As IoT, wearables, and miniaturized electronics dominate 2025, rigid-flex PCBs are no longer "niche"—they’re becoming a mainstream solution. For engineers and purchasing teams, understanding their latest trends isn’t just helpful; it’s critical to staying competitive. Below are the non-negotiable insights to guide your decisions.

2025 will see a shift from traditional polyimide (PI) to high-performance flexible substrates that balance thinness and durability. For example, new PI variants with 30% higher bend cycles (up to 100,000 folds without cracking) are ideal for foldable IoT sensors—engineers can now design devices that twist or collapse without damaging circuits.

Sustainability is another driver. Suppliers are rolling out recyclable rigid sections (using plant-based epoxy resins) and lead-free solders that meet EU’s 2025 eco-regulations. Purchasing teams need to prioritize suppliers with these certifications—delays in compliance could derail product launches.

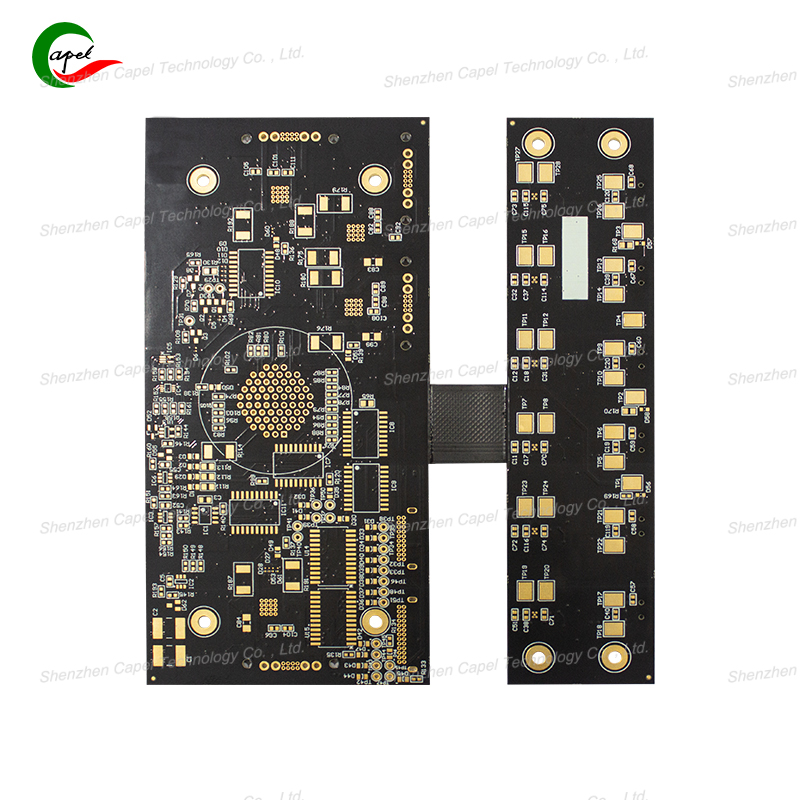

IoT devices in 2025 are shrinking (think thumbnail-sized health monitors), so rigid-flex PCBs are adopting microvia technology (holes as small as 0.1mm) and stacked flexible layers. Engineers can now fit 50% more components (like microchips and antennas) on a single board by folding flexible sections over rigid cores—no more wasting space on connectors.

Purchasing note: Microvia manufacturing requires precision equipment, so partner with suppliers who have ISO 13485 (medical-grade) or IPC 6012DS (flexible PCB) certifications. Cheaper alternatives often fail quality tests for small-scale designs.

Rigid-flex PCBs are no longer just "circuit carriers"—they’re becoming integrated systems. In 2025, manufacturers will embed tiny sensors (for temperature, pressure) and flexible antennas directly into flexible layers. For example, a smartwatch PCB can now have a built-in heart-rate sensor on its flexible wristband section, cutting component costs by 20%.

Engineers should collaborate with PCB suppliers early—embedding components requires custom design tweaks (e.g., adjusting layer thickness for sensor accuracy). Purchasing teams can negotiate bulk discounts by combining PCB orders with sensor procurement from the same supplier.

Post-2024 chip shortages taught the industry a lesson: over-reliance on a single region is risky. In 2025, rigid-flex PCB production will regionalize—more factories in North America and Southeast Asia will serve local markets (e.g., U.S. automotive IoT firms partnering with Mexican suppliers).

This benefits both roles: Engineers get faster access to prototypes (lead times down to 7–10 days, vs. 4–6 weeks for overseas orders), while purchasing teams avoid shipping delays and import tariffs. Pro tip: Ask suppliers for "just-in-time" (JIT) delivery plans—critical for high-volume products like smart home devices.

Rigid-flex PCBs still cost 30–50% more than traditional PCBs, but 2025 brings cost-saving hacks. For low-volume projects (e.g., medical devices), engineers can use semi-flexible designs (partial flexible layers instead of full flexibility) to cut costs by 25%. For high-volume orders (e.g., 100,000+ units), purchasing teams can lock in long-term contracts with suppliers to lower per-unit prices by 15–20%.

Key rule: Don’t sacrifice quality for cost. A cheap rigid-flex PCB with poor adhesive (common in uncertified suppliers) will fail in 6 months—costing more in recalls than the initial savings.

For engineers, 2025’s rigid-flex trends mean more design freedom—but also more complexity. Prioritize material testing and early supplier collaboration. For purchasing teams, focus on compliance, regional suppliers, and cost bundling. The goal isn’t just to "use" rigid-flex PCBs—it’s to leverage them to build devices that are smaller, smarter, and more profitable.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.