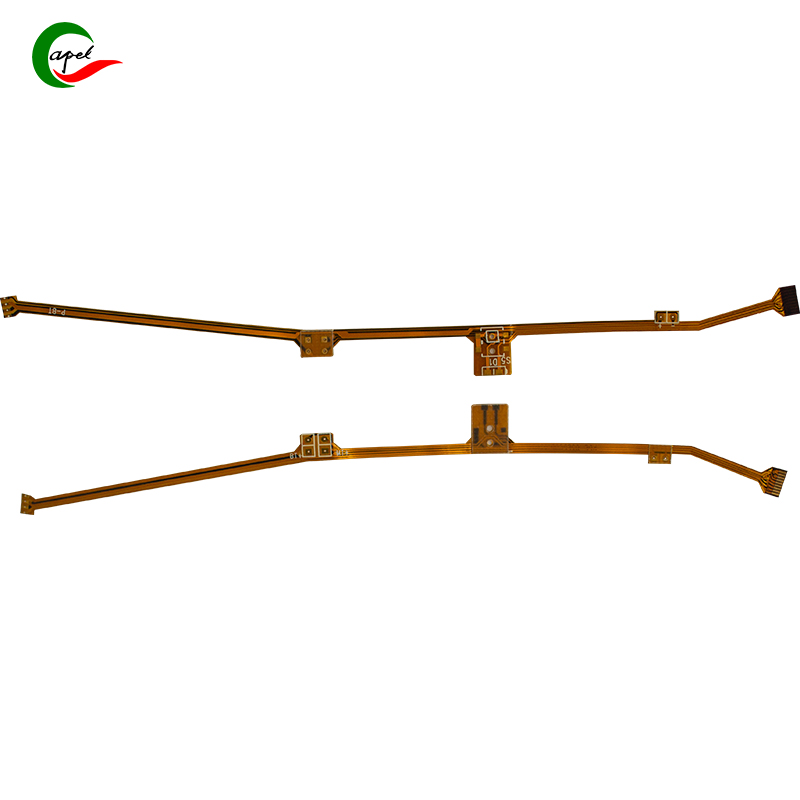

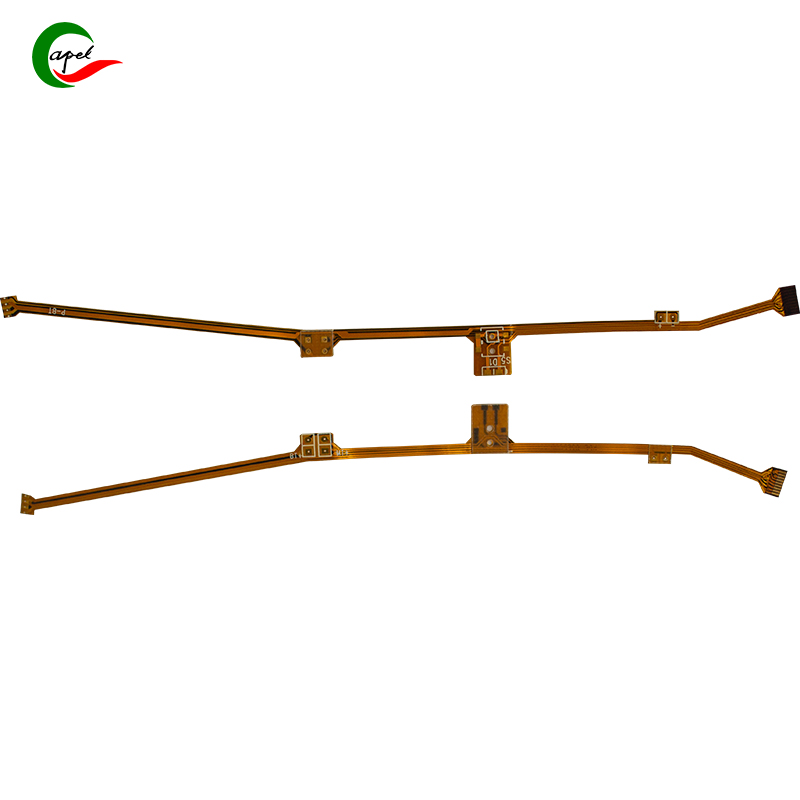

Flexible Printed Circuits (PCBs) have revolutionized the electronics industry with their unique ability to bend, twist, and fit into complex shapes, enabling innovations in various fields from consumer electronics to aerospace. However, their performance and longevity in practical applications are influenced by a multitude of factors. Understanding these factors is crucial for engineers, manufacturers, and users to ensure optimal functionality and reliability of flexible PCBs.

Material Properties

The choice of materials used in flexible PCBs is a fundamental factor that directly impacts their performance and suitability for specific applications.

Substrate materials form the base of flexible PCBs, and their characteristics play a vital role. Common substrate materials include polyimide (PI), polyester (PET), and fluoropolymers. Polyimide is widely preferred due to its excellent thermal resistance, chemical stability, and mechanical flexibility, making it suitable for high-temperature applications such as automotive electronics and industrial machinery. Polyester, on the other hand, is more cost-effective but has lower thermal resistance, making it ideal for less demanding applications like consumer electronics with moderate operating temperatures. Fluoropolymers offer superior chemical resistance but are more expensive, limiting their use to specialized fields.

The conductive materials, primarily copper, also affect the performance of flexible PCBs. The thickness and purity of the copper layer influence conductivity and flexibility. Thicker copper layers provide better conductivity but reduce flexibility, while thinner layers offer enhanced flexibility but may have higher resistance. Additionally, the type of copper coating, such as electrodeposited or rolled copper, can impact adhesion to the substrate and resistance to fatigue from repeated bending.

Adhesives used to bond the substrate and copper layers are another critical material factor. The adhesive must maintain strong bonding under various conditions, including temperature changes and mechanical stress. Poor - quality adhesives can lead to delamination, where the layers separate, resulting in electrical failures and reduced durability.

Environmental Conditions

Flexible PCBs operate in diverse environments, and exposure to different conditions can significantly affect their performance and lifespan.

Temperature is a key environmental factor. Extreme high temperatures can cause the substrate to degrade, reduce the adhesion of layers, and even melt or soften the materials, leading to dimensional changes and electrical issues. Conversely, extremely low temperatures can make the substrate brittle, increasing the risk of cracking when bent. The operating temperature range of flexible PCBs is therefore determined by the materials used, and exceeding this range can severely impact their functionality.

Humidity is another important consideration. High humidity levels can cause moisture absorption in the substrate and adhesives, leading to swelling, reduced insulation resistance, and corrosion of the copper traces. This is particularly problematic in applications such as medical devices used in humid environments or outdoor electronics exposed to rain and dew. Proper sealing and coating of flexible PCBs can help mitigate the effects of humidity.

Chemical exposure can also damage flexible PCBs. Contact with solvents, oils, acids, and other chemicals can degrade the substrate, adhesives, and copper layers, causing swelling, discoloration, and loss of conductivity. Industries such as automotive and industrial manufacturing, where PCBs may come into contact with various fluids, need to select flexible PCBs with chemical - resistant materials.

Mechanical stress from the environment, such as vibration and shock, is a common challenge. In applications like automotive and aerospace, flexible PCBs are subjected to constant vibration, which can lead to fatigue in the copper traces and solder joints, resulting in cracks and electrical failures. The design of the flexible PCB, including the placement of components and the routing of traces, must account for these mechanical stresses to ensure durability.

Design Parameters

The design of flexible PCBs plays a crucial role in their performance and usability.

Bend radius is a critical design factor. The minimum bend radius is the smallest radius to which a flexible PCB can be bent without causing damage. Exceeding this radius can lead to cracking of the substrate, breaking of copper traces, or delamination. The bend radius is determined by the thickness of the PCB, the materials used, and the number of layers. Designers must ensure that the bending requirements of the application are within the specified bend radius of the flexible PCB.

Trace routing refers to the layout of the copper traces on the PCB. Poor trace routing can lead to signal integrity issues, such as crosstalk and impedance mismatch, especially in high - frequency applications. Traces that are too close together can cause interference, while sharp bends in traces can increase resistance and stress, making them more prone to failure during bending. Proper trace routing, including appropriate spacing and gradual bends, is essential for maintaining signal integrity and mechanical strength.

Component placement affects both the electrical and mechanical performance of flexible PCBs. Placing heavy components near bend areas can increase stress on the PCB during bending, leading to damage. Additionally, components that generate a lot of heat should be placed in areas with good heat dissipation to prevent thermal damage to the substrate and other components.

Layer count is another design consideration. Multi - layer flexible PCBs offer higher density and more complex circuitry but are less flexible than single - layer ones. The number of layers must be balanced with the flexibility requirements of the application. Increasing the layer count also increases the thickness of the PCB, which can affect the bend radius and overall flexibility.

Manufacturing Processes

The manufacturing processes used to produce flexible PCBs can have a significant impact on their quality and performance.

Etching is the process of removing unwanted copper to form the traces. Uneven etching can result in irregular trace widths and thicknesses, leading to inconsistent conductivity and increased resistance. Over - etching can thin the traces, making them more prone to breaking, while under - etching can leave excess copper, causing short circuits. Precise control of the etching process is therefore essential.

Lamination is the process of bonding the layers of the flexible PCB together. Poor lamination can result in delamination, where layers separate, due to insufficient adhesion or the presence of contaminants between layers. The lamination temperature, pressure, and time must be carefully controlled to ensure strong bonding.

Solder mask application is used to protect the copper traces from solder bridging and environmental damage. Uneven or incomplete solder mask coverage can leave traces exposed, increasing the risk of short circuits and corrosion. The solder mask must also be compatible with the substrate and other materials to ensure adhesion and durability.

Cutting and forming processes determine the final shape of the flexible PCB. Rough edges from cutting can cause stress concentrations, leading to cracking during bending. Precise cutting techniques, such as laser cutting, can produce smooth edges and ensure accurate dimensions, improving the performance and reliability of the PCB.

Application Requirements

The specific requirements of the application for which the flexible PCB is used also influence its performance and selection.

Electrical requirements, such as current carrying capacity, voltage rating, and frequency, must be matched to the capabilities of the flexible PCB. The copper traces must be designed to handle the required current without overheating, and the insulation must withstand the applied voltage to prevent electrical breakdown. High - frequency applications require careful design to minimize signal loss and impedance mismatch.

Mechanical requirements, including the number of bending cycles, the direction of bending (static or dynamic), and the amount of force applied during bending, are critical. Flexible PCBs used in applications with frequent bending, such as foldable smartphones, must be designed to withstand millions of bending cycles without failure. The choice of materials and the design of the PCB, such as the use of flexible hinges, can help meet these mechanical requirements.

Size and weight constraints in applications like wearable devices and aerospace electronics demand flexible PCBs that are compact and lightweight. The design and manufacturing processes must be optimized to reduce the size and weight of the PCB while maintaining performance.

In conclusion, the use of flexible PCBs is influenced by a complex interplay of material properties, environmental conditions, design parameters, manufacturing processes, and application requirements. By carefully considering these factors, engineers and manufacturers can select or design flexible PCBs that meet the specific needs of the application, ensuring reliable performance and long - term durability. As the demand for flexible electronics continues to grow, a deeper understanding of these factors will be essential for driving innovation and improving the quality of flexible PCB - based products.