Date: 2026-02-02

Have you ever wondered why electronics used outdoors, like streetlight controllers or automotive components, keep working reliably despite wind and rain? One key secret is an invisible "clear raincoat" – acrylic PCB conformal coating. It's a special protective layer applied over assembled circuit boards, specifically designed to fend off harsh environments.

In simple terms, acrylic conformal coating is a protective coating primarily made from acrylic resin. It acts like a transparent film, conforming tightly to the PCB and all its components, forming a physical and chemical barrier.

A bare circuit board is vulnerable, facing three main enemies:

Moisture & Condensation: The #1 cause of failure, leading to short circuits, corrosion, and leakage currents.

Dust & Contaminants: Airborne dust, salt spray, or chemical fumes can cause electrical leakage or corrosion.

Mechanical Stress & Accidents: Minor scratches, vibration, or accidental touches during handling or repair.

Conformal coating is applied to isolate the board from these threats, significantly boosting long-term reliability, safety, and service life.

Among various coating materials, acrylic is widely popular for its unique balance. Here’s what defines it:

Excellent Clarity & Hardness: Cures glass-clear, allowing easy visual inspection of components and traces. It's also quite hard, offering good abrasion and scratch resistance.

Superb Moisture Resistance: It forms an excellent barrier against humidity, making it a strong choice for damp environments.

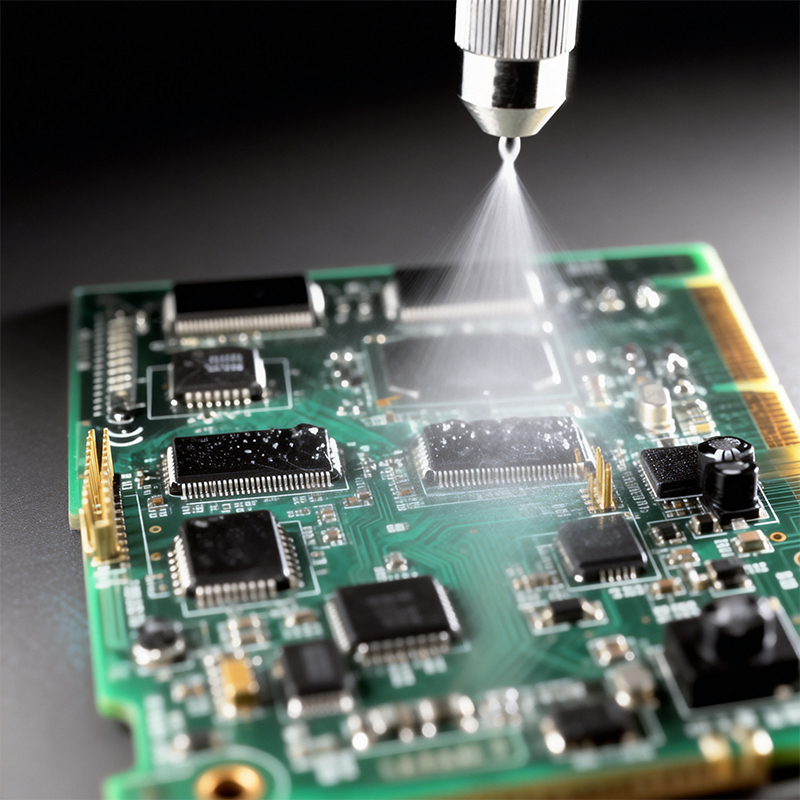

Easy Application: It's typically applied by spraying, brushing, or dipping and cures quickly at room temperature, facilitating production.

Repairability (Key Advantage): This is its most valued trait. For repairs, common solvents (like certain alcohols or thinners) can soften, dissolve, and remove the coating locally, allowing easy replacement of faulty components. The area can be re-coated afterwards. This is crucial for products requiring upgrades or rework.

Good Electrical Insulation: Effectively prevents leakage currents or arcing in high-humidity conditions.

Acrylic coating is ideal for products with relatively stable operating conditions that require moisture protection and visual inspection:

Indoor Industrial Equipment: PLC controllers, motor drives, PCBs inside indoor cabinets.

Consumer Electronics: Control boards for washing machines, air conditioners, and internal circuits where aesthetics matter.

Lighting Industry: LED driver boards, especially where good clarity is needed.

Telecom Equipment: Internal modules of some base stations and networking gear.

Besides acrylic, other common coating materials exist. Knowing them helps you choose best:

| Coating Type | Core Characteristics | It's like... | Best For... |

|---|---|---|---|

| Acrylic (AR) | Clear, hard, easy to repair, great moisture resistance | A clear, rigid raincoat | Most indoor & general industrial environments, products needing rework. |

| Urethane (UR) | Excellent abrasion & chemical/solvent resistance, flexible | Oil-resistant rubber boots | Harsh environments like automotive/marine where oil/fuel contact is possible. |

| Silicone (SR) | Extreme temp. resistance (-50°C to 200°C+), highly flexible | A flexible silicone baking mat | High-heat or wide temp. swing areas (engine bays, high-power lights). |

| Epoxy (ER) | Very hard, high adhesion, good chemical resistance, but brittle | A hard ceramic glaze | Extreme environments with heavy mechanical/chemical stress. Nearly impossible to rework. |

Define the Environment: This is the primary criterion. What will your product face most: moisture, heat, chemicals, or abrasion?

Consider Repair Needs: Will the product need servicing or upgrades during its life? If yes, acrylic is often the first choice.

Mind Application Details:

Masking: Areas like connectors, heatsinks, and test points must be protected with tape.

Thickness: More isn't always better. Too thin offers poor protection; too thick can trap heat or cause stress. A dry film thickness of 1-3 mils (25-75 μm) is typical.

Curing: Ensure proper curing time/conditions as per the datasheet for full performance.

In summary, acrylic conformal coating is like putting a clear, stiff, waterproof "raincoat" on your PCB that can be easily taken off if needed. It strikes the best balance between moisture resistance, ease of use, and reworkability, making it a classic, reliable choice for a vast range of electronics, especially those where future maintenance is a consideration.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..