Date: 2025-12-19

Assembling circuit boards, commonly referred to as PCB assembly (PCBA), is the transformative process where electronic components are permanently mounted onto printed circuit boards to create functional electronic devices. This intricate manufacturing discipline combines precision engineering, advanced automation, and rigorous quality control—serving as the bridge between circuit design and finished electronic products.

SMT represents the dominant approach in modern electronics manufacturing, where components are mounted directly onto the surface of PCBs.

Key SMT Process Stages:

Solder Paste Application: Precision deposition of solder paste through laser-cut stencils

Component Placement: High-speed automated machines placing components at rates exceeding 25,000 placements per hour

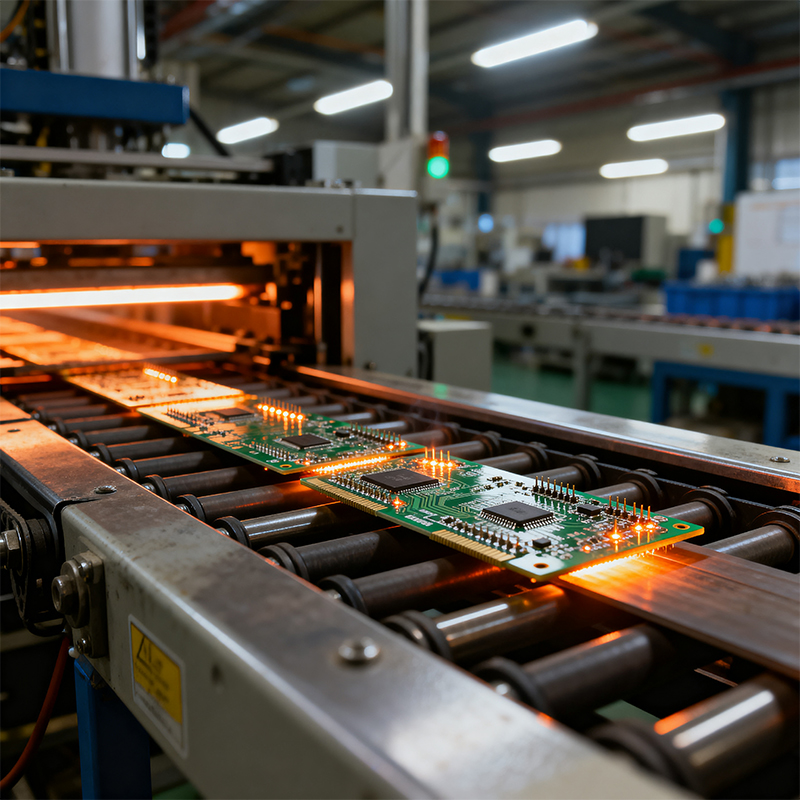

Reflow Soldering: Controlled heating to melt solder and form permanent connections

Cleaning: Removal of flux residues and contaminants

Advantages:

Enables miniaturization with smaller components and higher density

Supports automated, high-volume production

Allows for components on both sides of the PCB

Typically lower production costs at scale

The traditional method where component leads are inserted through drilled holes and soldered to pads on the opposite side.

Key THT Process Stages:

Component Insertion: Manual or automated insertion of leaded components

Wave Soldering: Board passes over a wave of molten solder

Lead Trimming: Cutting excess component leads

Applications:

Components requiring mechanical strength (connectors, transformers)

High-power or high-voltage applications

Prototypes and specialized low-volume products

Most modern boards utilize both SMT and THT approaches, requiring specialized processes:

Sequence Optimization: Determining optimal order of SMT and THT operations

Selective Soldering: Precise soldering of through-hole components on otherwise SMT boards

Process Integration: Managing thermal profiles for multiple soldering operations

Design Review: Manufacturing feasibility analysis of PCB designs

Component Verification: Ensuring all components meet specifications and are available

Stencil Fabrication: Creating solder paste application templates

Program Development: Machine programming for pick-and-place equipment

Stencil Alignment: Precise alignment with PCB solder pads

Printing Process: Controlled deposition of solder paste

Inspection: 2D/3D measurement of paste volume and alignment

Automated Pick-and-Place: High-speed robotic component placement

Vision Systems: Component verification and alignment correction

Tape-and-Reel Feeding: Continuous component supply for production efficiency

Reflow Oven Process: Controlled temperature zones melt solder to form connections

Atmosphere Control: Nitrogen environments for superior solder joint quality

Profile Optimization: Board-specific thermal profiles for different component types

Automated Optical Inspection (AOI): High-resolution camera systems checking for placement accuracy and solder defects

X-Ray Inspection: Internal examination of BGA, QFN, and hidden solder joints

In-Circuit Testing (ICT): Electrical verification of component presence, orientation, and basic functionality

Flying Probe Testing: Flexible electrical testing without custom fixtures

Conformal Coating: Protective layer application for harsh environments

Final Assembly: Installation of connectors, heatsinks, and mechanical components

Functional Testing: Comprehensive validation of complete board functionality

Packaging: Anti-static packaging for shipment

Proactive design optimization to ensure efficient, reliable, and cost-effective assembly:

