Introduction

Flexible PCBs have emerged as a quiet revolution in automotive electronics, reshaping how modern vehicles manage power, data transmission, and connectivity. With their unique ability to bend, twist, and fit into tight, irregular spaces, they perfectly align with the demands of today’s cars—packed with more technology than ever before.

Infotainment Systems: Seamless Connectivity in Compact Spaces

In-car infotainment systems rely heavily on flexible PCBs to integrate various components. They connect touchscreens, speakers, navigation modules, and control buttons, snaking through the curved contours of dashboards and center consoles. By replacing bulky, rigid wiring harnesses, they reduce overall vehicle weight—a critical factor for improving fuel efficiency and extending electric vehicle (EV) range.

Advanced Driver-Assistance Systems (ADAS): Reliable Data Flow for Safety

ADAS, the backbone of modern vehicle safety, depends on uninterrupted data transmission between cameras, radar, LiDAR, and onboard computers. Flexible PCBs excel here: they bend around door frames, tuck behind bumpers, and fit into tight gaps near windshields, ensuring signals flow without loss. Their durability against vibration and temperature changes also guarantees consistent performance, which is vital for functions like automatic emergency braking and lane-keeping assist.

Electric and Hybrid Vehicles: Optimizing Battery Performance

EVs and hybrids benefit significantly from flexible PCBs, especially in battery management systems (BMS). These systems monitor individual battery cells to ensure balanced charging, prevent overheating, and extend battery life. Flexible PCBs fit into the narrow spaces between battery packs, withstanding high temperatures and constant thermal expansion—challenges that rigid PCBs struggle to overcome.

Basic Vehicle Functions: Durability in Everyday Use

Beyond high-tech systems, flexible PCBs enhance even basic car functions. They power seat adjustment controls, adaptive lighting (like LED headlights), and climate control sensors. Their resistance to temperature swings—from freezing winters to scorching summers—and ability to handle repeated movement (such as seat adjustments) ensures long-term reliability, reducing maintenance costs for drivers and manufacturers alike.

Conclusion

Flexible PCBs are unsung heroes in automotive innovation, enabling cars to be smarter, lighter, and more efficient. As vehicles grow more connected and electrified, their role in integrating technology seamlessly and reliably will only become more essential.

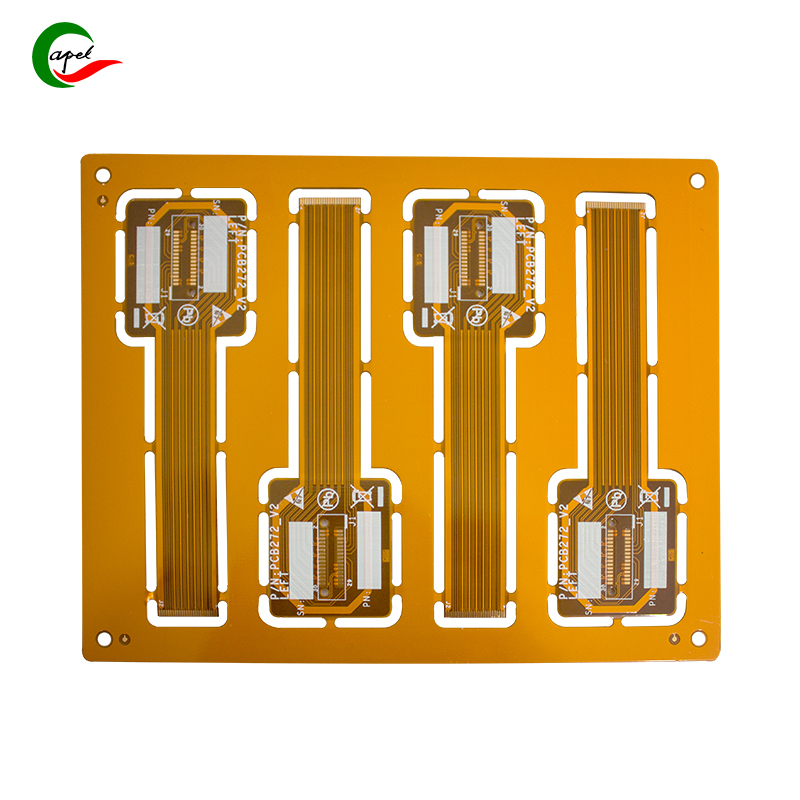

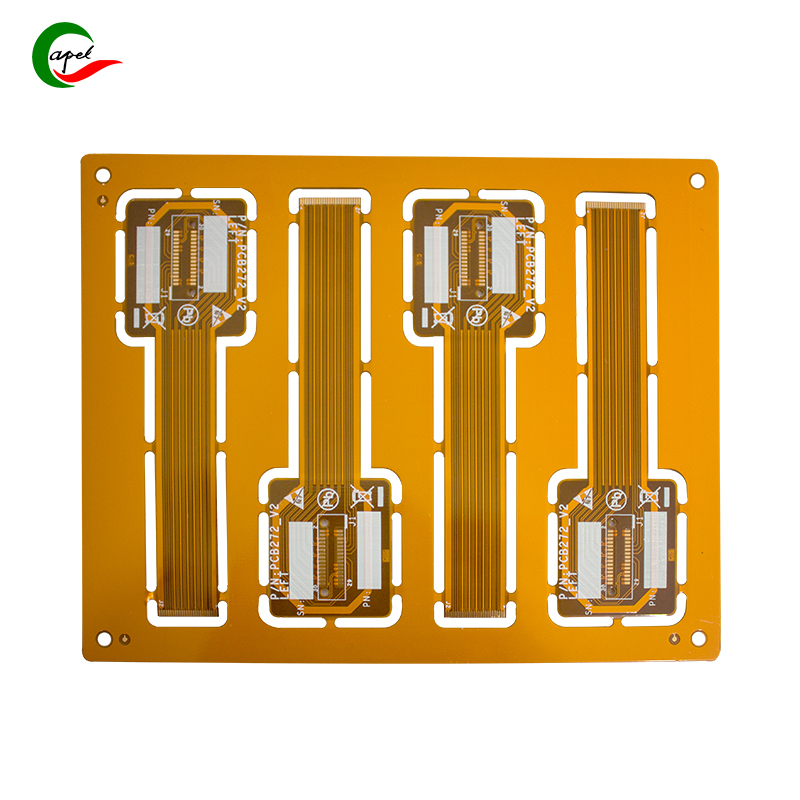

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.