Introduction

In the fast-paced world of electronics, innovation often hinges on components that can keep up with evolving design demands. Among these, Flexible PCBs have emerged as a transformative technology, redefining how electronic devices are built and function. Let’s dive into what makes them unique.

Definition: Breaking Free from Rigidity

A Flexible PCB, short for Flexible Printed Circuit, is an electronic component designed to overcome the limitations of traditional rigid circuit boards. Unlike rigid PCBs, which are fixed in shape and constrained by their stiff structure, flexible PCBs are engineered to bend, twist, fold, and conform to even the most complex and irregular shapes. This adaptability makes them a cornerstone of modern, space-efficient device design.

Core Construction: The Building Blocks

The key to a flexible PCB’s versatility lies in its construction:

- Conductive Pathways: Thin layers of copper, the primary conductor, are printed or etched onto the substrate. These pathways carry electrical signals between components.

- Flexible Substrate: The base material is typically polyimide, a robust polymer. It can withstand repeated bending without cracking and offers excellent resistance to heat, chemicals, and electrical insulation—critical for reliable performance in diverse environments.

Key Advantages Over Rigid PCBs

Flexible PCBs stand out for several reasons:

- Space and Weight Savings: They are ultra-thin (often a fraction of a millimeter) and lightweight, making them ideal for compact devices where every millimeter counts.

- Design Freedom: They eliminate the need for bulky wiring harnesses or connectors, snaking through curves and tight spaces to connect components seamlessly.

- Durability: Built to handle thousands—even millions—of bending cycles, they resist cracking under repeated stress, outperforming rigid PCBs in dynamic applications.

- Environmental Resistance: Depending on the substrate and coating, they can withstand humidity, high temperatures, oils, and solvents, ensuring reliability in harsh conditions.

Real-World Applications: Where They Shine

Flexible PCBs are indispensable across industries:

- Consumer Electronics: In smartphones, they link touchscreens, cameras, and batteries within slim, curved bodies. Smartwatches and fitness trackers rely on them to bend comfortably around wrists while maintaining sensor connections.

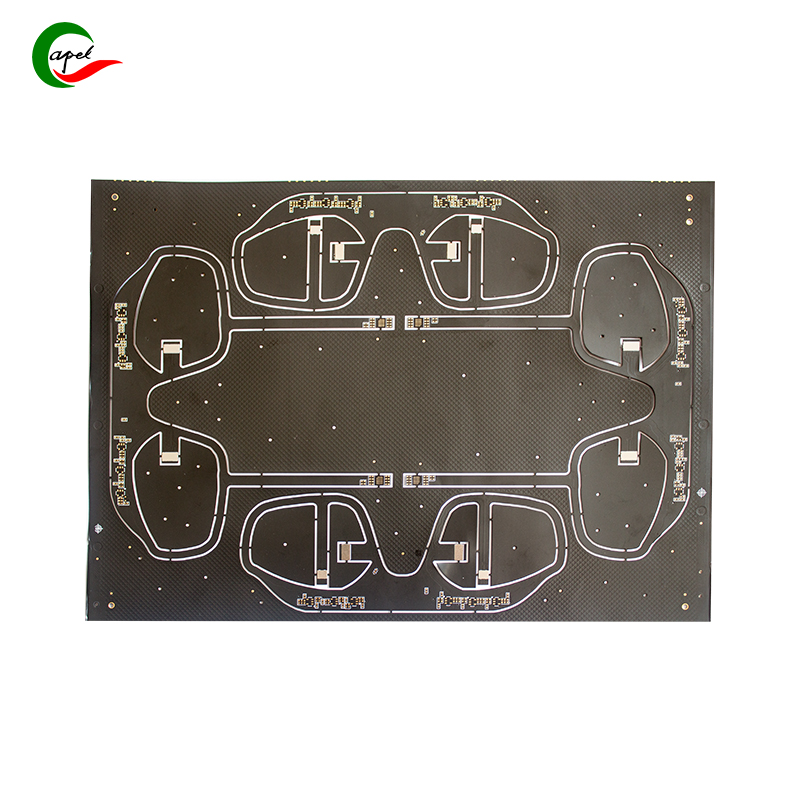

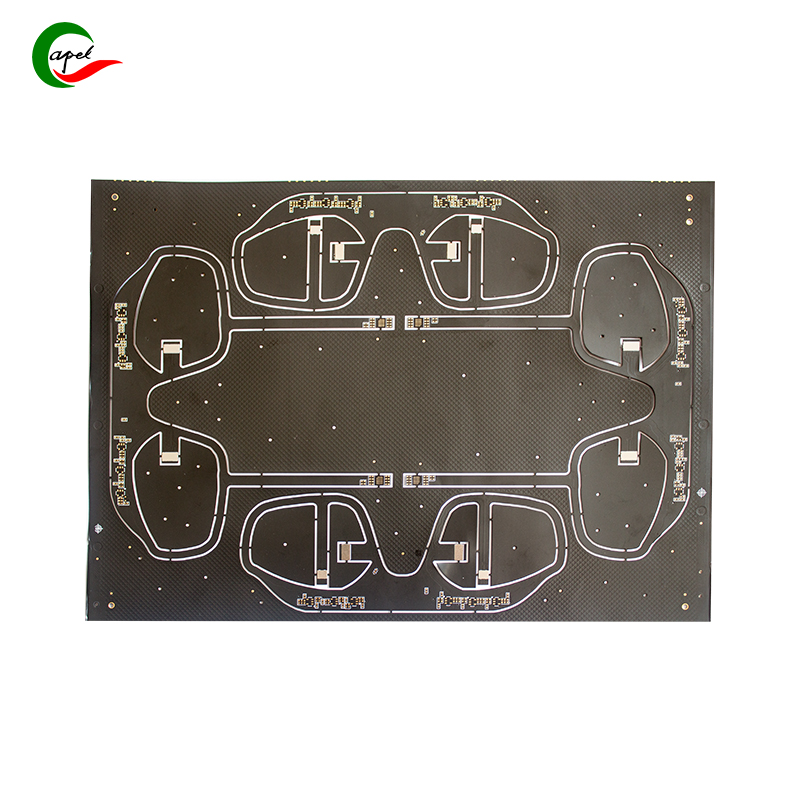

- Automotive Tech: They fit into tight spaces behind dashboards and door panels, connecting infotainment systems, GPS, and advanced driver-assistance systems (ADAS) without adding bulk. Their durability handles vibrations and temperature swings on the road.

- Medical Devices: Used in heart monitors, pacemakers, and portable ultrasound machines, they offer miniaturization and reliability. They integrate into wearable health trackers and precision surgical tools, thriving in sterile environments.

Impact on Manufacturing and Innovation

Beyond functionality, flexible PCBs simplify production:

- They streamline assembly by reducing wiring and connectors, lowering the risk of loose connections or short circuits.

- This efficiency cuts production time and costs, making them a driver of innovation in electronics. From foldable smartphones to lightweight aerospace equipment, they enable designs once thought impossible.

Conclusion

Flexible PCBs are more than just circuit boards—they’re enablers of progress. By blending flexibility, durability, and efficiency, they’ve unlocked new possibilities in device design, making electronics smaller, smarter, and more adaptable. As technology advances, their role in shaping the future of electronics will only grow.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.