Date: 2025-12-26

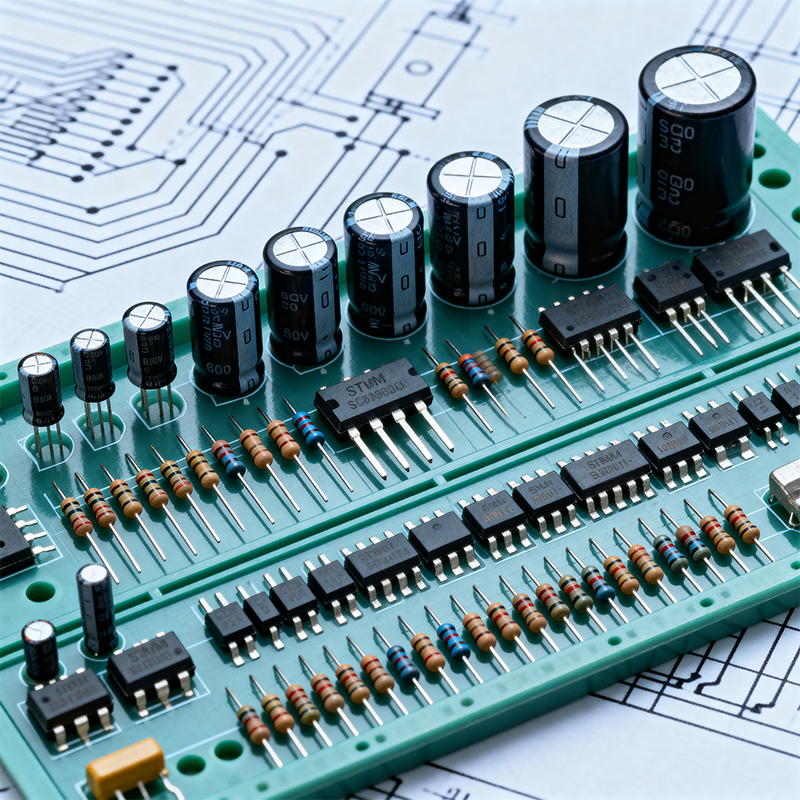

SMT Components, short for Surface Mount Technology Components (also widely known as Surface Mount Devices or SMDs), are the fundamental electronic parts designed specifically for automated assembly onto printed circuit boards. Unlike traditional through-hole components with long wire leads, SMT components feature small metallic terminals or contact pads that allow them to be placed directly onto the surface of a PCB and soldered in place. This design is the cornerstone of modern, miniaturized electronics manufacturing.

An SMT component is defined by its compatibility with Surface Mount Technology assembly processes. Its key physical characteristics include:

Leadless or Flat-Lead Design: Components have short J-leads, L-leads, gull-wing leads, or are entirely leadless with solderable termination pads on their body.

Standardized, Miniature Packages: They are produced in standardized, compact package sizes (e.g., 0402, 0603, QFN, BGA) that facilitate high-density PCB design.

Tape, Reel, or Tray Packaging: For automated handling, SMT components are supplied mounted on tape-and-reel, in plastic trays (waffle packs), or sticks, enabling high-speed pick-and-place machine operation.

SMT components cover the entire range of electronic functions. They are typically classified by their package type, which correlates with their size and assembly requirements.

| Component Category | Common SMT Package Examples | Description & Function |

|---|---|---|

| Passive Components |

Chip Resistors/Capacitors: 01005, 0201, 0402, 0603, 0805 Inductors: Wirewound or multilayer chips |

The most numerous parts on a board. Provide resistance, capacitance, or inductance for circuit biasing, filtering, and energy storage. Smaller sizes (e.g., 0201) enable higher density. |

| Semiconductors (Discrete) |

Diodes/Transistors: SOD-123, SOD-323, SOT-23, SOT-223 LEDs: Chip-scale LED packages |

Used for switching, rectification, protection, and indication. Compact packages save significant board space compared to through-hole versions. |

| Integrated Circuits (ICs) |

Small Outline: SOIC, SOP, TSSOP Quad Flat Packages: QFP, TQFP, LQFP Leadless Packages: QFN, DFN Grid Arrays: BGA, LGA, CSP |

Complex devices like microcontrollers, memory, amplifiers, and processors. QFN/DFN have a central thermal pad for heat dissipation. BGA packages use an array of solder balls underneath for high pin count and performance. |

| Connectors & Electromechanical | Specific SMT footprint connectors (USB, board-to-board), switches, crystals, oscillators. | Components that provide interface, timing, or mechanical function but are designed with SMT solderable terminals instead of through-hole pins. |

The shift from Through-Hole Technology (THT) to SMT represents a fundamental evolution in electronics assembly, driven by distinct technical trade-offs.

| Parameter | SMT Components | Through-Hole Components |

|---|---|---|

| Assembly Method | Mounted and soldered onto the surface of the PCB. | Leads inserted through drilled holes and soldered on the opposite side. |

| Board Real Estate | Extremely efficient. Components can be placed on both sides of the board. | Inefficient. Requires dedicated hole for each lead, limiting routing space. |

| Automation & Speed | Fully automatable. High-speed pick-and-place machines enable very fast assembly. | Partial automation possible for insertion, but often slower and may require manual steps. |

| High-Frequency Performance | Superior. Shorter electrical paths and reduced lead inductance minimize parasitic effects. | Limited. Longer lead wires introduce unwanted inductance and capacitance, degrading RF performance. |

| Mechanical Bond Strength | Good under shear stress, but weaker under direct tensile (pulling) force. | Excellent. Leads through the board provide a very strong mechanical connection. |

| Typical Applications | >90% of modern electronics: smartphones, laptops, wearables, IoT devices. | High-power, high-voltage, or applications where mechanical robustness is the primary concern (e.g., power connectors, large transformers). |

The dominance of SMT components is due to several interconnected benefits for electronic design and manufacturing:

Miniaturization: Enables the production of significantly smaller and lighter end products.

Increased Circuit Density: Allows for more functionality in a given area, supporting advanced features.

Enhanced Electrical Performance: Better suitability for high-speed digital and high-frequency analog circuits.

Streamlined, Cost-Effective Production: Enables fully automated assembly, reducing direct labor costs and increasing throughput, especially for complex boards.

Simplified PCB Fabrication: Eliminates the need for a vast number of drilled holes, reducing board cost and increasing available routing area.

Successfully implementing SMT components requires attention to specific design rules and process controls:

PCB Land Pattern (Footprint): The copper pad design on the PCB must precisely match the component manufacturer's specification to ensure reliable solder joint formation.

Thermal Management: Power-dissipating SMT components (e.g., QFN ICs, regulators) require careful thermal design, often using thermal vias and copper pours connected to their thermal pad.

Solder Paste Stencil Design: The aperture size and shape in the solder paste stencil directly control the volume of solder deposited, which is critical for preventing defects like bridging or insufficient solder.

Moisture Sensitivity: Many SMT ICs (especially BGAs and QFNs) are classified as Moisture-Sensitive Devices (MSDs). They require dry storage and may need baking before reflow to prevent internal cracking ("popcorning").

Q1: What do the numbers in SMT package codes like '0603' mean?

A: For passive chips, the code refers to dimensions. In imperial notation, '0603' means 0.06" long by 0.03" wide. The metric equivalent is '1608' (1.6mm x 0.8mm). For ICs, codes like 'TQFP-64' describe the package style (Thin Quad Flat Pack) and pin count (64).

Q2: Can a PCB use both SMT and through-hole components?

A: Yes. This is called a mixed-technology assembly. The SMT components are placed and soldered first via the reflow process. The through-hole components are then inserted and soldered in a subsequent wave soldering or selective soldering operation.

Q3: How are very small or heat-sensitive SMT components manually repaired?

A: Rework requires specialized tools. A hot air rework station with focused nozzles and precise temperature control is used to safely remove and replace individual SMDs. A temperature-controlled soldering iron with fine tips and micro-soldering techniques is also employed.

Q4: Are there different quality grades for SMT components?

A: Yes. Components are typically graded for different end-use environments:

Commercial: For standard consumer electronics (0°C to 70°C).

Industrial: For wider temperature ranges and harsher conditions (-40°C to 85°C/105°C).

Automotive/Military: For the most rigorous reliability and temperature requirements (e.g., -55°C to 125°C), following standards like AEC-Q100 or MIL-PRF-19500.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..