Date: 2026-01-07

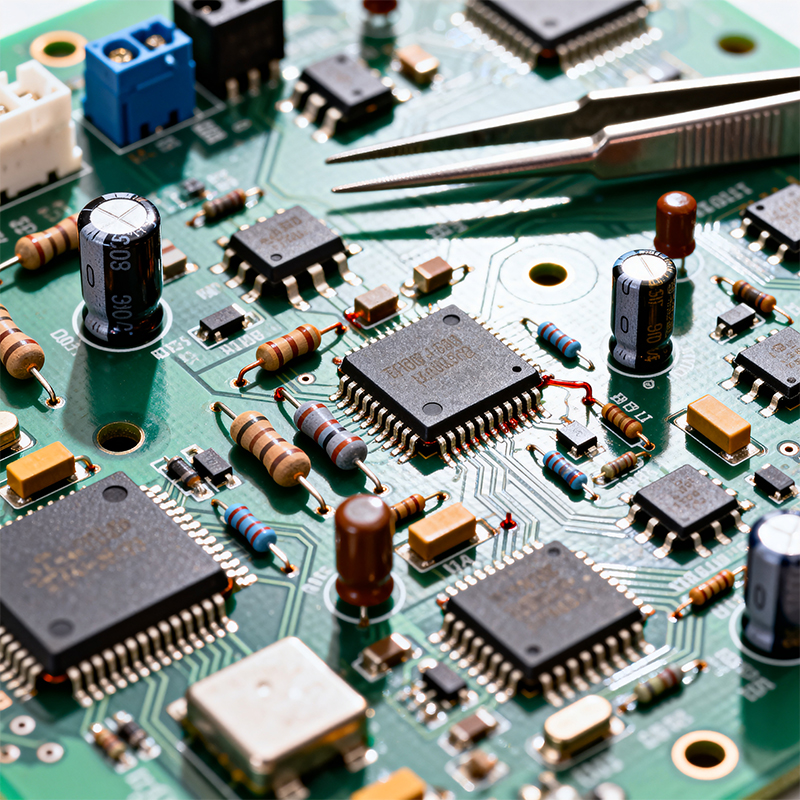

The design is ready, and the components are at hand. The next step is bringing them together into a reliably functioning whole. At this stage, many hardware teams face a similar fork in the road: complete the assembly on their own workbench, or entrust it to a professional production line.

Assembly at the workbench has its own merits. Engineers gain an intimate, hands-on understanding of every design detail through soldering and debugging. A few prototypes or a few dozen samples can often be efficiently verified with skilled hands and basic tools. It's flexible and direct, an indispensable phase in early product development.

However, when quantities move from "dozens" to "hundreds" or more, the scene shifts from the workbench to the production line. Here, the focus changes from "how to make one" to "how to make hundreds or thousands, all identically." Consistency, efficiency, and traceability become the new keywords.

At Kaboer's factory in Shenzhen, we navigate this transition from "project" to "product" daily. We see how, when assembly moves from occasional manual work to a systematic production process, previously hidden issues—like the soldering yield of a specific component under a precise temperature profile, or minor variations between material batches—come to light and are addressed methodically.

The choice often depends on specific circumstances:

Volume and Rhythm: If the need is for a small number of rapidly iterated validation units, manual assembly might be more agile. But if the goal is the stable delivery of hundreds or thousands, the scale and discipline of a production line become irreplaceable.

Design Complexity: The assembly requirements for a simple board with a few discrete components are worlds apart from those of a multi-layer motherboard integrating hundreds of miniature parts. The latter typically demands precise automation and controlled environments.

The Definition of "Reliability": If the product will be used in demanding conditions, or if expectations for long-term stable operation are high, then a production process incorporating Automated Optical Inspection (AOI), X-ray checks, and systematic functional testing is often a necessary foundation to meet that standard.

Allocation of Team Energy: When calculating input, beyond visible parts and processing costs, it's also worth considering the "time cost" of your core team. Should valuable R&D effort focus on design optimization and problem-solving, or be continually invested in repetitive assembly and basic inspection?

Working with a professional assembly partner typically starts with handing over design files and a Bill of Materials (BOM), but it goes much further. A thorough collaboration often includes:

Design for Manufacturability (DFM) Review: An experienced engineering team examines the design from a production standpoint, suggesting adjustments for details that could affect yield, efficiency, or reliability. This can prevent many late-stage design changes.

Material Kitting and Verification: A professional factory manages component sourcing, inspection, and preparation, ensuring the correct, qualified parts are used on the line.

A Transparent Process and Delivery: You get clear visibility into the production status, key test results, and ultimately receive fully validated finished goods ready for integration or use.

At Kaboer, we see ourselves as an extension of our clients' manufacturing capability. Our owned factory in Shenzhen is not just a collection of equipment, but a carrier of processes, experience, and quality control systems. We understand that maintaining the same high standard from the first sample to the last unit is the foundation of trust.

Whether you choose to complete crucial initial verification on your own workbench or to engage professional manufacturing capability at the right time, the core goal remains the same: to move your product more robustly from concept to reality. Understanding the characteristics of each path may help you navigate this common crossroads with greater clarity.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..