Date: 2026-01-04

If you work in electronics manufacturing, you see the term “PCBA Board” all the time. But what is it, really? Is it just that green circuit board?

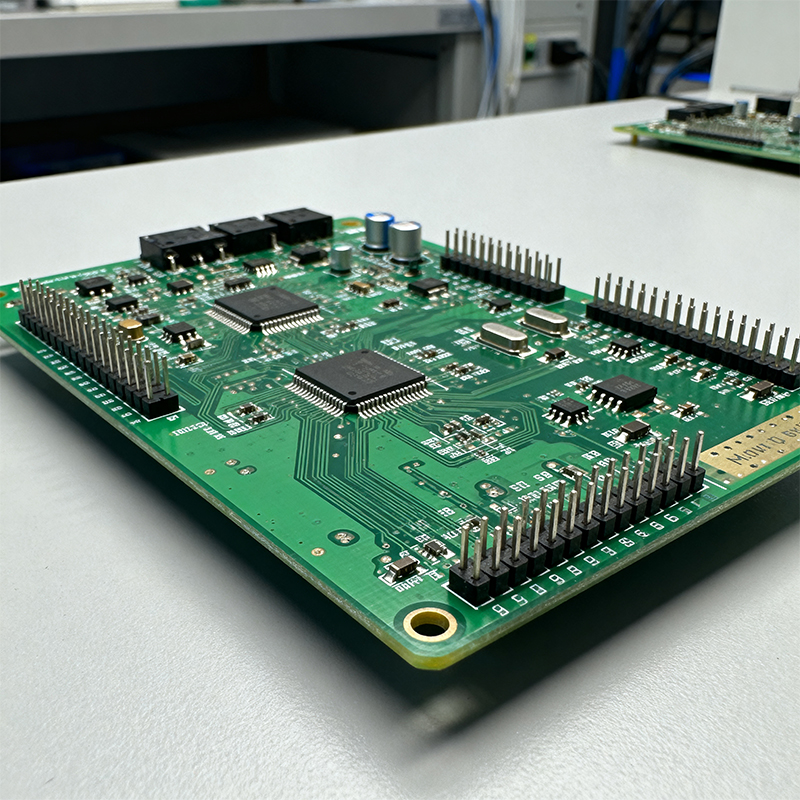

In simple terms, a PCBA Board refers to a Printed Circuit Board Assembly. To clarify, let’s compare it to another term it’s often confused with: PCB.

PCB: This is like a “blank canvas” or the “foundation.” It’s an insulating board with pre-etched copper traces that provide the physical mounting platform and electrical connection pathways for components. By itself, it has no functionality.

PCBA Board: This is the “fully built house” on that foundation. It’s the result of assembling various electronic components—chips, resistors, capacitors, etc.—onto the PCB via processes like surface-mount technology (SMT) or through-hole insertion, followed by soldering. At this stage, the circuit board acquires its specific electronic function, becoming the crucial, “live” core of your product.

So, when you source or discuss a PCBA Board, you are referring to a completed, functional core module—ready for testing and integration into your final product.

In manufacturing hubs like Shenzhen, creating a quality PCBA Board is far more involved than just “soldering parts on.” It’s the result of a series of precise, interconnected steps:

The Starting Point: The process begins with your design files (Gerber, BOM, placement data). A professional manufacturer (like us at Kaboer) will conduct a Design for Manufacturability (DFM) review to identify potential issues before production even starts.

The Core Assembly Phase: Next is the SMT line. High-precision equipment prints solder paste onto the PCB, followed by high-speed placement of tiny components. The board then travels through a reflow oven to form solid solder joints. For through-hole components, a wave soldering process may be used.

The Critical Steps for Reliability: Post-assembly, the board must undergo multiple inspections and tests. This includes AOI (Automated Optical Inspection) for placement defects, possibly X-Ray inspection for hidden solder joints under components like BGAs, and Flying Probe or In-Circuit Test (ICT) to verify electrical connectivity. Finally, Functional Testing ensures the board performs as intended.

Preparing for Delivery: Tested PCBA Boards may then undergo programming, conformal coating (for harsh environments), and are packaged in anti-static materials before being shipped to your assembly line.

Throughout this process, equipment precision, process control, component quality, and a rigorous quality management system together determine the final PCBA Board's performance, reliability, and consistency.

When you need a PCBA Board, what you truly need is for your design intent to be realized accurately, reliably, and cost-effectively. You're not buying an off-the-shelf part; you're commissioning a manufacturing solution.

This is where the choice of manufacturer becomes critical. An ideal partner should function as an extension of your team, capable of:

Understanding Your Requirements: Going beyond just reading the drawings to grasp the product's application and performance goals.

Providing Proactive Manufacturing Insight: Offering optimization advice from a production standpoint during the engineering phase to prevent DFM issues.

Taking Ownership of the Entire Process: Owning the factory means stronger control over quality, lead times, and cost, without the uncertainty and communication gaps that come with outsourcing.

At Kaboer, this is how we operate. Our factory is in Shenzhen—the heart of global electronics manufacturing. This allows us to deeply integrate with the supply chain, respond quickly, and focus our professional engineering and quality control capabilities on transforming your designs into high-quality, reliable PCBA Boards. Having served many international clients like you, we understand the challenges from prototyping to mass production and are committed to being a trusted manufacturing partner through transparent communication and dependable delivery.

If you’re looking for a partner who truly understands PCBA Board manufacturing and can execute it effectively, we’d be glad to start a conversation about your project, regardless of its current stage.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..