Date: 2026-01-20

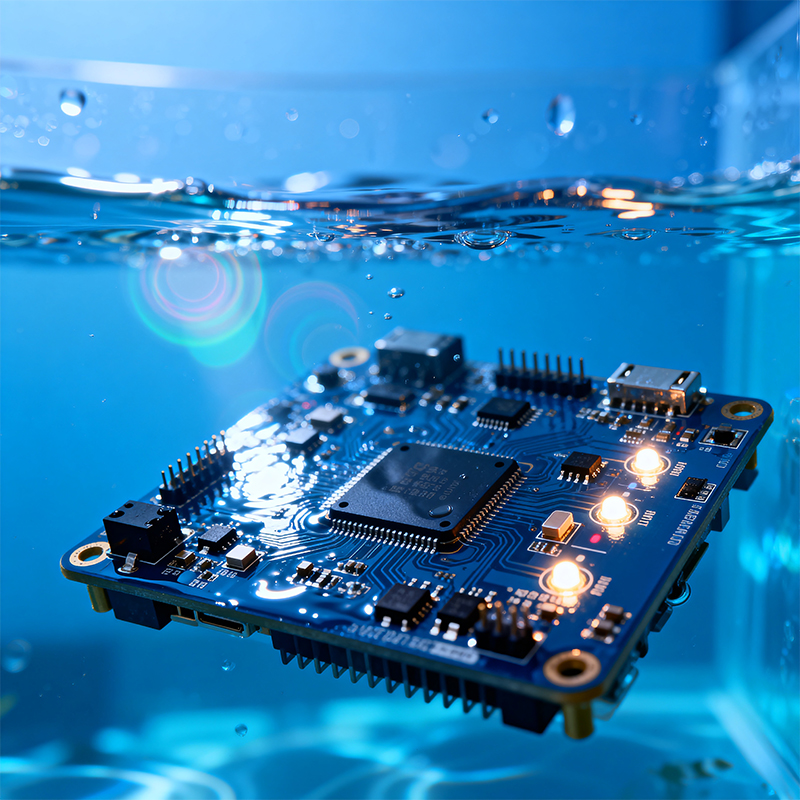

Let's be honest: the real world is messy. Humidity, condensation, accidental spills, and industrial dust don't care about your perfectly designed circuitry. For an electronics manufacturer, this means that waterproofing your circuit boards—or more accurately, making them highly water and contaminant-resistant—isn't a luxury; it's often a basic requirement for reliability.

Think of it as giving your product an invisible shield. This shield is applied after the delicate surface mount pcb assembly is complete and tested. The goal? To prevent the slow, silent killers of electronics: corrosion, short circuits from moisture, and conductive "dendrites" that can grow across damp boards.

Here’s a deep dive into how it’s done, the critical choices involved, and why the assembly process that comes before is just as important as the shield itself.

You have three main paths to choose from, each with its own strengths and trade-offs.

Imagine spraying a thin, transparent, protective film directly onto your assembled board. That's conformal coating. It's like a high-tech raincoat for your electronics.

The Process: After a thorough cleaning (critical for good adhesion), a liquid polymer is applied. This can be done by spraying, brushing, or, for best precision, by a machine that selectively coats only the necessary areas. It then cures into a solid film.

The Materials: You'll typically choose between:

Acrylic: Easy to apply and repair, good general protection.

Silicone: Flexible and great for high-temperature or high-vibration environments.

Urethane: Offers the toughest chemical and abrasion resistance.

Best For: Devices facing humidity, condensation, or mild chemical exposure—think automotive control units, kitchen appliance PCBs, or indoor agricultural sensors. It’s a cost-effective first line of defense that keeps components visible and somewhat repairable.

This is the ultimate protection. The entire board assembly is placed in an enclosure and filled with a liquid compound that hardens into a solid block, completely encasing everything.

The Process: It’s a meticulous operation. The compound (like epoxy, silicone, or polyurethane) is carefully mixed, often de-aired in a vacuum chamber to remove bubbles, and then poured. It must flow into every crevice before curing.

The Reality: This process is permanent and irreversible. It provides unbeatable mechanical strength, moisture resistance, and excellent heat dissipation out of the board. However, it adds weight and makes any repair impossible by design.

Best For: Extreme environments. If your product will be submerged, subjected to high-pressure washdowns, experience intense vibration (industrial machinery, vehicle telematics), or needs to be tamper-proof, potting is the answer.

This method focuses not on coating the board, but on creating a perfectly sealed external environment for it.

The Strategy: It uses gaskets, O-rings, sealed connectors, and specialized adhesives to make the product's housing impermeable. Advanced designs include waterproof breathable membranes that allow pressure equalization while blocking water.

The Application: This is the hallmark of consumer electronics like smartwatches, smartphones, and outdoor lights. It protects the user experience (keeping ports functional) and aesthetics while safeguarding the internals.

Best For: High-volume consumer or commercial products where user interaction, aesthetics, and repairability are key. It’s frequently used in combination with a conformal coat for defense-in-depth.

This is the point many underestimate. You cannot simply take any assembled board and decide to waterproof it. The surface mount pcb assembly process and the choice of protection are deeply, critically linked.

The "Point of No Return" with Potting: Once a board is potted, every solder joint, resistor, and chip is buried forever. If there was a weak solder joint hidden under a chip, you'll only discover it when the entire unit fails in the field. Therefore, the SMT process must achieve near-zero defects. This demands rigorous process control, SPI (Solder Paste Inspection), AOI (Automated Optical Inspection), and possibly X-ray for BGAs before the board ever sees potting material.

Material Compatibility is a Minefield: Some conformal coatings can chemically attack or stress-crack certain types of plastic used in component packages. Potting compounds generate heat during curing and exert mechanical stress. Choosing the wrong material can damage the very components you're trying to protect.

Process Flow is King: Connectors, test points, battery contacts, and heatsinks must often remain uncoated. This requires precise masking or selective coating processes that must be planned during the PCB design and assembly planning stages.

This complex interplay is why sourcing waterproofing as a separate, outsourced step after assembly is a risky proposition. It creates a "quality gap" where responsibility is blurred.

An integrated manufacturer that masters both SMT assembly and subsequent protection processes offers a fundamentally more reliable path. This is the model we've built at Kaboer in our Shenzhen facility.

For our clients, this integration translates into tangible benefits that go beyond a simple assembly quote:

Early and Informed Collaboration: Our engineers can provide meaningful Design for Manufacturing (DFM) feedback that considers both optimal assembly and the requirements of your chosen waterproofing method from the very beginning.

Seamless Process Integrity: The board moves from the reflow oven to cleaning, coating/potting, and final testing in a controlled, continuous flow. The team that built it prepares it for protection, ensuring no contamination or damage occurs between stages.

Unified Accountability: With the entire chain under one roof, there is no finger-pointing between an assembler and a coating vendor. One team owns the quality and reliability of the finished, protected assembly. We stand behind the entire process.

The Shenzhen Ecosystem Edge: Being in the global electronics hub gives us direct access to a vast array of material suppliers and specialists. Whether we need a specific-grade potting compound or a custom-molded gasket, we can source and qualify solutions efficiently.

Waterproofing electronic circuit boards is a decisive commitment to product durability. It signals that your device is built for the unpredictable realities of end-use, not just the clean bench of the lab.

The most successful implementations treat protection not as a final add-on step, but as a core design and manufacturing philosophy that begins with component selection and PCB layout. Your choice of manufacturing partner should reflect this holistic view.

Look for a partner who asks detailed questions about your product's environment, who understands the material science behind coatings and potting, and who demonstrates tight control over the foundational SMT process. Because the strongest shield in the world is only as good as the integrity of what it's protecting.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..