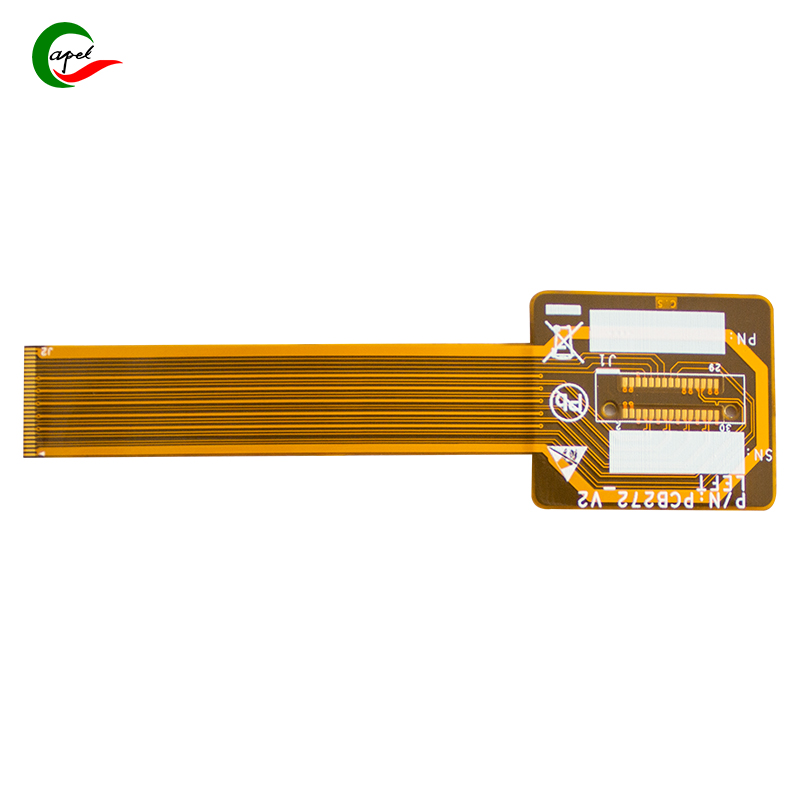

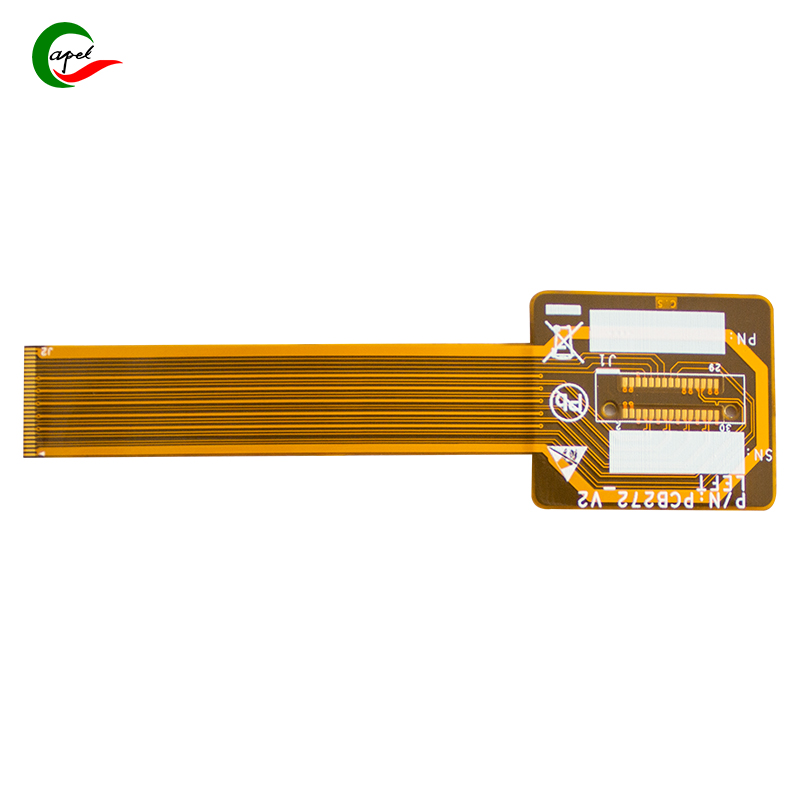

Wearable devices—from smartwatches that monitor heart rates to AR glasses that overlay digital information—are redefining how we interact with technology. These gadgets share a critical trait: they must conform to the human body, blending comfort, durability, and functionality. Rigid PCBs, with their fixed shapes and bulk, fall short here. Enter flexible printed circuits (FPCs), the unsung enablers of wearable innovation. FPCs don’t just fit into tight, curved spaces—they enhance performance, extend battery life, and unlock designs that were once impossible. Let’s dive into why FPCs have become the backbone of the wearable tech revolution.

1. Unmatched Form Factor Flexibility: Conforming to the Body

Wearables live on the body—wrapped around wrists, tucked behind ears, or strapped to limbs. Their circuits must bend, twist, and curve without sacrificing performance. FPCs excel here:

- Thinness that enables comfort: FPCs for wearables are often just 0.05mm–0.1mm thick—thin enough to lie flat under a smartwatch’s casing or within the band itself. Compare that to rigid PCBs, which typically start at 0.2mm and feel bulky against the skin.

- Bendability for dynamic movement: Rolled annealed (RA) copper, the gold standard for wearable FPCs, can withstand 100,000+ flex cycles without cracking. This is critical for devices like fitness trackers, which endure constant wrist movement, or smart rings, which bend with every finger gesture.

