Date: 2025-12-05

Let's be clear: a rigid flex PCB is not a commodity. You can't just pick a part number from a catalog, compare three quotes on price, and place an order. Treating the manufacturer of this sophisticated component as a simple "vendor" is like treating a master watchmaker as a "screwdriver salesman"—you're missing the entire point of their expertise.

A true rigid flex PCB partner co-owns the reliability of your product. What they provide isn't just a board; it's a guarantee of manufacturability, a shared risk, and an endorsement of your end product's performance. Need your device to survive 100,000 bends in a harsh environment? That promise isn't fulfilled by your design alone. It's fulfilled through your manufacturing partner's deep competence in process, materials, and quality control.

When evaluating suppliers, look beyond price and basic specs. Probe into how they tackle these core challenges:

Mastery Over Material Consistency

The flexible sections often use polyimide (PI). But not all PI is equal: there's standard commercial grade, high-Tg (glass transition temperature) grade for heat, and ultra-high flex endurance grade. A seasoned partner won't wait for your specification. Instead, they will proactively recommend and source the optimal material based on your application (Is it a one-time static bend or a daily dynamic fold in a smartwatch hinge? What's the operating temperature?). They should provide batch reports and certifications (like UL 94 V-0) for their materials.

Specialized "Transition Zone" Craftsmanship

Where the rigid FR-4 meets the flexible PI is the most critical and vulnerable stress point. Top-tier manufacturers own proprietary processes here:

Lamination Process: Precise control of temperature, pressure, and time to ensure zero delamination or voids when bonding multiple layers.

Coverlay & Plating: Expertise in applying protective films with strong adhesion and ensuring plating integrity in holes survives repeated flexing without cracking.

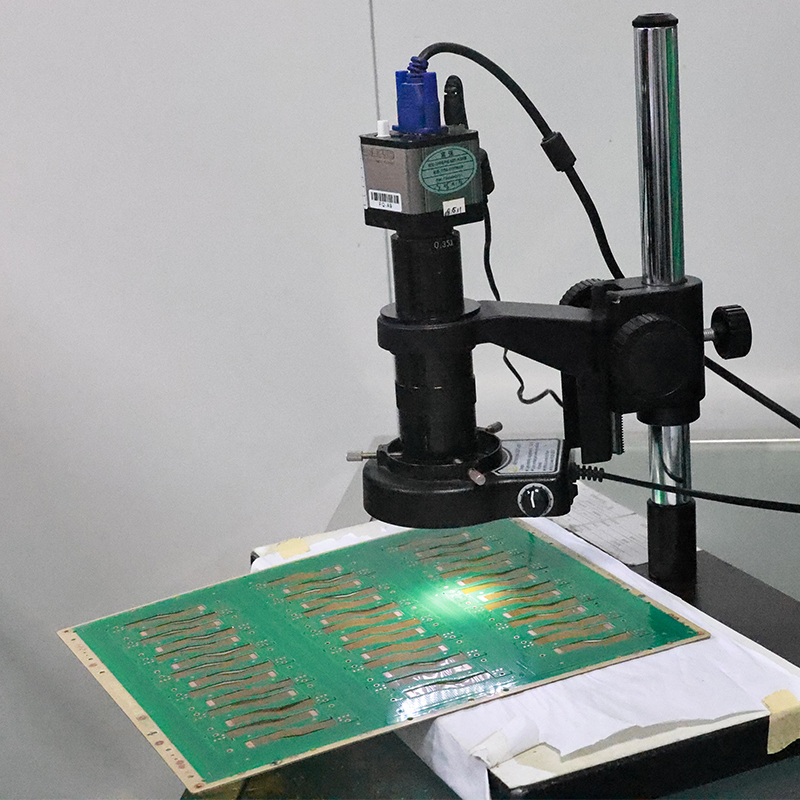

They should be able to show you microsection analysis reports—microscope images that prove the integrity and uniformity of their transition zones.

Quality Control That Goes Far Beyond "Power-On"

For standard PCBs, quality might mean a simple electrical test. For rigid flex, that's grossly inadequate. A professional supplier employs a multi-dimensional quality regime:

Mechanical Reliability Testing: Sampling for flex testing (e.g., per IPC-6013), simulating real-world cycles, followed by electrical and physical inspection.

Environmental Stress Testing: Conducting thermal shock cycling (e.g., -40°C ~ 125°C) to verify the bond survives differing material expansion rates.

In-Process Monitoring: Using Automated Optical Inspection (AOI) for fine traces and X-ray inspection for layer alignment and internal defects.

In electronics manufacturing, there's a fundamental difference between a supplier with its own factory and one that relies on sub-contractors or trading. For complex components like rigid flex PCBs, this difference translates directly into control, transparency, and responsiveness for your project.

Complete Control, No Black Boxes: At Kaboer's owned facility, every step—from engineering review, material storage, to each production process (cutting, laser drilling, plating, lamination, etching, finishing, testing)—happens under one roof and one management system. This means your order status, process parameters, and any issues are tracked and coordinated in real time, with no communication gaps or finger-pointing between middlemen.

Rapid Response & Agile Adjustments: When your project needs a change or faces an urgent request, our short internal decision chain is key. Our production, engineering, and quality teams can huddle quickly, assess feasibility on the spot, and adjust the schedule immediately—a level of agility impossible for brokers dependent on external factories.

Accumulated Expertise in Technology & Process: All the complex know-how, equipment tuning experience, and failure analysis data are accumulated within our own walls. This tacit knowledge, which never appears on a quote, directly ensures stable yield and long-term reliability. Our engineers solve problems on their own production lines, so their advice is grounded in firsthand practice.

At Kaboer, we understand we are building more than circuits; we are building the foundation of your product's success. We specialize in transforming your proven designs into consistent, reliable, and durable physical components. Our core value is pure manufacturing expertise:

DFM Feedback & Fast In-House Validation: Before production, our engineering team reviews your design files against our established Process Design Rules. With our own factory, we can quickly run internal process validation boards to test critical design features (like unique bends or high-density interconnects), providing data-backed recommendations, not just theory.

Transparent and Traceable Production: From every roll of PI material to the finished board, we maintain full traceability. You can trace any board back to its production batch, material lots, and key process parameters.

Reliability Data Beyond Spec Sheets: We provide customized Reliability Verification Reports for critical projects, including test data from bend cycling or thermal shock on your specific samples, giving you confidence through evidence.

Our Open Invitation: Seeing is Believing We believe trust is built on transparent, in-person verification. We extend a standing invitation to you—whether a potential client in the evaluation phase or a valued existing partner—to schedule a visit to our owned factory in China. See for yourself:

The environment and equipment where your product will be made.

How our engineering and production teams collaborate to solve issues.

Our well-maintained cleanrooms, precision inspection tools, and standardized workflows.

Meet our management and technical experts face-to-face for in-depth discussions.

Move past generalities. Ask potential partners these specific questions. Their answers will quickly reveal their caliber:

"Can you show me a case study for a similar application (e.g., dynamic flex / high-temperature) and detail the specific processes used?"

"For the rigid-to-flex transition zones in my design, what specific lamination and reinforcement processes will you use to ensure reliability?"

"Beyond electrical test, what standard and optional reliability testing do you perform on rigid flex boards? Can I see a sample report?"

"Are we able to tour your production facility to see key processes like lamination and AOI firsthand?"

"If a material or process-related yield issue arises, what is your root cause analysis and corrective action process?"

Choosing a rigid flex PCB supplier is choosing a "co-founder" for the manufacturing phase of your product.

If you are looking for a partner who deeply understands rigid flex manufacturing, owns its factory for complete control, and is transparent enough to welcome your inspection, Kaboer is ready. We invite you to test us with your toughest technical questions and, more importantly, to see our operations in person. Let's start with a practical conversation about your specific project needs and manufacturing challenges.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..