Date: 2025-10-25

In modern vehicle systems, we're seeing an unprecedented density of electronic components. From front-facing cameras to ultrasonic sensors and radar modules, these systems generate massive amounts of data that need to travel through complex pathways to reach processing units. The challenge isn't just about moving data - it's about maintaining signal quality throughout the journey.

This is where conventional rigid PCBs often fall short. Their material properties create inherent limitations for high-frequency signals, leading to the signal degradation issues that engineers frequently encounter in automotive applications. The further a signal has to travel through suboptimal materials, the more pronounced these problems become.

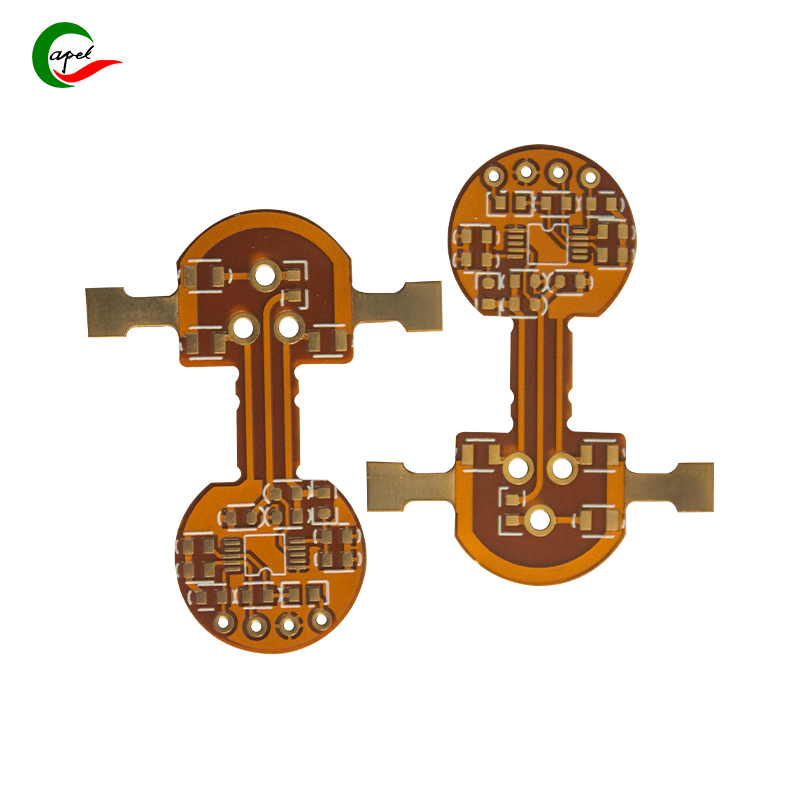

Our approach focuses on two fundamental aspects: material science and mechanical design. The low-dielectric substrates we utilize aren't just marginally better than standard materials - they represent a different category of performance. By fundamentally reducing the material's interaction with electrical fields, we minimize both signal loss and cross-talk between adjacent traces. This becomes increasingly critical as data rates continue to climb in modern ADAS applications.

The flexibility aspect goes beyond simply being bendable. It's about enabling three-dimensional packaging solutions that were previously impossible. Instead of designing around the limitations of rigid boards, engineers can now route circuits through the available spaces in vehicle architectures. This means sensors can be placed where they're most effective rather than where the circuitry can most easily reach.

What often gets overlooked is how these two advantages work together. When you reduce signal loss through better materials, you can tolerate longer signal paths. When you have flexible form factors, you can create more direct routing. Combine both, and you get a synergistic effect that substantially improves overall system performance.

The manufacturing process deserves special mention too. Proper lamination isn't just about sticking layers together - it's about creating a unified structure that maintains its electrical properties while withstanding automotive environmental challenges. We've seen temperatures ranging from -40°C to over 125°C in different vehicle locations, not to mention constant vibration and mechanical stress. The construction method matters as much as the materials themselves.

From a practical standpoint, this technology impacts several aspects of vehicle design:

It reduces the need for signal conditioning components and repeaters

It allows for more compact electronic packaging

It improves system reliability by eliminating points of failure

It simplifies waterproofing and sealing challenges

It enables more modular approaches to electronic systems

The automotive industry's transition toward more autonomous functionality makes these considerations increasingly important. As safety systems become more dependent on sensor data, the reliability of that data becomes non-negotiable. We're not just talking about convenience features anymore - we're discussing systems where signal integrity directly impacts vehicle safety.

For engineers working on these systems, the message is simple: the pathway matters as much as the endpoints. The choice of circuit materials and form factors isn't just a minor implementation detail - it's a fundamental architectural decision that can determine the success or failure of an entire vehicle electronic system.

What we're offering isn't just a different type of circuit board - it's a different approach to thinking about signal transmission in constrained environments. The results speak for themselves: cleaner signals, more reliable systems, and ultimately, safer vehicles.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..