- Custom shapes for ergonomics: FPCs are laser-cut into intricate patterns, allowing designers to follow the body’s contours. For example, Oura Ring uses a curved FPC that wraps around the inner circumference of the ring, maximizing sensor contact with the finger while staying invisible to the user.

2. Space Efficiency: Packing More Tech into Tiny Devices

Wearables demand powerful features—heart rate monitors, GPS, biometric sensors—in 巴掌大的 spaces. FPCs solve the "size vs. capability" dilemma:

- 3D routing in tight volumes: Unlike rigid PCBs, which are limited to flat surfaces, FPCs can snake through crevices and wrap around components. In Apple Watch Ultra, FPCs connect the display, battery, and sensor array, fitting into a case that’s just 49mm in diameter.

- Reduced weight for all-day wear: FPCs weigh 30–50% less than equivalent rigid PCBs. For AR glasses (like Meta’s Ray-Ban Stories), this translates to lighter frames that don’t strain the nose or ears during hours of use.

- Integration with flexible batteries: Wearables often use thin, flexible batteries (30μm–100μm thick) to save space. FPCs bond directly to these batteries, eliminating bulky connectors and ensuring efficient power transfer—critical for extending runtime in devices like Fitbit’s Charge series.

3. Durability in Daily Use: Surviving Sweat, Moisture, and Impact

Wearables face harsh conditions: sweat, rain, drops, and constant friction. FPCs are engineered to survive:

- Moisture resistance: Polyimide (PI) substrates, the base of most wearable FPCs, are inherently water-resistant. Combined with conformal coatings (like parylene), they protect against sweat in fitness bands or rain in outdoor trackers. Garmin’s Epix 2, for example, uses FPCs rated IPX8 (waterproof to 100m) for its underwater tracking features.

- Temperature tolerance: From freezing winter runs to hot yoga sessions, wearable FPCs operate reliably between -40°C and 85°C. This stability ensures consistent sensor readings in devices like Samsung Galaxy Watch’s body composition analyzer.

- Impact resilience: FPCs absorb shock better than rigid PCBs, which can crack on impact. In smart helmets (e.g., Forcite’s MK1S), FPCs connecting crash sensors and communication modules withstand the jolts of biking or skiing accidents.

4. Enhanced Signal Integrity: Critical for Biometric Sensors

Wearables rely on tiny sensors to measure heart rate, blood oxygen, and skin conductance—signals that are weak and easily disrupted. FPCs preserve these signals:

- Low-noise designs: FPCs with tight impedance control (±5Ω) minimize signal loss between sensors and microprocessors. This is vital for ECG monitors in smartwatches, where even a small distortion can corrupt heart rhythm data.

- EMI shielding: Copper foil layers on FPCs block electromagnetic interference from nearby components (like the device’s radio or battery). In Withings ScanWatch, this shielding ensures accurate blood oxygen readings despite the watch’s compact layout.

- High-frequency support: Emerging wearables, such as glucose-monitoring patches, use 60GHz+ radar signals. FPCs with liquid crystal polymer (LCP) substrates handle these frequencies with minimal attenuation, enabling non-invasive health tracking.

5. Cost-Effectiveness for High-Volume, Custom Designs

Wearables often require unique designs (e.g., a child’s smartwatch vs. a medical-grade patch), but low production volumes can make rigid PCBs expensive. FPCs offer flexibility without breaking the bank:

- Rapid prototyping: FPCs are easier to modify than rigid PCBs—design changes (like adding a sensor trace) can be implemented in days, accelerating the development of new wearables. Startups like Whoop rely on this to iterate quickly on their fitness bands.

- Scalable manufacturing: Once a design is finalized, FPCs are mass-produced using roll-to-roll processes, lowering per-unit costs. This scalability has made affordable fitness trackers (under $50) accessible to mainstream consumers.

- Reduced assembly steps: FPCs integrate multiple functions (e.g., power, data, and sensor lines) into a single layer, cutting down on the number of connectors and solder joints. This simplifies assembly and reduces failure points in devices like Xiaomi’s Mi Band.

Case Study: How FPCs Enabled the Apple Watch Ultra

The Apple Watch Ultra, designed for extreme athletes, showcases FPCs’ versatility:

- Its 49mm case houses a 2000-nit display, a 36-hour battery, and sensors for GPS, heart rate, and depth. FPCs route signals between these components, wrapping around the battery and under the display to save space.

- The watch’s Action Button and Digital Crown use FPCs with RA copper, ensuring reliable performance after years of intense use.

- LCP-based FPCs in the antenna module enable 4G connectivity even in remote locations, a critical feature for outdoor adventurers.

Future Trends: FPCs Powering Next-Gen Wearables

As wearables evolve, FPCs will push further:

- Stretchable FPCs: Research into elastomeric substrates could enable FPCs that stretch by 30%+—ideal for skin-tight fitness suits or medical wraps.

- Integrated sensors: FPCs with embedded conductive ink sensors may replace bulky discrete components, making wearables even thinner.

- Energy harvesting: FPCs paired with flexible solar cells could power wearables indefinitely, eliminating the need to charge.

Conclusion: FPCs Are the Wearable Revolution’s Foundation

Wearables thrive when they disappear into daily life—when they feel like part of the body, not a gadget. FPCs make this possible, combining flexibility, durability, and performance in a way rigid PCBs never could. From smartwatches to health patches, they’re the reason wearables can monitor our vitals, track our workouts, and keep us connected—all while staying comfortable and out of sight.

For engineers and designers, the message is clear: To innovate in wearables, start with FPCs. They’re not just a component—they’re the key to unlocking the next generation of body-worn technology.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.