Last quarter, my team was designing a control module for a heavy-duty construction crane. We needed a flexible board to connect the module’s sensors to the main computer—something that could handle vibration, dust, and occasional impacts. We went with a standard FPC (Flexible Printed Circuit) because it was cheaper and easier to source.

Six weeks later, the client called in a panic: three cranes had shut down because the FPCs had torn near the sensor connectors. “The constant vibration from the crane’s engine pulled the FPC apart,” our field engineer, Mark, said after inspecting the failed boards. We had to rush to replace all 50 FPCs with rigid-flex PCBs—and the client billed us for $10,000 in downtime.

That mistake taught us a critical lesson: in industrial applications, choosing between rigid-flex PCBs and FPCs isn’t about “which is better”—it’s about “which fits the job.” FPCs work for simple, low-stress tasks, but rigid-flex PCBs handle the heavy-duty, high-stress environments that industrial gear lives in.

First, let’s clarify the basics—because in industrial settings, small differences matter:

-

FPC (Flexible Printed Circuit): A single thin layer of PI film with copper traces. It’s lightweight, super flexible, and great for simple connections (e.g., linking a sensor to a board). But it has no rigid sections—so heavy components (like connectors or microchips) have to be mounted elsewhere, and it’s weak against repeated stress.

-

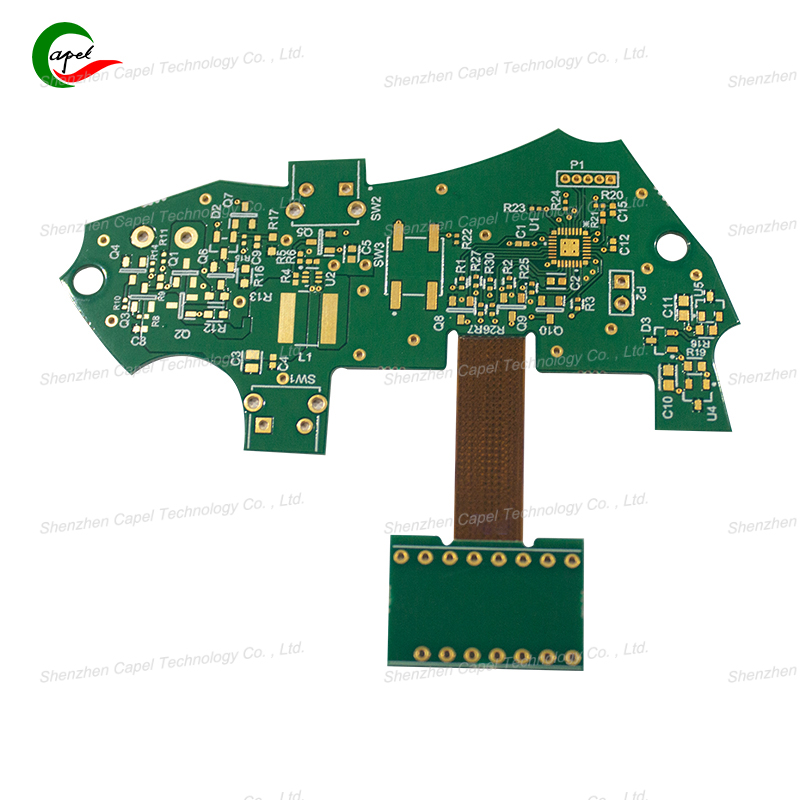

Rigid-Flex PCB: Combines flexible PI sections (for bending) with rigid FR4 sections (for mounting components). It’s more durable than FPCs, can hold heavy parts directly, and handles vibration/impacts better. But it’s more expensive and takes longer to manufacture.

“In consumer devices (like smartwatches), FPCs are fine—they’re not exposed to constant vibration or heavy impacts,” Mark said. “But in industrial gear (cranes, factories, mining equipment), FPCs break too easily. Rigid-flex is built for that abuse.”