Component Selection: Standardized parts with reliable supply chains

Placement Considerations: Adequate spacing for automated assembly

Thermal Management: Component placement considering heat dissipation

Test Point Accessibility: Provision for comprehensive testing

Statistical Process Control: Real-time monitoring of production quality metrics

Traceability Systems: Component-level tracking throughout production

Failure Analysis: Systematic investigation of defects to prevent recurrence

Compliance Management: Adherence to industry standards (IPC, ISO, UL)

Component Sourcing: Reliable procurement with counterfeit mitigation

Inventory Management: Balancing availability with carrying costs

Alternate Sourcing: Identifying acceptable component substitutes

Lead Time Management: Realistic production scheduling

Microvia Technology: Laser-drilled vias for ultra-fine interconnections

Sequential Lamination: Multiple lamination cycles for complex routing

Advanced Materials: High-performance substrates for signal integrity

Specialized Handling: Fixtures and processes for flexible substrates

Adhesive Selection: Appropriate bonding materials for flex circuits

Strain Relief: Design considerations for moving applications

Die Attach: Precise placement of bare semiconductor dies

Wire Bonding: Ultrasonic or thermosonic interconnection

Encapsulation: Protective covering of delicate assemblies

Component Handling: Managing ultra-small components (01005, 0201)

Placement Accuracy: Increasing precision requirements

Inspection Limitations: Visual confirmation of microscopic features

Process Sequencing: Optimal order for multiple assembly operations

Thermal Management: Protecting sensitive components during multiple soldering cycles

Rework Difficulties: Accessing components in dense mixed-technology boards

Defect Detection: Identifying increasingly subtle assembly flaws

Process Consistency: Maintaining quality across high-volume production

False Failures: Differentiating true defects from inspection system anomalies

Equipment Obsolescence: Keeping pace with advancing component packaging

Skill Development: Training technicians on new technologies

Process Validation: Establishing reliability for novel assembly approaches

Panelization: Efficient PCB array layouts to maximize material usage

Standardization: Minimizing unique components and processes

Test Strategy: Balancing test coverage with implementation cost

Line Balancing: Optimizing workflow through assembly stations

Changeover Reduction: Minimizing setup time between production runs

Yield Improvement: Reducing scrap and rework through process control

Prototype vs. Production: Different cost structures for various quantities

Tooling Investments: Amortizing capital costs across production volumes

Supply Chain Leverage: Component pricing advantages at scale

Successfully assembling circuit boards requires more than just equipment—it demands integrated expertise across design, procurement, manufacturing, and quality assurance. At Kaboer, we've built our reputation on delivering precisely this comprehensive capability from our advanced manufacturing facility in Shenzhen, China.

State-of-the-Art Manufacturing Infrastructure

Automated SMT lines capable of handling components down to 01005 size

Advanced inspection systems including 3D AOI and high-resolution X-ray

Climate-controlled production environment ensuring process consistency

Complete through-hole capabilities including selective soldering

Engineering-Led Process Optimization

Proactive DFM analysis that identifies potential issues before production

Customized process development for challenging assemblies

Thermal profile optimization for complex mixed-technology boards

Continuous process improvement based on production analytics

Integrated Quality Management

IPC-certified production staff and inspection standards

Full traceability from component receipt to finished assembly

Statistical process control with real-time monitoring

Comprehensive testing options tailored to product requirements

Supply Chain Reliability

Established relationships with component manufacturers and distributors

Rigorous component verification and counterfeit detection

Safety stock management for critical components

Alternate sourcing strategies to mitigate supply disruptions

Flexible Service Models

Prototype assembly with rapid turnaround for design validation

Low-to-medium volume production with quick launch capabilities

High-volume manufacturing with consistent quality at scale

Complete box-build assembly including final product integration

Whether you're developing a novel IoT device, medical instrument, industrial controller, or consumer electronic, assembling circuit boards with precision and reliability is where your concept becomes reality. Kaboer's expertise ensures this transition happens efficiently, economically, and with quality that stands up to real-world use.

Smart Factories: Connected equipment with real-time data exchange

Predictive Maintenance: Anticipating equipment needs before failures occur

Adaptive Processes: Self-adjusting parameters based on real-time conditions

Lead-Free Processes: Continuing evolution of environmentally-friendly solders

Material Efficiency: Reduced waste through process optimization

Energy Conservation: Lower power consumption in assembly operations

Embedded Components: Components within the PCB substrate itself

Additive Electronics: 3D printing of circuits and components

Heterogeneous Integration: Combining disparate technologies in single packages

Assembling circuit boards represents the critical convergence point where electronic designs are translated into physical products. The quality, reliability, and cost-effectiveness of this process directly determine market success in today's competitive electronics industry.

By understanding the full spectrum of assembly technologies, challenges, and best practices—and by partnering with experienced manufacturing specialists like Kaboer—electronics companies can transform innovative concepts into reliable, manufacturable, and successful products. In an industry where technological advancement never pauses, excellence in circuit board assembly remains a fundamental competitive advantage.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..