Choosing an FPC Manufacturer: Key Considerations

Date: 2025-08-12

Selecting the right Flexible Printed Circuit (FPC) manufacturer is a critical decision that directly impacts the success of your electronic projects. FPCs are integral to devices ranging from consumer electronics to industrial equipment, making their quality and reliability paramount. Below is a structured breakdown of the essential factors to evaluate when making your choice.Quality is non-negotiable in FPC production, and certifications serve as tangible proof of a manufacturer’s commitment to standards.

- Global Certifications: Prioritize manufacturers with ISO 9001 (quality management) and ISO 14001 (environmental management) certifications. For medical or automotive applications, look for ISO 13485 or IATF 16949, respectively.

- Industry Standards: Ensure compliance with IPC standards (e.g., IPC-A-600 for printed circuits) and RoHS/REACH for environmental safety. These standards guarantee consistency in material quality and production processes.

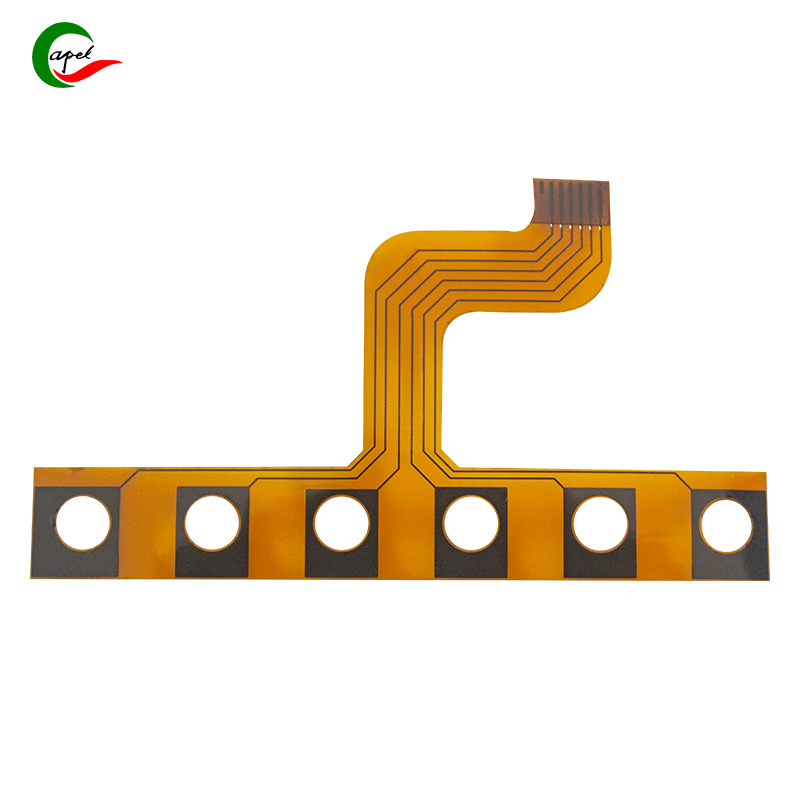

FPCs vary widely in complexity—from simple single-layer designs to multi-layer, high-density interconnect (HDI) boards. A reliable manufacturer should demonstrate:

- Advanced Equipment: Access to automated optical inspection (AOI), laser drilling, and precision etching machines ensures accuracy for tight tolerances (e.g., 0.1mm line/space).

- Flexibility in Scale: Ability to handle both prototyping (small batches, 1–100 units) and mass production (10,000+ units) to adapt to your project’s lifecycle.

- Material Expertise: Proficiency with diverse substrates (e.g., PI, PET) and finishes (e.g., gold plating) to match your application’s needs (e.g., high-temperature resistance for automotive use).

The quality of FPCs hinges on the materials used, making supply chain stability critical.

- High-Quality Materials: Reputable manufacturers source substrates, adhesives, and conductive foils from trusted suppliers (e.g., Dupont, Toray) and provide material traceability reports.

- Risk Mitigation: Inquire about strategies for avoiding delays, such as maintaining safety stocks of key materials or partnering with backup suppliers to handle shortages.

Beyond production, a manufacturer’s ability to collaborate on design can streamline your project.

- DFM Services: Design for Manufacturability (DFM) support helps optimize your FPC layout for cost-efficiency and yield, reducing errors during production.

- Technical Responsiveness: Look for teams that offer quick feedback on design feasibility, troubleshooting, and customization (e.g., flexible bending radius for wearable devices).

Balancing cost and quality is key, but avoid compromising on reliability for lower prices.

- Transparent Pricing: Ensure quotes include details on materials, testing, and shipping to avoid hidden costs.

- Consistent Lead Times: Verify the manufacturer’s track record for meeting deadlines, especially for time-sensitive projects.

- Customer Feedback: Check reviews or request references to gauge past performance—prompt communication and post-sales support are indicators of a trustworthy partner.

By evaluating a manufacturer’s certifications, technical capabilities, supply chain stability, collaborative support, and reliability, you can select a partner that aligns with your project’s needs. The right FPC manufacturer will not only deliver high-quality products but also contribute to the efficiency and success of your entire production process.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.