In the rapidly evolving electronics industry, the quality of Flexible Printed Circuits (FPCs) and multilayer PCBs directly determines the performance and durability of end - use products. Whether you are engaged in the production of consumer electronics, medical devices, or automotive electronics, selecting a reliable manufacturer is crucial. This article will detail the key factors for choosing an FPC manufacturer and the evaluation criteria for multilayer PCB and flexible circuit board production capabilities.A reliable FPC manufacturer must hold internationally recognized certifications. ISO 9001 certification ensures that it has a sound quality management system. For manufacturers involved in the medical field, ISO 13485 certification is indispensable. In the automotive electronics sector, IATF 16949 certification is a must - have. These certifications are not just pieces of paper; they reflect the manufacturer's strict adherence to industry standards in production processes, quality control, and product testing.

The technical team is the core of a manufacturer. Excellent engineers should have rich experience in FPC design and production, being able to provide professional solutions for complex product requirements. At the same time, strong R & D capabilities mean that the manufacturer can keep up with the latest technological trends, such as the development and application of high - density flexible circuits, to meet the ever - changing market demands.

Advanced production equipment is the guarantee of product quality. High - precision laser cutting machines, automated optical inspection (AOI) systems, and reliable lamination equipment can ensure the accuracy and consistency of FPCs. In terms of quality control, strict incoming material inspection, in - process inspection, and final inspection procedures must be in place to minimize the rate of defective products.

On - time delivery is crucial for the smooth progress of the entire project. A reliable manufacturer will have a reasonable production plan and supply chain management to ensure that products are delivered on time. In addition, perfect after - sales service is also essential. If there are any problems with the products, the manufacturer should respond promptly and provide effective solutions.

The ability to produce multilayer PCBs with a higher layer count (such as 20 layers or more) reflects the manufacturer's technical strength. At the same time, a reasonable stack - up design can reduce signal interference and improve the performance of the circuit board. Manufacturers should be able to design appropriate stack - ups according to the product's functional requirements.

Fine line width and line spacing are important indicators of the manufacturing level of multilayer PCBs. The smaller the line width and line spacing (for example, 3mil/3mil or even smaller), the higher the requirements for the manufacturer's process technology, which can accommodate more components and improve the integration of the circuit board.

High - quality hole making is critical for multilayer PCBs. The accuracy of through - holes, blind holes, and buried holes directly affects the electrical conductivity and reliability of the circuit board. Manufacturers should master advanced hole making technologies such as laser drilling to ensure the quality and precision of the holes.

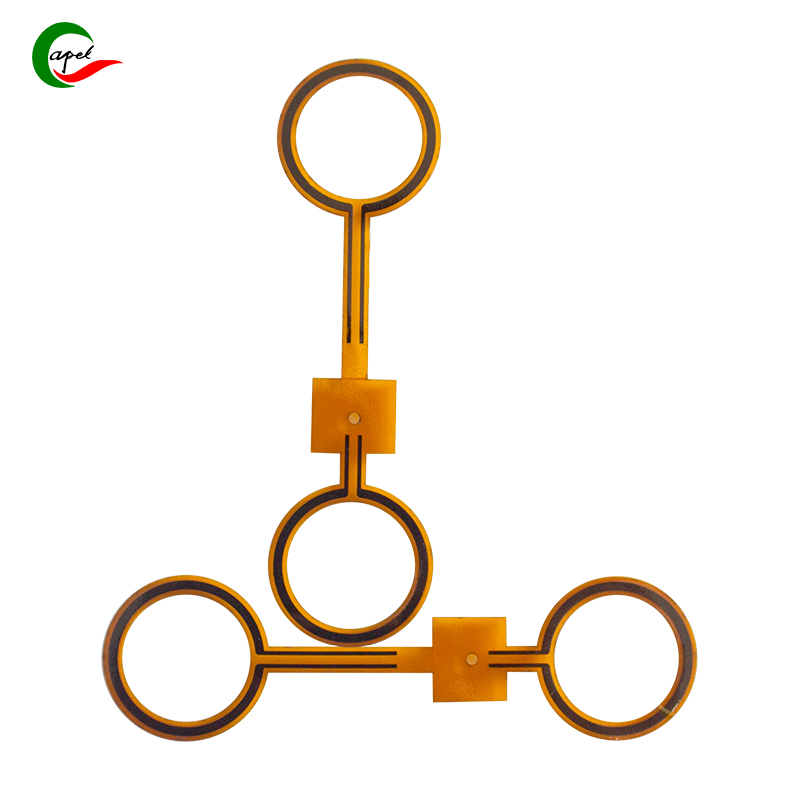

Flexible circuit boards need to use special materials such as polyimide (PI) and polyester (PET) to ensure their flexibility and durability. A reliable manufacturer should be able to select appropriate materials according to the product's application environment (such as temperature, humidity, and chemical resistance) and ensure the compatibility of various materials.

The bending performance is the core characteristic of flexible circuit boards. It should be able to withstand repeated bending without damage. Manufacturers need to conduct strict bending tests and fatigue resistance tests to ensure that the products can meet the application requirements in different scenarios.

Flexible circuit boards often need to be assembled with other components such as connectors and chips. A manufacturer with strong assembly and integration capabilities can ensure the reliability and stability of the entire product, reducing the risk of failure in the later stage.

Choosing a reliable FPC manufacturer requires comprehensive consideration of qualifications, technical capabilities, production equipment, delivery time, and after - sales service. When evaluating the production capabilities of multilayer PCBs and flexible circuit boards, attention should be paid to indicators such as layer count, line width and spacing, hole making technology, material selection, bending performance, and assembly capabilities. Only by selecting a manufacturer that meets the requirements can we ensure the quality and performance of the products and lay a solid foundation for the success of the project.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.