|

FLEXIBLE PCBs PRODUCTION PROCESS CAPEL Advanced FPC, what makes it different? |

||||

| Raw Material | Branded raw material (Dupont, Panasonic, Shengyi, TAIFLEX, ARLON, 3M, etc.); Halogen-free material; Large size & stable performance material; |

|||

| Drilling | Numerical control drilling; Laser micro drilling; |

|||

| PTH | Copper plating; Nanometer graphene coating; |

|||

| Electroplating | Gantry style electroplate; VCP continuous vertical plating; |

|||

| Trace | LDI laser exposure process; | |||

| Etching | Vacuum etching | |||

| Lamination | Automatic machine film Alignment | |||

| Testing Method | 4-wire flying probe testing; 4-wire in-circuit testing |

|||

| Surface Finishes | Immersion Gold; OSP; Electroless Nickel/Electroless Palladium/Immersion Gold; |

|||

| Assembly | Jig Assembly; Automatic reinforcement Assembly |

|||

| Printing | High-resolution Inkjet Printing | |||

| Profile | High Precision Die Punching; Laser Cut |

|||

FPC Production Process

Shenzhen Capel Technology Co., Ltd.

|

RIGID-FLEX PCBs PRODUCTION PROCESS CAPEL Advanced Rigid-Flex PCB, what makes it different? |

||||

| Raw Material | Branded raw material (Dupont, Panasonic, Shengyi, TAIFLEX, ARLON, 3M, etc.); Halogen-free material; Large size & stable performance material; |

|||

| Drilling | Numerical control drilling; Laser micro drilling; |

|||

| PTH | Copper plating; Nanometer graphene coating; |

|||

| Electroplating | Gantry style electroplate; VCP continuous vertical plating; |

|||

| Trace | LDI laser exposure process; | |||

| Etching | Vacuum etching | |||

| Lamination | Automatic machine film Alignment | |||

| Testing Method | 4-wire flying probe testing; 4-wire in-circuit testing |

|||

| Surface Finishes | Immersion Gold; OSP; Electroless Nickel/Electroless Palladium/Immersion Gold; |

|||

| Assembly | Jig Assembly; Automatic reinforcement Assembly |

|||

| Printing | High-resolution Inkjet Printing | |||

| Profile | High Precision Die Punching; Laser Cut |

|||

Rigid-Flex PCBs Production Process

Shenzhen Capel Technology Co., Ltd.

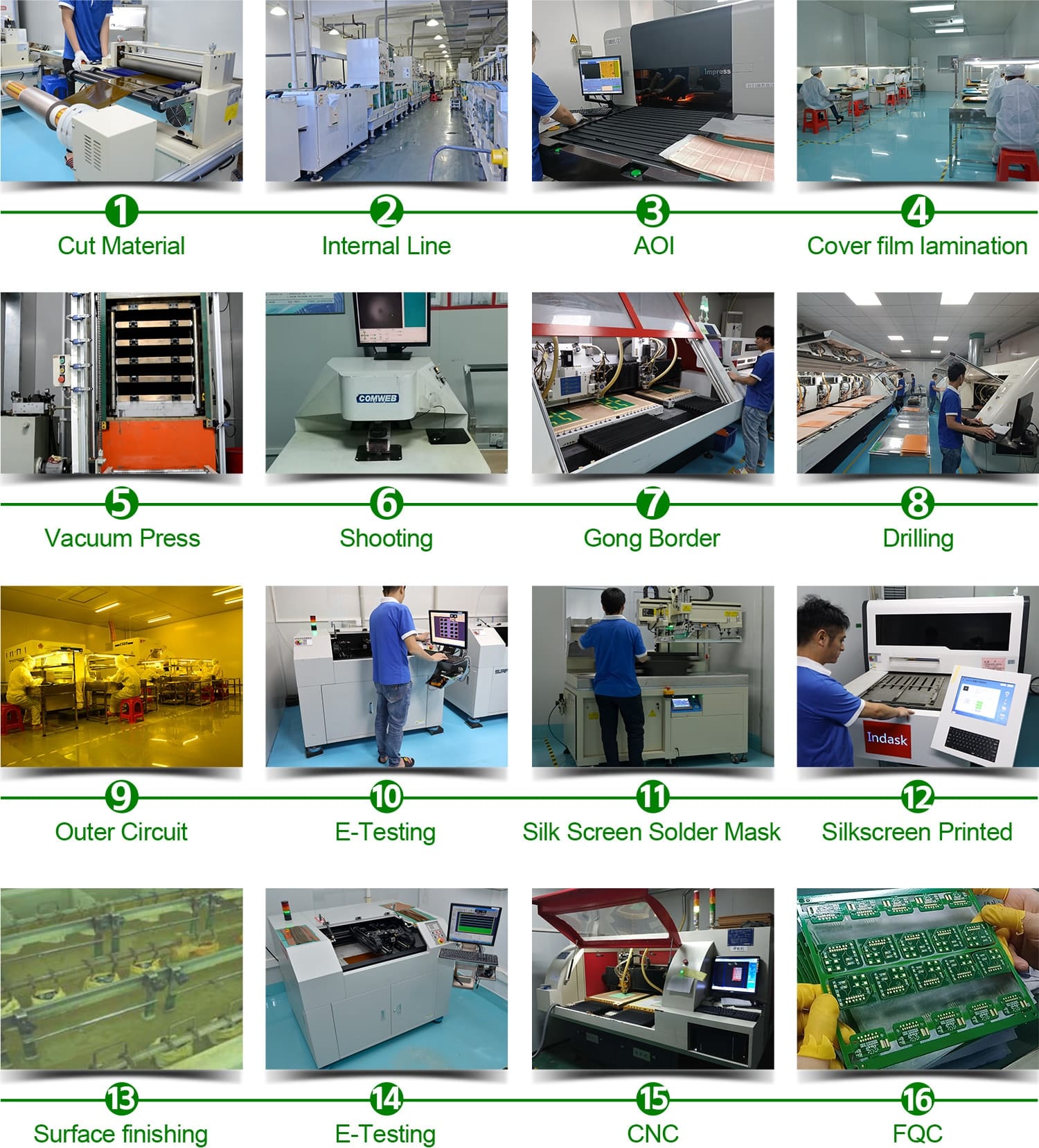

| PCB PRODUCTION PROCESS

CAPEL Premium PCB, what makes it different? |

|||||||

| Raw Material | High performance FR4; Halogen-free FR4; Large size & stable performance material; |

||||||

| Ink | High performance ink; Halogen-free ink; |

||||||

| Drilling | Numerical control drilling; Laser micro drilling; |

||||||

| PTH | Copper plating; Nanometer graphene coating; |

||||||

| Electroplating | Gantry style electroplate; VCP continuous vertical plating; |

||||||

| Trace | Parallel light exposure process; LDI laser exposure process; |

||||||

| Etching | Chemical etching; Laser etching; Vacuum etching; |

||||||

| Stack-up | Hot oil press machine (large-scale); | ||||||

| Soldermask | Exposure developing process; Silkscreen printing process; Electrostatic spraying process; Vacuum printing process; Resin/ink plug hole process; |

||||||

| Silkscreen | Screen printing process Hd inkjet printing process |

||||||

| PCB Profile | High precision numerical control machine tab-routing process; | ||||||

PCB Production Process

Shenzhen Capel Technology Co., Ltd.

| PCBA PRODUCTION PROCESS

CAPEL High Quality pcba, what makes it different? |

||||||

| High Quality | A-Grade Raw Materials Advanced Siemens PCBA Machines Operators with 15 Years Experience |

|||||

| Quick Turnaround | Online Quote in Minutes Smart Production Scheduling System Expedited DHL Delivery within 2-4 Days |

|||||

| Low Cost | Highly Automated, Lower Cost FREE Stencil and Set-up & Tooling Incremental Deductions with More Orders |

|||||

| Dedicated Customer Service | 7*24 Online Customer Service Professional Technical Support High-Performance Supply Chain |

|||||

PCBA Production Process

Shenzhen Capel Technology Co., Ltd.