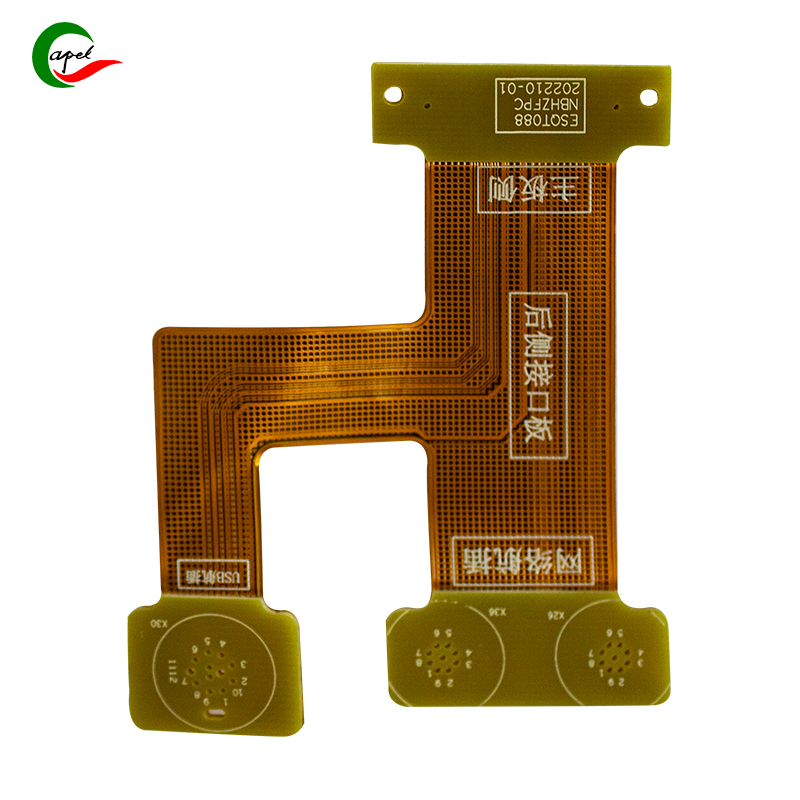

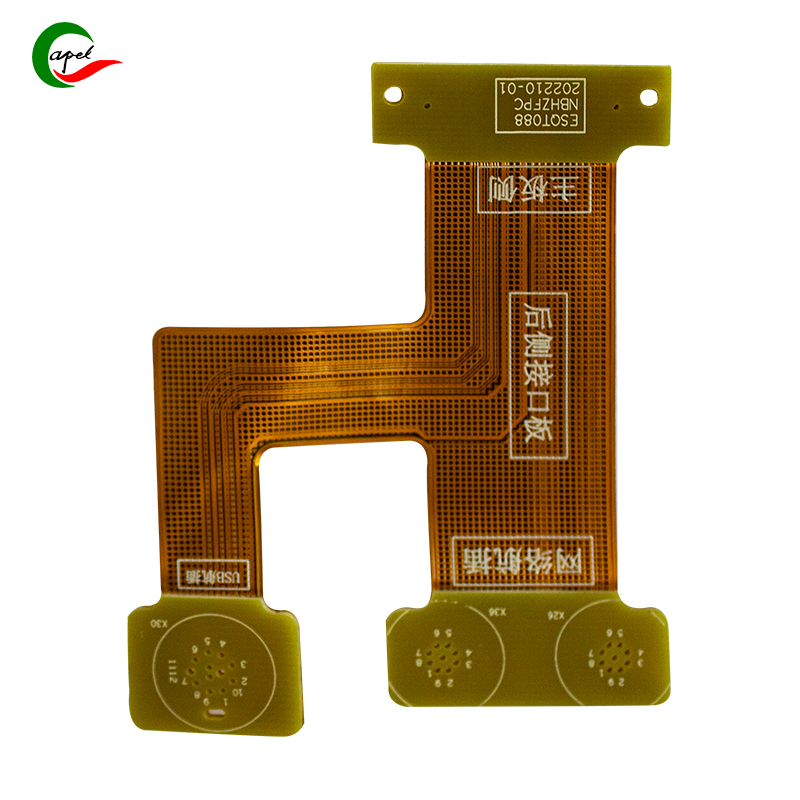

If you’ve ever taken apart an old phone (or seen a teardown video), you might notice those thin, bendable circuit boards—those are flexible PCBs. Phones rely on them way more than rigid PCBs, and it all comes down to one big thing: space. Let’s break down why they’re a must for phones, and just how much room they free up—no tech jargon, just real talk.

Phones are tiny—you want them slim enough to fit in your pocket, but they still need to hold a screen, battery, camera, and more. Flexible PCBs solve problems rigid PCBs can’t, and here’s how:

Rigid PCBs are stiff—they can only sit flat. But phones have curved edges, batteries that take up most of the internal space, and small gaps between components. Flexible PCBs fold or twist to fit those tight spots.

-

Example: The PCB connecting your phone’s screen to its main board. A rigid PCB would force the screen to sit flat against the battery (making the phone thicker), but a flexible PCB bends around the battery’s edge. This lets the screen sit closer to the phone’s front, keeping the whole device slim.

Before flexible PCBs, phones used tiny wires to connect parts like the camera, speaker, and charging port to the main board. Wires are thin, but they need connectors to attach to PCBs—and those connectors take up space. Flexible PCBs act as both “wire” and “connector” in one.

Flexible PCBs are usually just 0.1–0.3mm thick—thinner than a sheet of paper. Rigid PCBs, by contrast, are at least 0.8mm thick (and often thicker with components). In a phone where every 0.1mm of thickness matters, this difference adds up.

-

Example: Foldable phones. A foldable phone’s inner screen needs a PCB that bends every time you open it. A rigid PCB would be too thick and stiff to fold, but a thin flexible PCB bends 180 degrees without breaking—making foldable designs possible.

Saying “they save space” is vague—let’s get specific with numbers that matter for phones:

A typical phone uses 3–5 flexible PCBs (for screen, camera, charging port, etc.). If you replaced those with rigid PCBs and wires, you’d need extra space for:

-

Rigid PCB thickness (0.8mm vs. 0.1mm for flexible).

-

Wire connectors (each takes up about 2–3mm of space).

Total, this adds up to 15–30% more space used inside the phone. For a phone with a 15cm² internal circuit area (about the size of a credit card), that’s 2.25–4.5cm² saved—enough room for a bigger battery (like adding 50–100mAh, which extends battery life by 30–60 minutes).

Rigid PCBs need empty space around them to avoid touching other parts (like the battery or speaker). Flexible PCBs bend into those gaps, so no space goes to waste. For example:

-

A rigid PCB for a phone’s charging port needs a 1mm gap around it to fit. A flexible PCB bends around the battery, so it uses that 1mm gap instead of leaving it empty. Over 3–4 PCBs, this saves 3–4mm of total phone thickness—enough to take a phone from 8mm thick to 4–5mm (the difference between a bulky and slim design).

Foldable phones are the best example. A foldable phone’s main PCB is split into two rigid parts (for the top and bottom screens) connected by a flexible PCB. If you used a single rigid PCB, the phone would be twice as thick when folded (since the rigid board can’t bend). The flexible PCB lets the phone fold flat, saving 50% of the thickness when closed.

Phones wouldn’t be as slim, light, or functional without flexible PCBs. They don’t just save space—they let designers make phones with bigger batteries, foldable screens, and more features, all while keeping them pocket-friendly. Next time you use your phone, remember: those tiny bendable PCBs are why it fits in your pocket instead of your bag.

related link: