Date: 2025-12-19

A prototyping board (also known as a prototype PCB, breadboard, or development board) is a foundational tool used to build, test, and validate electronic circuit designs before committing to full-scale production. It serves as the physical platform where engineers and designers integrate components, verify functionality, debug issues, and refine their concepts. Unlike final production PCBs, prototyping boards prioritize flexibility, rapid iteration, and cost-effectiveness for low-volume validation.

Purpose: Ideal for initial concept validation and educational use

Structure: Plastic board with interconnected spring-clip contacts

Advantages: No soldering required; completely reusable; rapid circuit changes

Limitations: Unsuitable for high-frequency or high-current circuits; mechanical instability

Purpose: Intermediate prototyping with semi-permanent connections

Structure: Rigid board with pre-drilled holes on standard grid patterns

Advantages: More reliable than breadboards; supports soldered connections; handles moderate complexity

Common Types: Single-sided, double-sided, and copper-clad variants

Purpose: Structured prototyping with predefined copper tracks

Structure: Perforated board with parallel copper strips running along one side

Advantages: Reduces wiring complexity; suitable for digital and analog circuits

Design Consideration: Requires strategic track cutting to isolate connections

Purpose: High-fidelity prototyping that closely resembles final production boards

Structure: Professionally manufactured boards with custom layouts

Advantages: Validates manufacturability; tests signal integrity and thermal performance; essential for complex designs

Manufacturing Methods: Quick-turn PCB fabrication with reduced lead times (often 24-72 hours)

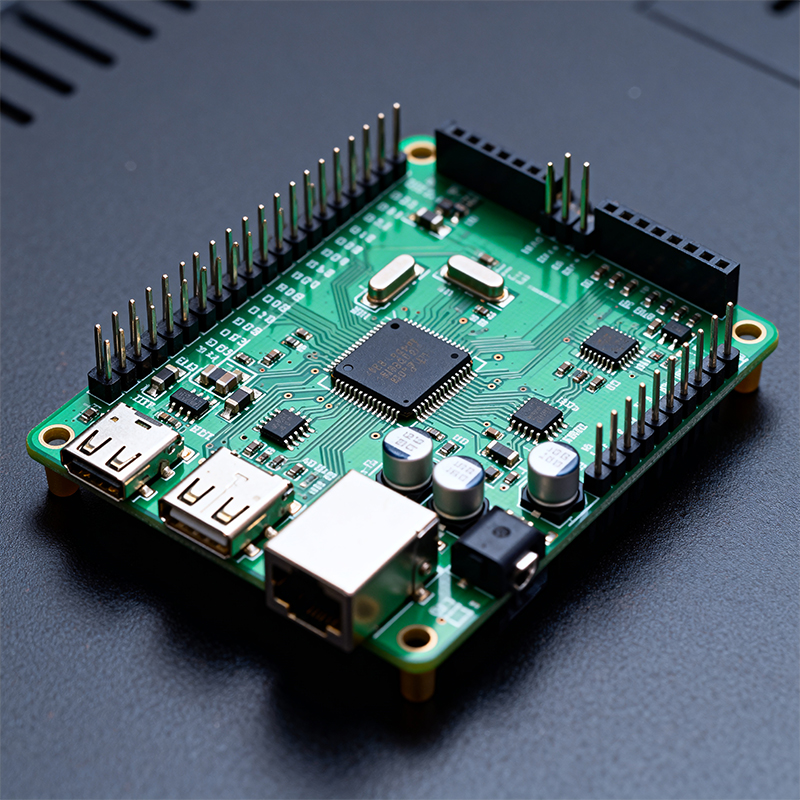

Purpose: Accelerated prototyping for specific technologies (e.g., Arduino, Raspberry Pi, ESP32)

Structure: Integrated systems with pre-mounted processors, memory, and I/O interfaces

Advantages: Dramatically reduces development time; extensive community support

Application: Perfect for firmware development and proof-of-concept demonstrations

Low Complexity: Breadboards or perfboards suffice for simple circuits with under 20 components

Medium Complexity: Stripboards or small custom PCBs for analog/digital hybrid circuits

High Complexity: Custom prototype PCBs essential for BGA components, RF circuits, or impedance-controlled designs

Functional Testing: Basic prototypes that verify circuit operation

Performance Testing: Prototypes that must match final product specifications (speed, noise, power)

Environmental Testing: Prototypes subjected to thermal, vibration, or humidity conditions

Regulatory Testing: Prototypes used for EMC/EMI, safety, or compliance pre-certification

Rapid Iteration: Solderless boards allow immediate changes but lack production realism

Balanced Approach: Quick-turn PCBs offer reasonable speed with better fidelity

Cost Management: Budget allocation across multiple prototype revisions

Design for Manufacturability (DFM): How well the prototype informs production decisions

Component Sourcing: Whether prototype components match production availability

Scalability: Ease of transitioning from prototype to mass production

Tools: EDA software (Altium, KiCad, Eagle)

Output: Validated circuit schematic

Purpose: Theoretical verification before physical implementation

Decision Factors: Circuit complexity, testing needs, budget, timeline

Output: Selected prototyping methodology

Manual Assembly: Hand-soldering components for early prototypes

Machine Assembly: Automated pick-and-place for custom prototype PCBs

Output: Functional physical prototype

Electrical Testing: Voltage, current, signal integrity measurements

Functional Testing: Verifying all intended operations

Debugging: Identifying and resolving design flaws

Output: Refined, validated design

Iteration: Incorporating test findings into improved designs

Documentation: Recording all changes and test results

Output: Production-ready design files

Problem: Noise, crosstalk, or reflections in high-speed circuits

Solution: Use custom prototype PCBs with proper grounding and impedance control

Problem: Overheating components not apparent in simulation

Solution: Incorporate thermal testing early; use prototype PCBs with production-like thermal characteristics

Problem: Designs that work in prototype but can't be efficiently manufactured

Solution: Involve manufacturing expertise during prototyping phase

Problem: Prototype components differ from production versions

Solution: Source components through channels that reflect production supply chains

Problem: Multiple expensive prototype iterations

Solution: Strategic prototype planning; simulate thoroughly before building

Effective prototyping bridges innovative design with reliable manufacturing—a transition where many projects encounter difficulties. At Kaboer, we understand that a prototyping board is more than just a test platform; it's the critical link between concept and market-ready product.

Based in Shenzhen, China—the global epicenter of electronics manufacturing—Kaboer offers a seamless pathway from prototype to production:

Rapid Prototype PCB Fabrication

Quick-turn manufacturing (24-72 hours) for custom prototype PCBs

Support for complex requirements: impedance control, blind/buried vias, HDI designs

Material selection guidance for optimal performance and cost

Professional Prototype Assembly

Small-batch SMT assembly with the same precision as production runs

Comprehensive component sourcing, including hard-to-find parts

Mixed-technology assembly (SMT, through-hole, press-fit)

Design for Manufacturability (DFM) Analysis

Early identification of production challenges while still in prototyping

Practical recommendations to improve yield, reliability, and cost-effectiveness

Smooth transition from prototype to mass production

Testing and Validation Support

In-circuit testing (ICT) and flying probe testing for prototype verification

Functional testing to ensure performance matches specifications

Environmental stress screening when required

Seamless Scaling to Production

Identical manufacturing processes from prototype through mass production

Consistent quality control across all volumes

Supply chain management that ensures component continuity

Whether you need a single prototyping board for concept validation or a batch of functional prototypes for field testing, Kaboer provides the manufacturing expertise to ensure your designs are not only functional but production-ready. Our integrated approach eliminates the gap between prototyping and manufacturing, giving you confidence that what works in prototype will work in volume production.

A prototyping board represents far more than a temporary test platform—it's an essential investment in product success. By selecting the appropriate prototyping strategy and partnering with a manufacturer that understands the complete development cycle, electronics companies can:

Reduce time-to-market through faster, more effective iterations

Minimize costly redesigns by identifying issues early

Ensure smoother transitions to mass production

Develop higher quality, more reliable products

In today's competitive electronics landscape, strategic prototyping isn't just an engineering phase—it's a business imperative that separates market leaders from the rest.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..