When building devices with moving parts (like foldable phones) or tight spaces (like wireless earbuds), wiring—those tiny wires that connect PCBs to components—can be a hassle. They take up space, break easily, and add extra steps to assembly. But rigid-flex PCBs, which combine flexible and rigid sections, claim to simplify this. The question is: Do they actually save wiring? And if so, how much? Let’s break this down with real examples and plain language—no confusing jargon.

The short answer is yes—rigid-flex PCBs save wiring by turning external wires into built-in flexible circuits. Here’s how it works:

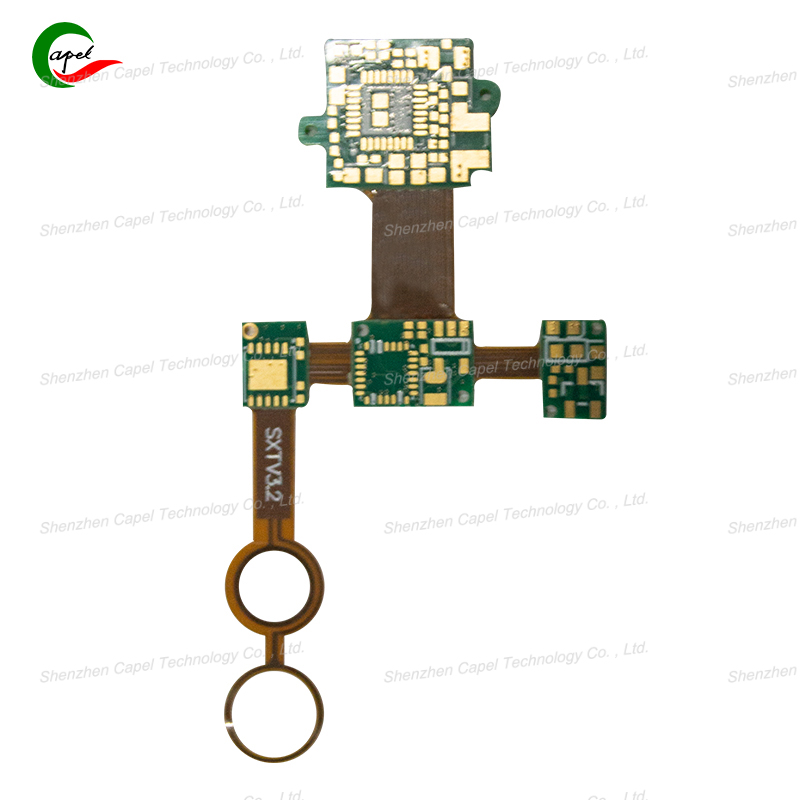

Most devices with multiple PCBs (e.g., a foldable phone has a screen PCB, a battery PCB, and a main PCB) use thin wires to connect them. Rigid-flex PCBs replace these wires with their flexible sections.

-

Example: A foldable phone using separate rigid PCBs needs 4–6 thin wires to link the screen PCB to the main PCB (for power and data). A rigid-flex PCB integrates the screen’s rigid section, the main board’s rigid section, and a flexible “bridge” between them—no wires needed.

-

Math: For a mid-size device (like a wireless earbud case), this cuts 3–5 wires per device. For larger devices (like industrial robots), it can eliminate 10–15 wires.

Some components (like a laptop’s trackpad or a smartwatch’s heart rate sensor) use short wires to connect to the main PCB. Rigid-flex PCBs can extend their flexible sections directly to these components, replacing the wires.

-

Example: A laptop’s trackpad usually uses 2 thin wires to connect to the main board. A rigid-flex PCB’s flexible section can reach the trackpad directly—no wires, just a seamless circuit.

-

Bonus: These wires often need plastic clips to hold them in place (to avoid tangles). Rigid-flex PCBs eliminate the clips too—saving even more parts.

To understand why saving wiring matters, you first need to know the issues with traditional wires. Rigid-flex PCBs don’t just “save wires”—they solve the headaches wires cause:

Wires are thin, but they need extra space to bend and route around components. In tiny devices (like wireless earbuds or smart rings), this space is precious.

-

Example: A wireless earbud has only 1–2 cubic centimeters of internal space. The 2 wires connecting its speaker to the battery take up ~15% of that space. A rigid-flex PCB’s built-in circuit replaces those wires, freeing up space for a bigger battery (extending playtime by 1–2 hours).

Wires are fragile—they can snap if bent too much (like a foldable phone’s hinge wires) or pulled (like a laptop’s trackpad wires). Rigid-flex PCBs’ flexible circuits are made of polyimide and thin copper, which can bend 10,000+ times without breaking.

-

Example: A foldable phone’s wire connections between the screen and main board often fail after 1–2 years of use. A rigid-flex PCB’s flexible section can last 5+ years—cutting repair rates by 60–70%.

Installing wires means: 1) stripping the wire ends, 2) soldering them to the PCB/component, 3) securing them with clips. Rigid-flex PCBs skip all this—you just attach the component directly to the flexible section.

-

Math: Assembling a device with 5 wires takes ~2 minutes of wiring work. A rigid-flex version takes 30 seconds—saving 1.5 minutes per device. For a factory making 1,000 devices a day, that’s 25 hours of labor saved weekly.

Rigid-flex PCBs don’t save wiring in every device—they shine in specific cases where wires are most problematic:

Devices that bend or rotate (like foldable phones, laptops, or robotic arms) rely on wires to connect moving parts. These wires are under constant stress, so rigid-flex’s built-in circuits are a perfect replacement.

-

Example: A foldable tablet’s hinge uses 4 wires to send screen data. A rigid-flex PCB replaces those wires with a flexible section that bends with the hinge—no more broken wires.

In devices where space is measured in millimeters, even a single wire takes up valuable room. Rigid-flex PCBs’ built-in circuits fit into tight spots wires can’t.

-

Example: A skin-mounted medical sensor (the size of a dime) can’t fit the 2 wires needed to connect its sensor to the battery. A rigid-flex PCB’s flexible section links them directly—no wires, just a thin, unnoticeable circuit.

Machines with 5+ components (like a car’s dashboard or a factory’s sensor array) use dozens of wires. Rigid-flex PCBs can integrate all those connections into one board, cutting wire counts drastically.

-

Example: A car’s dashboard uses 8–10 wires to connect the speedometer, radio, and climate control to the main PCB. A rigid-flex PCB replaces those wires with built-in circuits—reducing clutter and failure risks.

Rigid-flex PCBs aren’t a magic fix for all wiring. They won’t save much (or any) wiring in these scenarios:

Devices with no moving parts and only 1–2 PCBs don’t use many wires (usually 1–2). Rigid-flex PCBs would replace those wires, but the cost savings from fewer wires wouldn’t offset the higher cost of the rigid-flex PCB.

If components are far apart (e.g., a desktop PC’s monitor and tower, or a refrigerator’s door and main body), wires are still cheaper and easier than a super-long rigid-flex PCB. Rigid-flex’s flexible sections are best for short distances (under 1 foot).

Rigid-flex PCBs don’t just cut down on the number of wires in a device—they eliminate the space, durability, and assembly problems wires cause. For devices with moving parts, tight spaces, or many components, they’re a game-changer. For simple, rigid devices? Not so much. The key is to ask: Do wires cause problems in my device? If yes, rigid-flex will save you more than just wiring—it’ll save time, money, and frustration in the long run.

related link: