Date: 2025-07-10

Discover the ultimate guide to 4-layer flexible PCB design with expert tips from Kaboer’s 16 years of experience. Explore the importance of 4-layer flex PCBs in modern electronics, best practices for designing and optimizing signal integrity, innovative solutions to overcome design challenges, and future trends in flex PCB design. Learn how Kaboer’s expertise and capabilities can help you stay ahead of the rapidly evolving field of flexible PCB design.

Kaboer has been a leader in flexible PCB design for 16 years, providing innovative solutions to meet the ever-changing needs of modern electronics. Kaboer attaches great importance to research and development and continues to push the boundaries of flexible PCB technology to provide customers with high-quality, reliable and cutting-edge solutions.

In today’s fast-paced, ever-changing electronics industry, the demand for smaller, lighter, and more flexible electronic devices has never been higher. 4-layer flexible PCB design plays a vital role in meeting these needs, providing compact and versatile solutions for a variety of applications such as smart sweeping robots, wearable devices, medical equipment, and more.

A 4-layer flex PCB consists of four layers of conductive material separated by insulating layers, all of which are designed to be flexible. This design adds functionality and performance into a smaller form factor, making it ideal for applications where space is limited and flexibility is critical.

Using a 4-layer flexible PCB has many advantages, including increased design flexibility, improved signal integrity, reduced electromagnetic interference and enhanced thermal performance. These advantages make 4-layer flexible PCB an ideal choice for various electronic products.

When designing a 4-layer flexible PCB, factors such as signal integrity, thermal management, material selection, and manufacturing processes must be considered. By carefully considering these factors, designers can ensure optimal performance and reliability of their flexible PCB designs.

To optimize signal integrity and minimize interference in a 4-layer flex PCB design, designers should pay close attention to signal routing, impedance control, and electromagnetic compatibility. By following best practices in these areas, designers can ensure reliable operation of their flexible PCB designs.

Choosing the right materials is critical for 4-layer flexible PCB design. Factors such as flexibility, thermal performance and dielectric properties must be carefully considered to ensure the desired functionality and reliability of the final product.

In high-speed and high-frequency applications, such as those in smart sweeping robots, designers must pay special attention to impedance matching, signal propagation, and crosstalk. By addressing these design considerations, designers can achieve optimal performance in 4-layer flexible PCB designs.

Designing a 4-layer flexible PCB board presents several challenges, including signal integrity issues, thermal management, material selection and manufacturing complexity. Addressing these challenges is critical to ensuring the successful implementation of a 4-layer flexible PCB design.

Kaboer develops innovative solutions to overcome the challenges associated with 4-layer flexible PCB design. Through advanced research and development, Kaboer introduces cutting-edge technologies and manufacturing processes to solve challenges in signal integrity, thermal management and material selection.

Kaboer has a proven track record of delivering successful 4-layer flexible PCB designs for a variety of applications, including smart sweeping robots. By highlighting these case studies, Kaboer demonstrates its expertise and ability to meet clients’ unique design requirements.

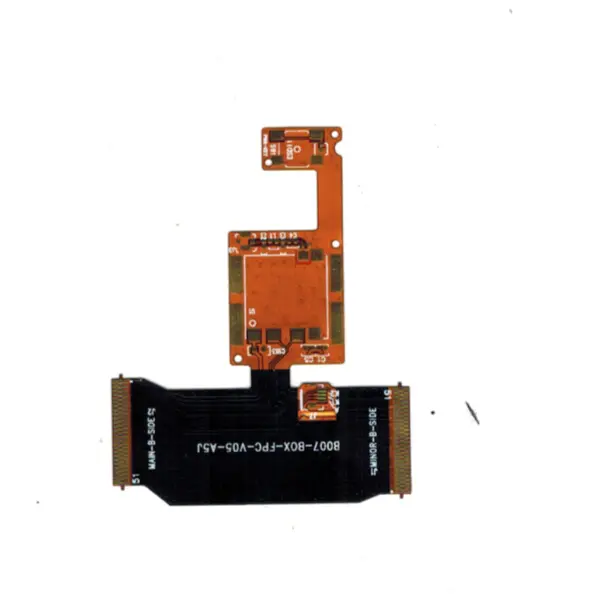

Product type: 4-layer FPC PCB/multilayer board

Application areas: Intelligent sweeping robot

Line width and line spacing: 0.1mm / 0.1mm

Plate thickness: 0.2mm

Minimum hole diameter: 0.2mm

Copper thickness: 12um

Stiffness: steel plate, FR4

Surface treatment: immersion gold

Flame retardant: 94V0

Resistance welding color: black

As technology continues to evolve, emerging trends such as 5G connectivity, the Internet of Things (IoT), and artificial intelligence (AI) are driving new requirements for flexible PCB design. Kaboer is at the forefront of these trends, leveraging its expertise to develop innovative solutions to meet the ever-changing needs of the electronics industry.

Kaboer’s extensive experience and forward-thinking approach allows the company to anticipate and adapt to future trends in 4-layer flexible PCB design. By staying ahead of the curve, Kaboer is well-prepared to address the challenges and opportunities presented by emerging technologies.

To stay ahead of the curve in the rapidly evolving field of flexible PCB design, it’s critical to partner with an experienced and innovative PCB design company like Kaboer. By leveraging Kaboer’s expertise and capabilities, customers can ensure their 4-layer flexible PCB designs are optimized for performance, reliability and manufacturability.

Kaboer’s 16 years of experience in 4-layer flexible PCB design makes the company a trusted and reliable partner for customers looking for innovative and high-quality solutions. Through a combination of expertise, advanced technology and a customer-centric approach, Kaboer continues to lead the way in flexible PCB design.

Working with an experienced, innovative PCB design company like Kaboer is critical to success in 4-layer flex PCB design. Kaboer’s commitment to excellence, continuous innovation and customer satisfaction makes it the ideal partner for customers seeking cutting-edge flexible PCB solutions.

For customers seeking high quality, reliable and innovative 4-layer flexible PCB designs, Kaboer offers comprehensive customization services to meet their unique needs. By partnering with Kaboer, customers gain access to the expertise and capabilities they need to implement flexible PCB designs.

In summary, as electronic products become smaller, lighter, and more versatile, the demand for 4-layer flexible PCB designs continues to grow. Kaboer’s 16 years of experience, coupled with a commitment to innovation and excellence, make it the ideal partner for customers seeking high-quality, reliable 4-layer flex PCB solutions. By leveraging Kaboer’s expertise and capabilities, customers can ensure their flexible PCB designs are optimized for performance, reliability and manufacturability to succeed in the rapidly evolving electronics industry.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..