Date: 2025-10-11

When you're designing a flexible PCB that might face heat - whether from environmental conditions or internal components - the substrate material choice becomes critical. Having worked with both PI and PET materials across various industries, I've seen how this single decision can make or break a product's reliability.

Understanding the Core Materials

Let me share what I've learned about these two fundamentally different materials:

Polyimide (PI) - The Workhorse

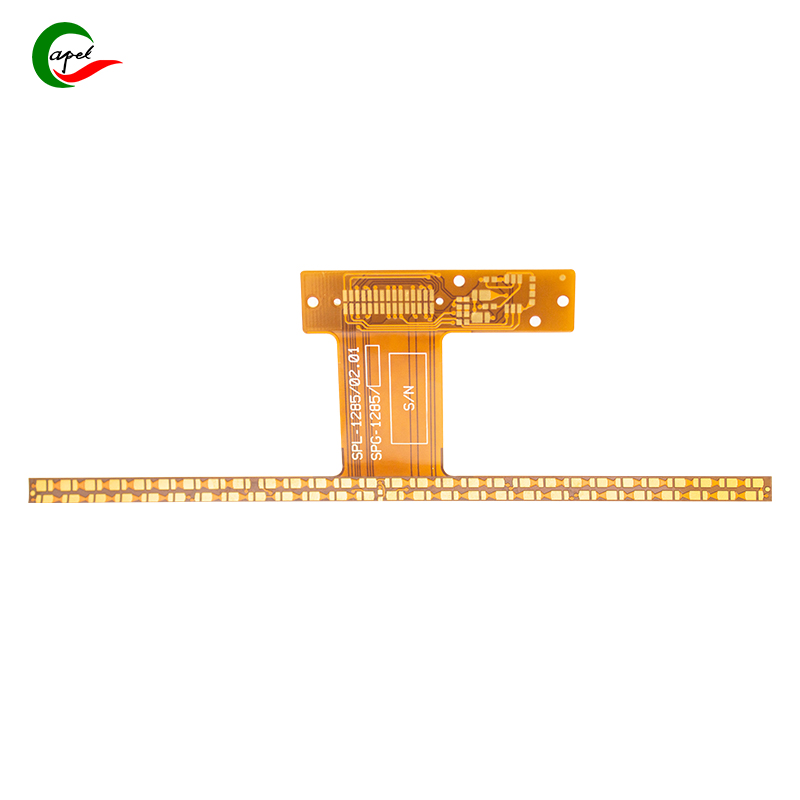

PI substrates feel different from the moment you handle them. There's a certain toughness to that amber-colored material that hints at its capabilities. I remember my first project using PI - we were designing a flexible connection for an automotive transmission sensor, and the material's inherent stability under heat immediately stood out.

The key advantage that keeps bringing engineers back to PI is its incredible temperature range. I've tested PI boards that operated reliably from cryogenic temperatures up to 260°C continuous. This isn't just theoretical - I've seen PI-based flex circuits in industrial ovens that lasted for years where other materials would have failed in months.

PET - The Cost-Effective Alternative

PET feels more pliable and comes in clearer films. In applications like simple LED lighting or consumer electronics where temperatures stay moderate, PET offers significant cost savings. I recently worked on a budget wearable device where PET provided the perfect balance of flexibility and affordability.

However, PET's temperature limitations are very real. I learned this lesson early when a batch of PET-based keyboard flex circuits started warping after being left in a hot car. The material simply couldn't handle the sustained 80°C+ temperatures.

Temperature Performance: Real-World Implications

PI's Thermal Capabilities

What makes PI remarkable isn't just its high temperature tolerance, but how it maintains performance at those temperatures. In automotive under-hood applications, I've specified PI for sensors that need to withstand 150°C continuous operation while maintaining circuit integrity. The material doesn't just survive - it remains stable.

The soldering process itself demonstrates PI's advantage. While PET boards require special low-temperature processes, PI handles standard reflow soldering without issue. This manufacturing benefit alone often justifies the higher material cost.

PET's Thermal Limits

PET's glass transition temperature around 70-80°C represents a hard boundary. Beyond this point, the material begins to soften and lose dimensional stability. I've encountered situations where PET circuits in display applications failed because nearby components pushed temperatures just slightly beyond this threshold.

The degradation isn't always immediate. In one case, PET-based touch sensors developed intermittent failures after six months of operation at what we thought was a safe 65°C. The sustained heat gradually affected the material properties.

Making the Right Choice for Your Application

When PI is Non-Negotiable

Any application involving soldering, high-power components, or elevated environmental temperatures needs PI. Industrial equipment, automotive systems, and aerospace applications almost always require PI. The extra cost becomes insignificant compared to the reliability gained.

Where PET Makes Sense

For consumer electronics operating at room temperature, PET often provides adequate performance at much lower cost. Simple interconnects, basic sensors, and disposable electronics can benefit from PET's economic advantages.

Beyond Temperature: Other Critical Factors

Chemical Resistance Matters

In industrial environments, I've seen PI withstand exposure to oils, solvents, and cleaning agents that would destroy PET. This chemical resilience often proves as valuable as the thermal performance.

Mechanical Longevity

While both materials offer good flexibility, PI typically withstands more bend cycles before failure. For applications like folding phones or repeatedly flexing connections, this durability justifies the premium.

Cost Considerations

The price difference isn't trivial - PET can be 30-50% cheaper than PI. However, I always caution clients to consider total cost of ownership. A failed PI circuit in a medical device or automotive system costs far more than the initial material savings.

Practical Implementation Insights

From my experience, successful material selection involves:

Understanding Real Operating Conditions

Don't just look at maximum temperatures - consider thermal cycling, mechanical stress, and environmental factors. I often recommend installing temperature loggers in prototype devices to capture real-world conditions.

Manufacturing Considerations

PI's thermal stability simplifies production, while PET requires careful process control. Factor in these manufacturing differences when comparing total cost.

Testing Under Actual Conditions

I always advise clients to conduct accelerated life testing that replicates their specific use case. Theoretical specifications don't always predict real-world performance.

The choice between PI and PET ultimately comes down to understanding your application's true requirements and being honest about the trade-offs. While PI offers superior performance, PET provides economic advantages in appropriate applications. The key is matching the material to the actual operating environment rather than defaulting to familiar choices.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..