In the fast-paced world of automotive manufacturing, where new EV models and ADAS upgrades hit the market every quarter, flexibility isn’t just an advantage—it’s a survival skill. nowhere is this truer than in the production of automotive flexible printed circuits (FPCs), the intricate "nervous systems" that power everything from battery management to radar sensors. Traditional FPC production lines, bogged down by manual adjustments and paper-based processes, struggle to keep up with the demand for frequent changeovers. But digitalization is changing the game. Here’s how smart factories are using data, AI, and connected systems to slash changeover times and stay ahead in the race.

The High Stakes of FPC Changeovers

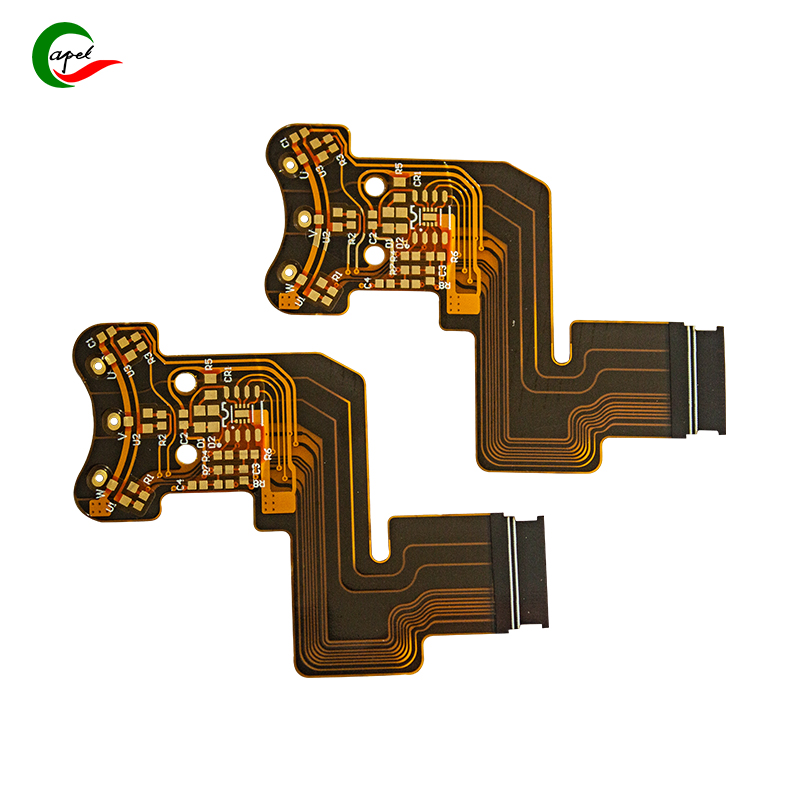

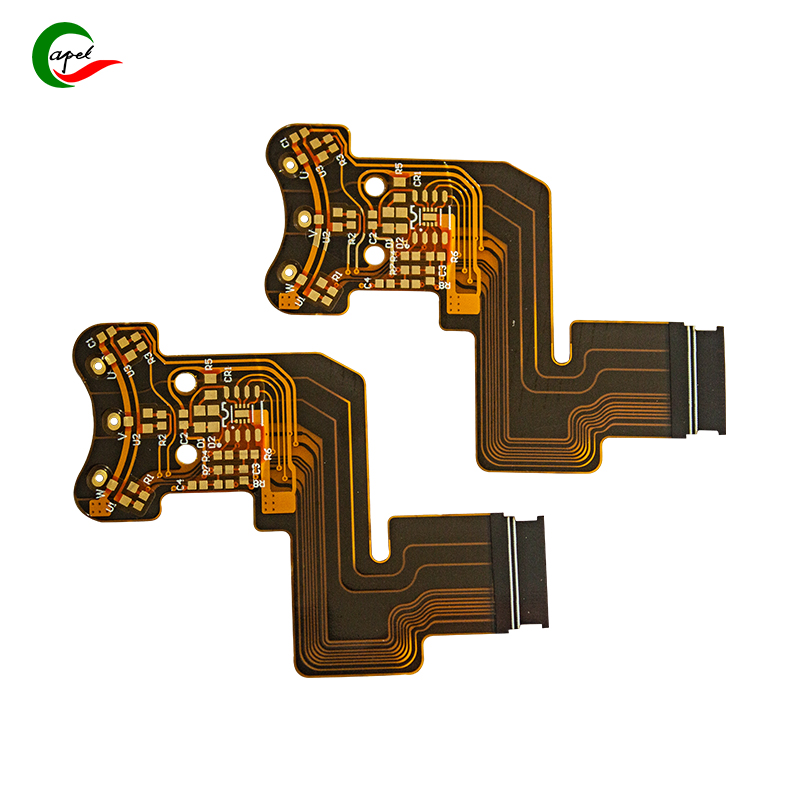

Automotive FPCs aren’t one-size-fits-all. A single car model might require dozens of unique FPC designs—from 0.1mm-thin battery sensors to rugged motor-control circuits. When a factory switches from producing one FPC variant to another, every step of the process must reset: laser etching patterns, lamination parameters, inspection criteria, and even material handling.

In traditional setups, this can take 8–12 hours per changeover. For high-volume plants churning out 10,000+ FPCs daily, those hours translate to lost capacity, missed deadlines, and inflated costs. Worse, manual adjustments (like recalibrating a laser for a new circuit pattern) introduce human error, increasing defect rates—a disaster in automotive manufacturing, where a single faulty FPC can trigger recalls.

Digitalization: The Three Pillars of Rapid Changeover

Forward-thinking FPC factories are leveraging digital tools to collapse changeover times to under 2 hours—and in some cases, under 30 minutes. The transformation rests on three interconnected pillars:

1. Digital Twins: Virtual Testing Cuts Physical Trial-and-Error

At the heart of rapid changeover is the digital twin—a 3D virtual replica of the FPC, production line, and even the end-use environment (like a car’s battery pack). Here’s how it works:

- Design-to-production sync: When an engineer finalizes a new FPC design (say, for a next-gen ADAS radar), the digital twin automatically generates production parameters—laser power settings, etchant concentrations, and lamination pressure—based on historical data from similar designs. No more manual recipe writing.

- Virtual commissioning: Before the first physical FPC is made, the digital twin simulates the entire production run. It flags potential issues: Will the new coverlay material cause lamination bubbles at 180°C? Does the 50μm line width require a finer laser focus? Fixes happen in the virtual world, slashing physical trial runs from days to hours.

- Real-time adaptation: Sensors on the production line feed data back to the digital twin (e.g., "etchant temperature spiked by 2°C"). The twin adjusts parameters on the fly, ensuring consistency even as conditions change—critical for maintaining quality during changeovers.

2. AI-Driven Process Automation: From Buttons to Brainpower

Gone are the days of technicians manually swapping out stencils or reconfiguring inspection cameras. AI-powered automation is taking over:

- Smart equipment calibration: Laser etchers and pick-and-place machines now use computer vision and machine learning to recognize new FPC designs. A camera scans the first panel of a new batch, compares it to the digital blueprint, and auto-adjusts alignment (to within ±1μm) in seconds—no human input needed.

- Predictive tooling changes: AI algorithms analyze wear patterns on drill bits and laser heads. When a tool nears the end of its useful life (based on 10,000+ previous cycles), the system alerts operators to replace it during a changeover, avoiding unplanned downtime later.

- Adaptive quality checks: Machine learning models trained on 100,000+ FPC images can instantly switch between inspection criteria. A battery FPC’s thermal sensor pads require stricter dimensional checks than an infotainment circuit’s traces—the AI knows the difference and adjusts its checks accordingly.

3. Connected Supply Chains: Materials Ready When You Are

Even the fastest production line grinds to a halt if materials (e.g., a specific PI substrate or 35μm rolled copper) aren’t ready. Digital supply chains solve this with:

- Demand-sensing algorithms: When a carmaker orders 5,000 units of a new battery FPC, the FPC factory’s ERP system automatically signals suppliers to deliver exact quantities of materials—timed to arrive 2 hours before the changeover starts. No overstock, no delays.

- Traceability twins: Every material batch (from copper foil to adhesives) has a digital ID linked to its specs (e.g., "PI film, 0.05mm thickness, lot #782"). During changeover, the production system scans these IDs to confirm they match the new FPC’s requirements—preventing costly mix-ups.

- Just-in-time (JIT) material staging: Autonomous guided vehicles (AGVs) in the factory, coordinated by IoT sensors, deliver reels of copper or coverlay to the exact machine at the exact moment of changeover. No more technicians hunting for materials across the plant.

The Results: Speed, Quality, and Scalability

Factories embracing this digital approach report transformative results:

- Changeover times reduced by 70–80%: A leading Tier 1 supplier cut switchover from 10 hours to 90 minutes, increasing annual capacity by 15%.

- Defect rates dropped by 50%: AI inspections and digital twin simulations caught issues early, slashing rework costs.

- Scalability for 100+ variants: A European FPC maker now produces 120 unique automotive FPC designs monthly—up from 30—without adding shifts.

The Road Ahead: Digitalization as a Competitive Edge

As automotive FPCs grow more complex (think 5G-enabled V2X circuits or self-healing battery sensors), changeovers will only get trickier. Factories stuck in manual processes will fall further behind. Those investing in digital twins, AI automation, and connected supply chains won’t just keep up—they’ll set the pace.

For automotive manufacturers, the message is clear: To win in tomorrow’s market, your FPC production must be as smart, flexible, and fast as the cars they power. Digitalization isn’t just a tool—it’s the fuel for the next industrial revolution in FPC manufacturing.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.