Last year, my team was tasked with designing a luxury car’s dashboard featuring three screens: a 12-inch main infotainment display, a 7-inch driver’s instrument cluster, and a 5-inch passenger media touchscreen. By week four, our prototype looked like a scene from a robotics movie: dozens of wires snaked between the screens, connecting to a central rigid PCB. “We can’t fit this behind the dashboard,” our mechanical engineer, Carlos, said, holding up a tangled bundle. “The wires block the air vents, and if one comes loose, the whole system crashes.”

During a late-night brainstorm, our electrical lead, Priya, pulled out a sample FPC (Flexible Printed Circuit). “What if we replace all these wires with one flexible board?” she said. We were skeptical—could a single film replace 20+ wires? But within two weeks, we had a redesign: a single FPC routed behind the dashboard, linking all three screens to the car’s main computer. No tangles, no blocked vents, no loose connections. “It’s like the dashboard finally ‘breathes,’” Carlos said.

That experience taught us why FPCs are revolutionizing car dashboards: multi-screen setups demand wiring that’s flexible, compact, and reliable. Traditional wires and rigid PCBs turn dashboards into chaotic mazes—but FPCs turn chaos into order.

Modern cars aren’t just adding screens—they’re adding connected screens (e.g., the infotainment system sharing data with the instrument cluster). Traditional wiring (loose wires + rigid PCBs) can’t keep up, and here’s why:

Each screen needs 4–6 wires (power, data, ground, touch control). For three screens, that’s 12–18 wires—plus extra wires for sensors (like a cabin temperature sensor linked to the infotainment system). These wires twist together behind the dashboard, blocking airflow (causing overheating) and breaking when the dashboard vibrates.

“We tested the wire-based prototype on a vibration rig (simulating driving on a bumpy road),” Carlos said. “After 8 hours, two wires came loose— the instrument cluster went dark, and the infotainment system froze. A driver would panic if that happened on the highway.”

A central rigid PCB needs to be large enough to connect all screens—often 15cm × 10cm. This forces the dashboard to be thicker (to fit the PCB) and limits where screens can be placed (they have to be within wire length of the PCB).

Our first rigid PCB design made the dashboard 3cm thicker than the carmaker’s target. “We had to move the passenger screen 5cm closer to the center, which ruined the dashboard’s symmetry,” Priya said. “The carmaker hated it—they wanted the screens to be spread out for a luxury look.”

Traditional setups use connectors to link wires to screens and the PCB. Every time the car vibrates, these connectors wiggle loose. Fixing them means disassembling half the dashboard—a 2-hour job for a mechanic.

“We had a test where we had to remove the dashboard to reattach a loose connector,” Carlos said. “It took 1.5 hours, and we accidentally broke a plastic clip. For a production car, that’s a nightmare—dealers would hate servicing it.”

FPCs solve the three biggest problems with traditional wiring by being flexible, compact, and integrated. Here’s how they transformed our dashboard design:

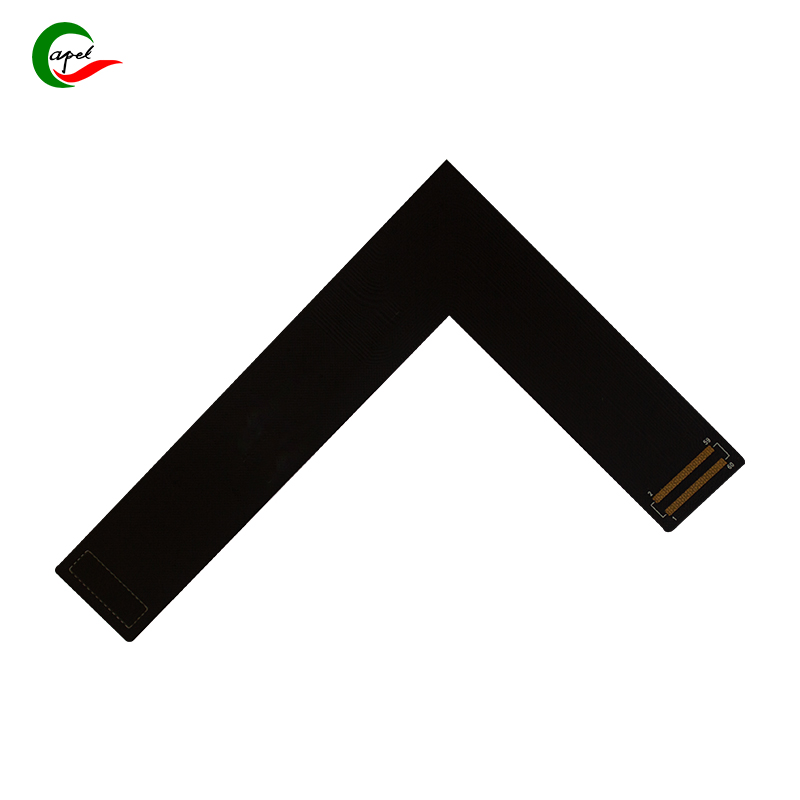

An FPC is a single thin film (0.1mm thick) with multiple copper traces printed on it. For our three-screen dashboard, we designed an FPC with 12 traces: 4 for each screen (power, data, ground, touch). This replaced 12 separate wires—no tangles, no blocked vents.

We routed the FPC along the dashboard’s inner edge, behind the air vents (not through them). It fit in a 2mm gap between the dashboard frame and the plastic cover—space that wires would never fit in. “We could even bend it around the steering column without squeezing it,” Carlos said. “Wires would have gotten crushed there.”

Map the dashboard’s “empty spaces” (like gaps between vents or behind trim) first, then design the FPC to follow those paths. This keeps the FPC out of the way of moving parts (like the steering column).

FPCs bend and curve, so screens don’t have to be near a central PCB. We placed the driver’s cluster behind the steering wheel, the main screen in the center, and the passenger screen on the far right—all connected by a single FPC that snaked between them.

The carmaker wanted the dashboard to be 2.5cm thick—thinner than our original rigid PCB design. The FPC’s thinness let us meet that target: “We didn’t have to move any screens to fit wiring,” Priya said. “The dashboard kept its luxury symmetry, and the carmaker loved it.”

Use “branches” on the FPC to connect to each screen. Our FPC had two small branches (5cm long) for the driver and passenger screens—like a tree trunk with two small limbs. This avoids having to run separate wires to each screen.

An FPC is a single continuous board—no connectors between the main FPC and the screens. We soldered the FPC directly to each screen’s connector, eliminating loose connections. If a screen fails, you just disconnect the FPC’s small connector (hidden behind a trim piece) instead of disassembling the whole dashboard.

We tested the FPC-based dashboard on the vibration rig for 24 hours—no loose connections, no screen failures. “Even when we hit the dashboard with a rubber mallet (simulating a pothole), the screens stayed on,” Carlos said. “With wires, they would have cut out.”

Add small “strain relief” loops to the FPC near each screen. These loops absorb vibration so the soldered connections don’t break. Our loops were 1cm long—enough to handle the car’s vibration without adding bulk.

Not all FPCs work for car dashboards—you need to design for temperature, vibration, and durability. Here are the tips that made our design successful:

Car dashboards get hot—up to 60°C in direct sunlight. Use PI film rated for 150°C (like DuPont Kapton) instead of standard PI film (rated for 100°C). This prevents the FPC from melting or warping.

We used 0.125mm-thick Kapton PI film. We tested it in an oven at 70°C for 48 hours—no warping, no trace damage. “Standard PI film would have started to curl at 60°C,” Priya said. “That would have broken the connections to the screens.”

The FPC bends most near the screens and the steering column—these are “stress points” where the film can tear. Add small FR4 stiffeners (0.2mm thick) to these areas to strengthen them.

We glued 3mm × 5mm FR4 stiffeners to the FPC where it connected to each screen and where it bent around the steering column. “We tested the FPC by bending those points 1,000 times,” Carlos said. “No tearing— the stiffeners worked perfectly.”

Cars have electromagnetic interference (EMI) from the engine, radio, and GPS. Add a thin copper shield layer to the FPC to block EMI—this prevents screen glitches (like the infotainment system freezing).

We printed a 0.01mm-thick copper shield on the back of the FPC. We tested it next to the car’s engine—no screen glitches, no data loss. “Without shielding, the main screen would have flickered every time the engine revved,” Priya said.

After applying these tips, the carmaker approved our design for production. Here’s how it performed in final tests:

A dealer technician who tested the dashboard said: “This is the easiest multi-screen dashboard I’ve ever serviced. If a screen fails, I just pop off the trim, disconnect the FPC, and swap the screen. No more tangled wires, no more broken clips.”

Our “wire maze” dashboard taught us that multi-screen car interiors need wiring that’s as flexible and smart as the screens themselves. Traditional wires and rigid PCBs are relics of single-screen dashboards—FPCs are built for the future.

As cars add more screens (think rear-seat entertainment or smart mirrors), FPCs will become even more essential. They let designers create sleeker, more luxurious dashboards that are reliable for drivers and easy to service for mechanics.

Next time you sit in a car with multiple screens, take a second to wonder: is there an FPC behind that dashboard? If the screens are spread out, the dashboard is thin, and everything works smoothly, chances are the answer is yes. And that’s the power of FPCs in car dashboards.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.