The right choice depends on three things: the environment (vibration, moisture, temperature), the need for component mounting, and the budget. Below are the most common industrial scenarios, and which board works best:

Industrial equipment like cranes or assembly-line robots vibrate constantly and often take small impacts (e.g., a tool bumping the control module). FPCs fail here because their thin PI film tears under repeated stress, and their loose connections wiggle free.

-

Rigid sections hold components securely: Heavy connectors or microchips mount directly on the FR4 sections—no loose wires to shake free.

-

Reinforced transition zones: The area where flexible PI meets rigid FR4 is reinforced with adhesives or stiffeners, so it doesn’t tear under vibration.

After replacing FPCs with rigid-flex PCBs, the crane modules ran for 6 months without a single failure. “The rigid sections kept the connectors tight, and the flexible sections bent with the crane’s movement without tearing,” Mark said. “We haven’t had a call from the client since.”

If the equipment vibrates more than 50Hz (common in factory machines) or could be hit by tools/parts, FPCs will fail within months.

Not all industrial gear is high-stress. For simple tasks—like connecting a row of temperature sensors to a main board, or linking a lightweight handheld tool’s display to its battery—FPCs work perfectly.

-

Cheaper and faster to make: FPCs cost 30–50% less than rigid-flex PCBs for simple designs. Our team used FPCs for a sensor array in a food factory—we saved $2 per unit, which added up to $1,000 for 500 sensors.

-

Thinner and lighter: FPCs are 0.1mm thick (vs. 1–2mm for rigid-flex), so they fit in tight spaces (like between food processing belts) where rigid-flex can’t.

A food factory needed 500 temperature sensors along a conveyor belt. We used FPCs to link each sensor to a central board—they fit in the 2mm gap between the belt and the frame, and they’ve run for a year without issues. “The sensors don’t vibrate much, and there’s no risk of impact,” said the factory’s maintenance manager. “FPCs were the right call.”

If the design is simple (no heavy components, low vibration) and budget is tight, rigid-flex is overkill—you’ll pay extra for durability you don’t need.

Some industrial gear (like medical imaging machines or precision measuring tools) needs both flexibility and durability: they need to bend around moving parts (like a machine’s arm) but also hold sensitive components (like a laser sensor) securely.

-

Balances flexibility and stability: The flexible sections bend around moving parts, while the rigid sections hold sensitive components steady—critical for precision.

-

Reduces wire count: Rigid-flex combines multiple connections into one board, so there are fewer wires to interfere with sensitive instruments (like medical scanners).

We designed a rigid-flex PCB for a portable ultrasound machine. The flexible section bent around the machine’s handle, and the rigid section held the ultrasound sensor and battery. “FPCs would have needed extra wires to connect the sensor, which could interfere with the ultrasound signal,” Mark said. “Rigid-flex kept everything integrated and stable.”

If the device is super lightweight (under 500g) and the components are tiny (like 0201 capacitors), FPCs could work—but only if there’s no risk of vibration or impact.

To avoid picking the wrong board, use this checklist before deciding:

Our crane mistake happened because we skipped the first question—we didn’t consider the crane’s vibration. “If we’d used this checklist, we would have picked rigid-flex from the start,” Mark said. “We wouldn’t have cost the client $10,000.”

Let’s break down the costs of our crane project before and after switching to rigid-flex—so you can see how the “cheaper” option can cost more in the long run:

The FPCs were cheaper upfront, but the downtime and replacements made them 6x more expensive. “Industrial projects aren’t about the initial cost—they’re about total cost of ownership,” Mark said. “Rigid-flex costs more at first, but it saves money later.”

Our crane disaster taught us that in industrial settings, there’s no “one-size-fits-all” flexible board. FPCs are great for simple, low-stress tasks where budget matters. Rigid-flex PCBs are for high-stress, heavy-duty jobs where durability and stability are non-negotiable.

The next time you’re choosing between them, ask: What will this board go through every day? If it’s vibration, impacts, or heavy components—go with rigid-flex. If it’s simple connections and low stress—FPCs are fine.

Don’t make our mistake: picking the cheaper option without thinking about the industrial environment will cost you more in downtime, replacements, and client trust. Choose wisely—and your project will run smoothly for years.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.