Date: 2026-01-07

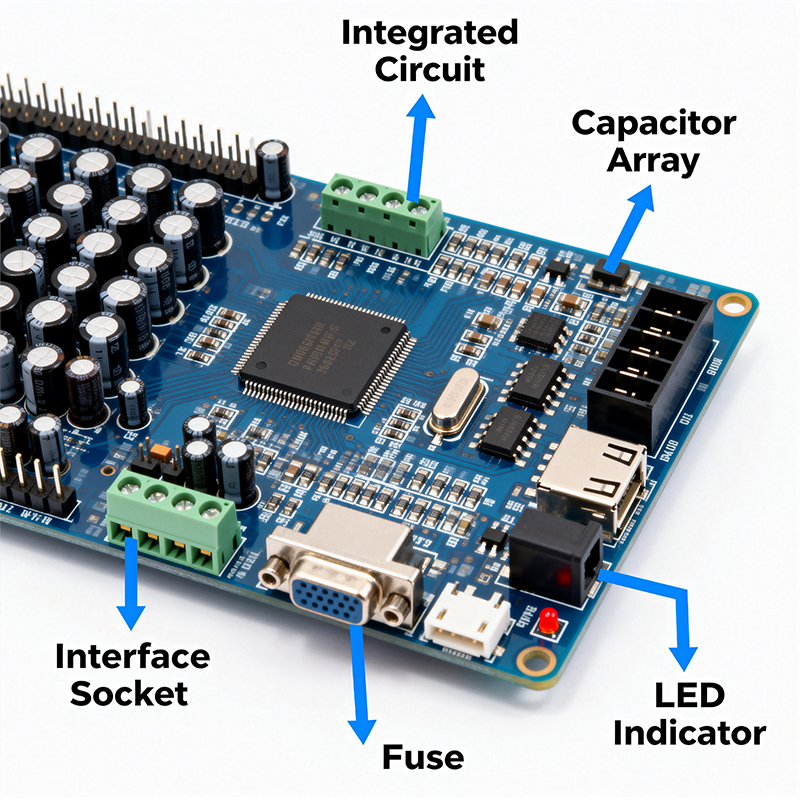

You’re holding a populated circuit board, looking at a sea of components of all sizes—especially those little black squares with a few lines of code that look like ciphers. You need to know their exact part number, or your production line has received a batch of poorly labeled materials. At times like these, identifying PCB components becomes the critical first step.

Identifying components on a PCB isn't about guessing; there's a method to it. Based on our experience with various boards in Shenzhen, here’s a typical approach:

Step 1: Start with Clues on the Board Itself

Most well-designed PCBs have silkscreen markings—those white characters. “R” usually indicates a resistor, “C” a capacitor, “U” or “IC” an integrated circuit, “L” an inductor, “D” a diode. Find the marking next to the component (like “U5”), and you can locate it in the schematic or Bill of Materials (BOM).

Step 2: Decode the “Cipher” on the Component Body

The markings on the component itself are key. For chips (ICs), the code usually has two parts:

One line: Typically the main part number. E.g., “STM32F407VGT6”.

Another line: Usually a lot/date code or origin info. Useful for traceability, but not the part number.

Search Tip: Type the clearest, longest line of code from the component directly into a search engine; it often works. If the code is too vague, combine it with physical traits like size (e.g., 3mm x 3mm), pin count, and package shape (e.g., SOT-23, QFN) in your search.

Step 3: Leverage Free Tools & Communities

Chip Lookup Websites: Some sites specialize in cataloging chip codes.

Mobile Apps: Certain apps can help identify common components via photo.

Electronics Forums: Post clear photos on relevant forums; the community can be incredibly helpful.

Step 4: Professional Instrument Testing

For components like transistors or diodes, a multimeter’s diode test function can provide basic clues. In more advanced scenarios, even X-ray might be used to examine internal structures for identification.

Real life can be more challenging:

Scratched-off Codes: Sometimes done for confidentiality or on refurbished parts. You may need to deduce the part from circuit function, surrounding components, and pinout.

Fully Custom Parts: These might only have a supplier's internal number. You’ll need to contact the original designer or potential supplier directly.

For teams regularly handling different boards, building a system can greatly improve efficiency:

Build an Internal Component Database

Document verified components—their codes, photos, sources—in an internal database. The next time you see the same code, you’ll have the answer instantly.

Improve File Management

Ensure every design version has a complete, accurate BOM (Bill of Materials) and assembly drawing on file. This is the most authoritative reference.

Collaborate Closely with Your Manufacturer

An experienced PCBA manufacturer (like Kaboer in Shenzhen) can be a huge asset. We see a vast array of components daily and become familiar with common codes. More importantly, we can implement standardized processes—from strict labeling during material intake and machine setup verification to scan checks on the line—to eliminate the question of “what is this component?” at the source.

At Kaboer, we understand that accurate component identification is the starting point for reliable production. Our process begins with rigorous BOM verification and component qualification. For components with unclear or special codes, our engineering team leverages experience and resources to confirm identities, ensuring every part placed on the line is correct.

Core Advice: If component identification is a recurring bottleneck in your projects, it might be time to review your entire workflow from design to material management. Maintaining clear “identity” for every component, from design files to physical boards, is fundamental to ensuring product quality and production efficiency.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..