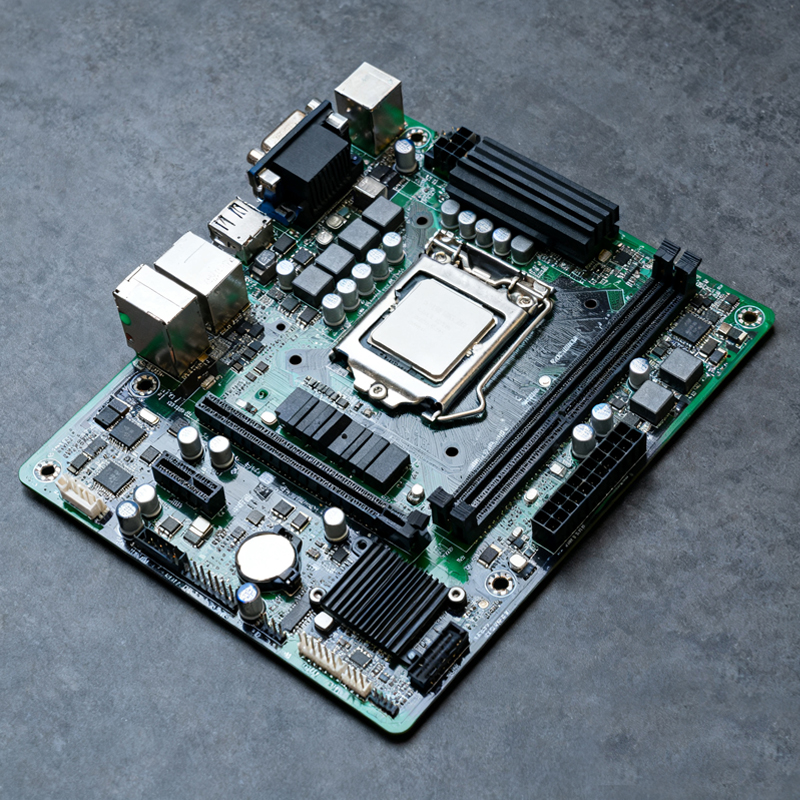

If you’ve ever looked at a computer motherboard—whether it’s for a desktop or a gaming PC—you’ll notice it’s a big, stiff board. Unlike the tiny flexible PCBs in phones, motherboards rely entirely on rigid PCBs. The reason boils down to what a motherboard does: it’s the “central hub” connecting every key part (CPU, RAM, graphics card). It needs to be stable above all else. Let’s break down why rigid PCBs are non-negotiable here, and exactly where that stability comes from—no tech jargon, just straight talk.

Motherboards have jobs that flexible PCBs can’t handle. Here are the 3 biggest reasons they stick with rigid designs:

A motherboard isn’t just circuits—it’s loaded with big, heavy parts:

- The CPU socket (holds the processor, often made of thick metal).

- RAM slots (for memory sticks, which clip into sturdy plastic/metal connectors).

- PCIe slots (for graphics cards or SSDs—some graphics cards weigh over 2 pounds!).

Flexible PCBs would bend or sag under this weight—imagine putting a heavy book on a sheet of paper. Rigid PCBs (usually made of FR-4, a tough fiberglass material) stay flat and strong, even with all these parts attached. No bending, no wiggling—critical for keeping components connected.

Computers use a lot of power: a gaming motherboard can pull 500+ watts when running a top-tier CPU and graphics card. All that power generates heat, and flexible PCBs can’t handle this well—their thin, bendable materials can melt or warp at high temperatures.

Rigid PCBs solve this in two ways:

- The FR-4 substrate is heat-resistant—it stays stable even when the CPU hits 80-90°C.

- Rigid PCBs can fit thicker copper layers (for carrying power) and heat sinks (to cool parts like the voltage regulator). Flexible PCBs are too thin for these upgrades.

Most people upgrade their computers over time—adding more RAM, swapping a graphics card, or installing an SSD. Rigid PCBs have fixed, sturdy slots/connectors that make this easy:

- You can push a RAM stick into a rigid slot and hear a “click”—it stays locked in.

- A graphics card slides into a PCIe slot and screws into the case—no risk of the slot bending.

Flexible PCBs would flex when you push or screw in parts, making installation messy (or impossible). Rigid designs keep everything in place, even when you’re swapping components.

“Stability” isn’t just a buzzword—it’s built into the rigid PCB’s design. Here’s the breakdown:

The core of a rigid PCB is the FR-4 substrate—a thick (usually 1.6-2mm) layer of fiberglass mixed with resin. It’s stiff enough that you can’t bend it with your hands, even if you push hard. This stiffness means:

- Components don’t shift when the computer vibrates (like from a fan).

- The PCB doesn’t warp over time (flexible PCBs can stretch or crease with use).

For example: If your desktop is on a wobbly desk, a rigid motherboard stays flat—so the CPU and RAM never lose contact. A flexible PCB would bounce around, causing crashes or glitches.

Motherboards need to send power evenly to every component—if the CPU gets a unstable power supply, the computer crashes. Rigid PCBs use thicker copper lines (0.03-0.05mm thick) than flexible PCBs (usually 0.01-0.02mm). Thicker copper:

- Carries more power without overheating.

- Doesn’t crack or wear out from constant power flow (thin copper in flexible PCBs can break over time).

This is why gaming motherboards (which need more power) often use “8-layer PCBs”—extra copper layers for even more stable power delivery.

Every slot on a motherboard (RAM, PCIe, CPU) is soldered directly to the rigid PCB with strong, thick solder joints. These joints don’t move, so:

- The RAM stick stays connected even if you bump the case.

- The graphics card doesn’t lose signal when the fan spins fast.

Flexible PCBs have weaker solder joints (since the board bends) that can crack. Rigid PCBs’ fixed joints last for years—even with repeated component swaps.

As mentioned earlier, FR-4 can handle high heat. But rigid PCBs go further: they can have heat sinks glued directly to the board (like on the voltage regulator). These heat sinks pull heat away from critical parts, keeping the motherboard cool and stable. Flexible PCBs can’t hold heat sinks—they’d peel off when the board bends.

A motherboard’s job is to be the “backbone” of your computer—something that never fails, even under heavy use. Flexible PCBs are great for small, bendy devices like phones, but they can’t handle the weight, power, or heat of a motherboard. Rigid PCBs’ stiffness, heat resistance, and sturdy connections are exactly what make your computer run smoothly—whether you’re browsing the web or gaming for hours.

related link: