Date: 2025-10-25

Here's a common issue engineers face when working on autonomous driving platforms: as you pack more electronic modules into the vehicle, their wiring starts talking over each other. This electromagnetic interference becomes more than just noise - it can scramble the data between sensors and controllers that keeps the vehicle aware of its surroundings.

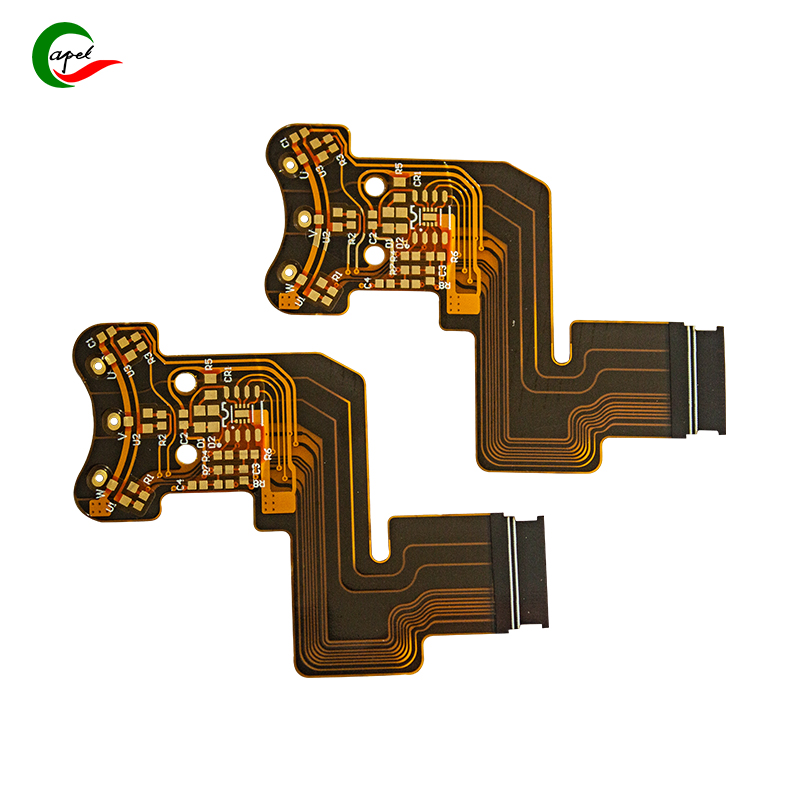

The conventional approach of adding external shielding works to some extent, but it takes up space and adds complexity. What we're doing differently is building the shielding right into the flexible PCBs that connect these systems. Instead of wrapping protection around the circuitry, we make the protection part of the circuitry itself.

Here's how this plays out in practical terms:

The shielding layer - typically a specialized metallic material - gets integrated during the board manufacturing process. This creates a built-in barrier that either blocks or redirects electromagnetic waves before they can interfere with signal transmission. The flexible nature of the boards means they can be routed through tight spaces between modules while maintaining this protection consistently.

What we've observed in testing is that this approach delivers cleaner signals between critical systems like LiDAR sensors and their processing units. The data arrives with less distortion, which translates to more reliable perception and decision-making for the autonomous system.

From a design perspective, this integrated shielding approach offers multiple advantages. It reduces the need for additional shielding components that would otherwise add weight and require more installation space. The manufacturing process becomes more streamlined too, since you're dealing with a single component that provides both connectivity and protection.

The durability aspect matters significantly in automotive applications. Unlike external shields that can work loose over time, the embedded shielding maintains its integrity even under continuous vibration and temperature cycling. This consistent performance is crucial for systems that must operate reliably over the vehicle's entire lifespan.

For engineering teams working on autonomous platforms, this represents a practical solution to a persistent challenge. By addressing EMI at the circuit board level rather than through after-the-fact mitigation, we're seeing more robust system architectures with fewer signal integrity issues during validation testing.

The technology aligns well with the industry's move toward more integrated electronic systems. As autonomous functionality continues to evolve, having clean, reliable communication between vehicle modules becomes increasingly critical. This built-in shielding approach provides that foundation while accommodating the physical constraints of modern vehicle designs.

What we're ultimately talking about is building more resilience into the nervous system of autonomous vehicles. When every signal matters, the quality of the pathways carrying those signals becomes just as important as the components generating them.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..