Common Defects in FPCs: What Can Go Wrong and Why They Matter

Date: 2025-08-15

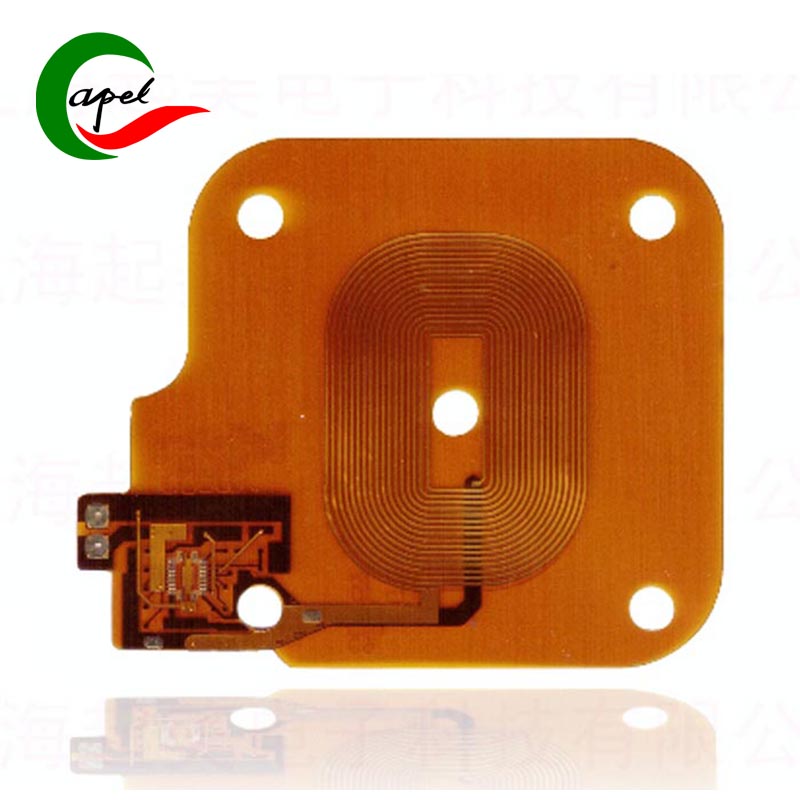

Flexible Printed Circuits (FPCs) are marvels of engineering, bending and flexing to fit into the slimmest gadgets. But their complexity—thin materials, tiny traces, and delicate layers—makes them prone to specific flaws. Let’s shine a light on the most common defects, why they happen, and how they affect your devices.

1. Copper Trace Damage: The “Roads” of Electricity Get Blocked

Copper traces are the highways that carry electrical signals through an FPC. When they’re damaged, the whole circuit suffers:

- Scratches or breaks: Even a tiny nick from a sharp tool during assembly can cut a trace, stopping electricity in its tracks. Imagine a road with a gap—cars (signals) can’t pass.

- Over-etching: During manufacturing, if too much copper is removed, traces become thin and weak, like a thread stretched too tight. They might break when the FPC bends, causing devices to flicker or shut down.

2. Adhesion Failures: Layers That Come Unglued

FPCs are made of layers—polyimide film, copper, and cover layers—held together by adhesives. When these layers separate:

- Bubbles form: Air gets trapped between layers, creating bumps. In a smartwatch FPC, this can push against the screen, causing display glitches.

- Peeling edges: The cover layer (which protects copper) starts to lift, exposing traces to dust and moisture. Over time, this leads to corrosion and short circuits—like a bandage falling off a cut.

3. Solder Joint Issues: Weak Links in the ChainSolder joints connect FPCs to components like chips or connectors, but they’re easy to mess up:- Cold solder joints: If the solder doesn’t melt properly, it forms a rough, brittle bond. It might work at first, but a small bump (like dropping your phone) can break it, leading to sudden failures.

- Solder bridges: Excess solder creates a bridge between two traces, short-circuiting them. It’s like a wire crossing another—electricity takes a wrong turn, frying components.

4. Cover Layer Defects: Holes in the Armor

The cover layer shields copper traces, but flaws here leave them vulnerable:

- Pinholes: Tiny holes in the cover layer let moisture or dirt reach copper, causing rust-like oxidation. In a fitness tracker, sweat seeping through can ruin the circuit.

Misalignment: If the cover layer isn’t positioned correctly, it might cover solder pads (where components connect), making assembly impossible—like a sticker covering a keyhole.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.