

Excessive repair cost: Estimated repair exceeds 60% of new board cost

Quality soldering equipment

Temperature-controlled soldering iron (recommended 60-80W, adjustable temperature)

Hot air rework station (for desoldering multi-pin components)

Solder sucker or desoldering braid

Measurement instruments

Digital multimeter (with capacitance, diode testing functions)

Optional: Oscilloscope (for signal analysis)

Magnification equipment

Magnifying glass or stereo microscope (at least 10x magnification)

Good lighting (LED strips or ring lights)

Chemicals

No-clean flux

Isopropyl alcohol (for cleaning)

Anti-static brushes

In-circuit tester (ICT)

X-ray inspection equipment

Thermal imaging camera

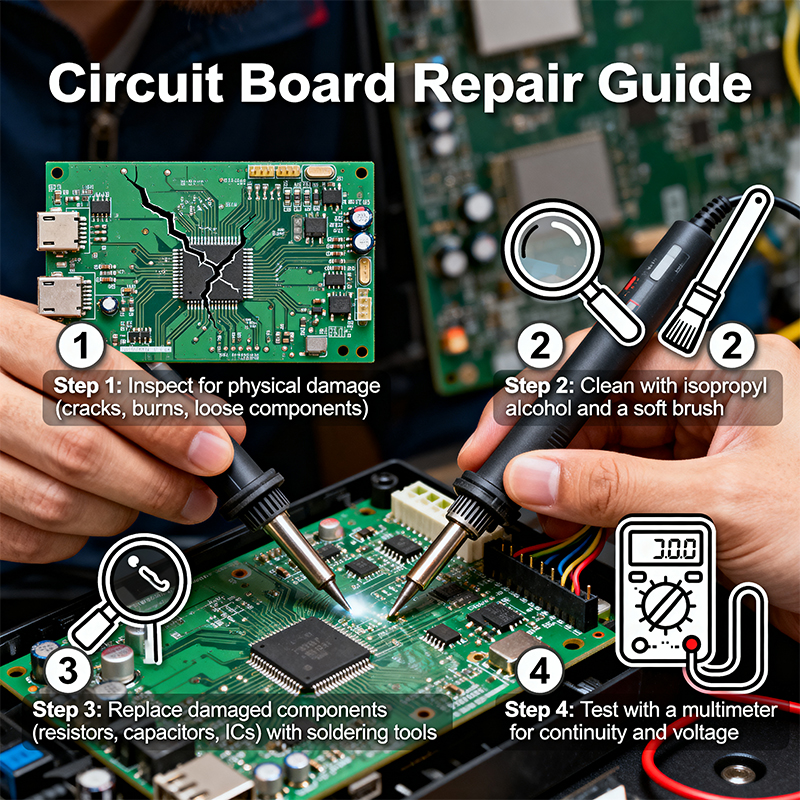

Before powering up, examine carefully under magnification:

Physical damage: Cracks, bends, broken traces

Component abnormalities: Bulging capacitors, burnt resistors, cracked chips

Solder issues: Cold joints, bridges, poor connections

Corrosion signs: Especially around connectors and moisture-sensitive areas

Previous repair marks: Check if previous repairs were professional

Practical tip: Shine a flashlight at different angles across the board; shadows highlight uneven surfaces and tiny cracks.

Many faults are caused by contaminants:

Gently remove dust with a soft brush

Clean suspicious areas with isopropyl alcohol and cotton swabs

For stubborn stains, consider ultrasonic cleaning (risk of damaging some components)

Safely conduct:

Power short test: Check for shorts between power and ground with multimeter

Key point resistance: Measure resistance to ground at key test points, compare with good board

In-circuit component testing: Test diodes, transistors, etc., without removing them

Safety warning: Ensure board is completely powered down and discharged (especially large capacitors) before testing.

Start with most likely problem areas:

Check all voltage regulator outputs

Measure supply pin voltages on major chips

Check power ripple and stability

Confirm main clock signal exists with correct frequency

Check reset signal is normal

Trace key signals (data lines, address lines)

Check interface connectors

Desoldering techniques:

For multi-pin ICs, use hot air with appropriate nozzle

Apply heat evenly to avoid localized overheating

Use flux to aid solder melting

Soldering new components:

Clean pads, ensure no solder residue

Align polarity (reference silkscreen markings)

Use appropriate temperature and duration

Scrape off solder mask at both ends of broken trace to expose copper

Tin the exposed areas for good connection

Connect with fine wire (like enameled wire)

Secure and protect with UV-curing adhesive or solder mask

If pad is completely gone, find where the trace connects

Use fine wire to connect directly to component lead

Secure wire with adhesive for mechanical strength

Clean clogged vias with needle or fine drill bit

Solder from both sides to ensure connection

If necessary, use wire through the via to connect both sides

Repair isn't complete without verification:

Visual check: Confirm repaired areas look proper

Electrical testing: Repeat previous tests, ensure problem resolved

Functional testing: Full functional test if possible

Reliability check: Lightly tap board, wiggle connections to ensure repair is secure

Symptoms: Complete power failure, specific voltage missing, unstable voltage

Common causes: Blown fuse, damaged regulator chip, failed filter capacitor

Repair: Replace damaged components, check loads for shorts

Symptoms: Partial function failure, random crashes, specific operations failing

Common causes: Logic chip damage, corrupted firmware, clock issues

Repair: Replace suspect chips, reprogram firmware, check clock circuits

Symptoms: Signal distortion, excessive noise, abnormal gain

Common causes: Damaged op-amps, reference voltage drift, passive component degradation

Repair: Replace op-amps, check reference voltage sources, measure key point voltages

Symptoms: Visible cracks, breaks, bending

Common causes: Mechanical stress, thermal cycling, improper handling

Repair: Wire jumpers, epoxy reinforcement, structural support

Symptoms: Green or white powder, poor connections, leakage

Common causes: Moisture, contaminants, electrolytic corrosion

Repair: Thorough cleaning, replace affected components, apply protective coating

BGA (Ball Grid Array) chip repair requires more skill:

Precise heating: Use preheater and hot air station with controlled temperature profile

Alignment techniques: Use magnification and alignment marks

Solder ball repair: For missing or damaged balls, reballing may be needed

When faults are in internal layers:

Locate fault through testing

Carefully drill to fault layer (avoid damaging other layers)

Connect using micro-wires

Fill hole with epoxy resin to restore insulation

Flex boards need special handling:

Use low-temperature solder to reduce thermal stress

Special flex board adhesives

Add mechanical support after repair

Basic function verification

Continuous operation test (at least 24 hours)

Temperature cycling test (if applicable)

Does repaired area withstand mechanical stress?

Are materials used compatible?

Does repair introduce new failure points?

Whether repair is successful or not, document:

Fault symptoms

Root cause found

Repair actions taken

Test results

Any remaining risks

These records are valuable for preventing future faults and improving designs.

Use anti-static wrist straps and mats

Ensure good ventilation to avoid inhaling solder fumes

Wear safety glasses to prevent solder splashes

Wear gloves when handling old boards that may contain hazardous materials

Confirm test equipment settings to avoid overload

Be aware of high-voltage areas on boards

Use appropriate precautions when repairing sensitive circuits

While many repairs can be done yourself, consider professional service when:

High-precision instrument calibration is involved

Expensive specialized equipment is needed

Safety-critical systems are involved (medical, automotive, aerospace)

High-risk repairs with no relevant experience

Every faulty circuit board is a learning opportunity. Through repair, you can:

Understand design weaknesses to improve next-generation products

Identify quality issues in supply chain

Train technicians to improve skills

Build repair database to predict and prevent common faults

Effective repair capability is a significant competitive advantage for electronics manufacturers. It not only reduces production costs but also improves customer satisfaction and provides valuable firsthand information for product improvement.

Remember, the best repair is preventive design. After each repair, ask yourself: "Could this fault have been prevented through design improvement?" This way, repair becomes part of continuous improvement, not just fixing.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..