Date: 2025-10-08

Alright, pull up a chair. You want to know if water will kill your flex PCB? The short answer: hell yes, it will. But let me tell you why - and more importantly, why most of your gadgets survive anyway.

I've been designing these bendy little boards for fifteen years. Seen 'em in everything from million-dollar medical gear to cheap fitness trackers that die after two months. And I can spot a water-damaged board from across the lab.

Picture this: you've got these hair-thin copper traces carrying data and power. Water bridges two traces that shouldn't touch? Boom - instant short circuit. It's like dropping a wrench across car battery terminals.

But here's what they don't tell you in the spec sheets: it's not the water itself that's the problem - it's the crap IN the water. Your sweat? That's basically saltwater. Tap water? Full of minerals. Even distilled water becomes conductive once it starts dissolving the board's own chemistry.

I remember this one project - smart running earbuds. We kept getting returns with the same failure: audio cutting in and out. Took us weeks to figure out it was sweat slowly migrating through what we thought was a good seal, corroding one specific data line on the flex circuit. The fix? Moving that trace away from the edge and adding a better conformal coating. Cost us about three cents per unit.

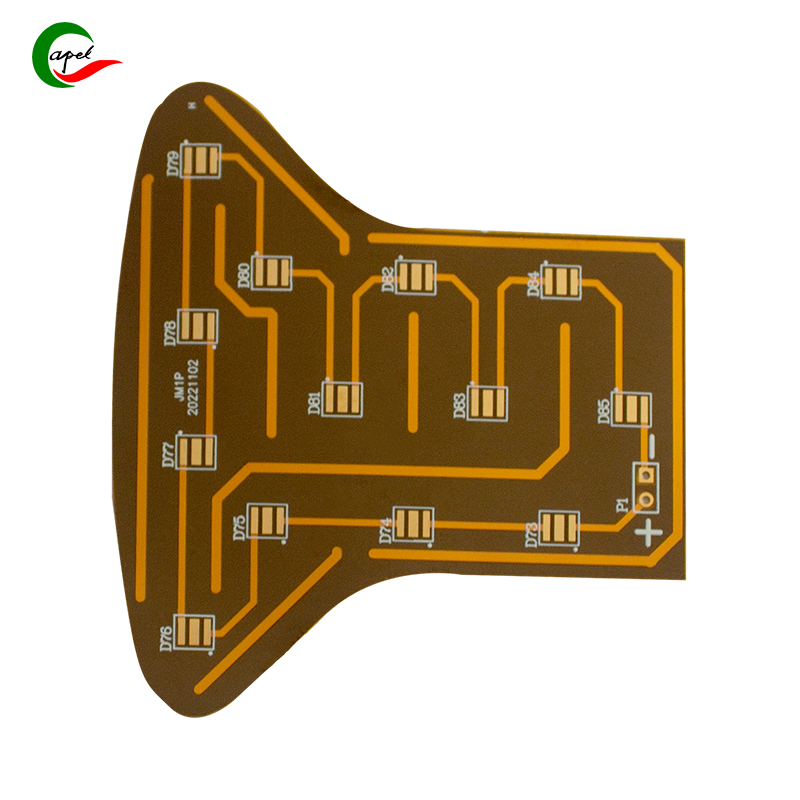

The Bare Minimum: Solder Mask

That colored coating on the board? That's the solder mask. It's like a cheap raincoat - fine for a light drizzle but useless in a downpour. If your device relies solely on this, don't take it anywhere near water.

The Real Protection: Conformal Coating

Now we're talking. This is a thin, transparent coating we spray over the entire board. It's like dipping the whole thing in liquid armor. The good stuff (we usually use silicone or acrylic) can handle serious moisture.

Pro tip: Look for the slightly glossy, uniform finish under a microscope. If you see thin spots or bubbles, that's where water will get in. I've rejected entire production runs over coating defects that most people would never notice.

The Nuclear Option: Potting

For devices that absolutely cannot fail - think automotive sensors or industrial controls - we use potting. This is where we literally encase the entire board in a solid block of epoxy resin. It's bulletproof, but also makes repairs impossible. It's the engineering equivalent of "if it breaks, throw it away."

You can always tell how a flex PCB died by looking at the damage:

Instant death: Burnt spots, melted components, that distinctive electronics-fire smell. Usually from a direct short circuit.

Slow death: Green corrosion creeping along the copper traces, white residue from mineral deposits. This is what sweat damage looks like after a few months.

The silent killer: Electrochemical migration - where metal ions actually grow between traces like tiny silver trees, creating permanent shorts. This one's particularly nasty because it happens slowly and is irreversible.

First, don't be an idiot and try to turn it on "to see if it works." Here's what we do in the lab:

Power off immediately - If the battery's removable, take it out

Disassemble as much as you're comfortable with - Get to the actual board

Flush with 99% isopropyl alcohol - This displaces water and evaporates clean

Air dry for at least 48 hours - No, rice doesn't work better than just leaving it out

Inspect for corrosion - Look for that tell-tale green gunk on the copper

The brutal truth? If there's visible corrosion, the board is probably toast. You can try cleaning it with a fiberglass pen, but you're likely just postponing the inevitable.

Look, flex PCBs and water mix like oil and water - they don't. But with proper protection, they can survive the real world. Your job is to know your device's limits. That "water resistant" smartwatch? It can handle sweat, not swimming. Those wireless earbuds? Maybe rain, but not a downpour.

And if you're designing these things? Don't cheap out on the coating. That extra few cents per unit is way cheaper than warranty returns and pissed-off customers.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..