Date: 2026-01-23

Let's start with a problem you might recognize. Your design team has a brilliant concept for a new wearable device, a compact sensor, or a product with a moving hinge. The electronics are mapped out, but there’s a physical snag: the housing is an irregular shape, components are in the way, and a traditional rigid PCB simply won't fit without making the entire device bulkier. You're stuck choosing between a compromised layout or a larger case.

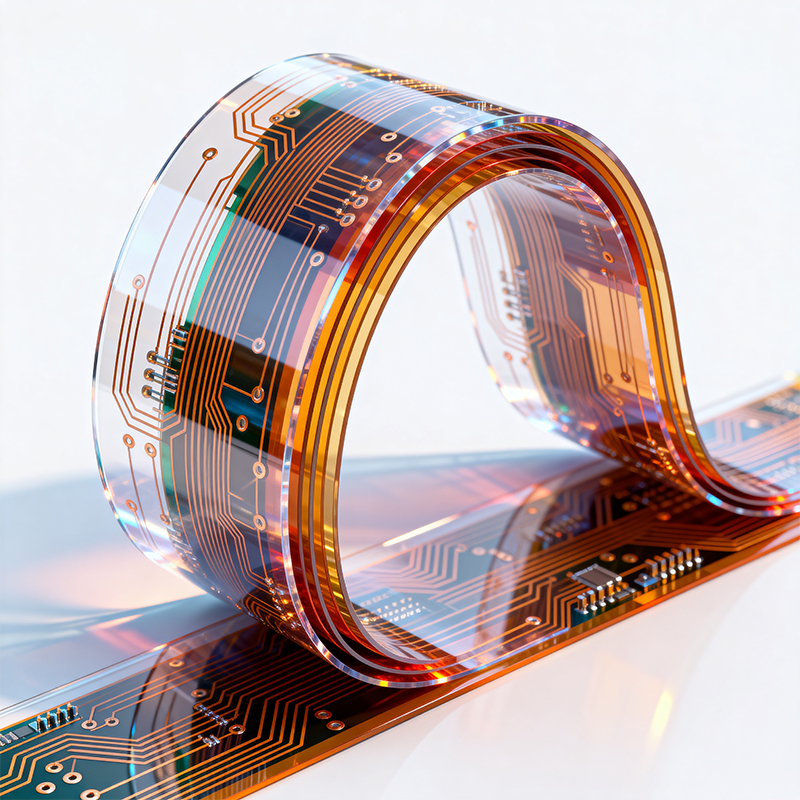

There's a third path, one that transforms a limitation into an advantage: the Flexible Printed Circuit (FPC).

It's more than just a "floppy PCB." An FPC is a precisely engineered electronic interconnect built on a thin, bendable insulating film, most commonly a durable, high-temperature plastic called polyimide. Instead of fiberglass (FR4), this film serves as the foundation for copper traces, creating a circuit that can flex, fold, and twist.

A simple way to picture it:

A standard rigid PCB is like a city map printed on a ceramic tile. It's detailed and permanent, but completely inflexible. Your product's design must conform to its rigid shape.

A Flexible Printed Circuit is like that same city map printed on a durable sheet of rubber. You can roll it up, bend it around corners, or fold it to fit into a small pocket. All the connections (the "streets") remain intact and functional.

Engineers don't use flexible circuits just because they can. They use them because they solve fundamental physical and reliability challenges.

1. Conquer Three-Dimensional Space.

This is the biggest win. An FPC isn't confined to a flat plane. It can be designed to snake through a product's interior, bending over batteries, wrapping around structural elements, or connecting subsystems on different planes. This three-dimensional routing can often reduce the required volume by 30% or more compared to using multiple rigid boards and connectors.

2. Enable and Survive Motion.

Does your product fold, flip, or have a moving part? Wires fatigue, and connectors wear. A flexible circuit, designed with a specific bend radius and dynamic flexing in mind, can be engineered to withstand hundreds of thousands of bending cycles. It's the hidden, reliable workhorse inside every flip-style smartphone and laptop hinge.

3. Achieve Extreme Weight and Thickness Savings.

Polyimide film is remarkably thin and light. Replacing a rigid board, connector, and wire harness with a single, integrated FPC dramatically cuts weight and minimizes profile. This is critical in aerospace, advanced wearables, and any application where every gram and millimeter counts.

4. Boost Reliability by Reducing Connections.

Every connector is a potential failure point—susceptible to corrosion, vibration, and mating issues. A well-designed FPC creates continuous, solderless connections between points, leading to a more robust system, especially in harsh environments.

The magic isn't just in the design; it's in the materials.

Polyimide Film: This isn't ordinary plastic. It can withstand the high temperatures of solder reflow (up to 260°C/500°F+) without degrading, resists chemicals, and has excellent electrical insulation properties.

Specialized Copper: The copper foil used is typically rolled annealed copper, which has a long, grain structure that makes it far more resistant to cracking from repeated bending than the copper used on standard PCBs.

Switching to flex isn't as simple as making your rigid board layout thinner. It requires specific design rules:

Bend Radius: You must define how tightly the circuit can bend without damaging the copper traces. A rule of thumb is a minimum radius of 6-10 times the circuit's thickness.

Neutral Axis: Traces should be routed in the layer that experiences the least stress during bending to maximize flex life.

Stiffeners: Areas where components are soldered often need rigid reinforcements (made of FR4 or metal) to provide stability during assembly and use.

Transition Zones: The points where the circuit transitions from rigid to flexible or where it bends require careful geometric design to prevent stress concentration.

Fabricating and assembling flexible circuits is a delicate art that demands precision and specialized equipment.

Fabrication: It involves precise imaging and etching of copper on thin film, followed by laminating protective cover layers. Laser cutting is often used to create intricate outlines.

Assembly (The Critical Challenge): You can't just run a flimsy piece of polyimide through a standard SMT line. It requires:

Custom Carriers & Fixtures: To hold the flexible circuit perfectly flat and stable during solder paste printing and component placement.

Tailored Process Parameters: Reflow oven profiles must account for the different thermal mass and expansion properties of the thin film.

Expert Handling: From depaneling to testing, every step needs to account for the circuit's flexibility.

From everyday gadgets to specialized equipment, FPCs are everywhere:

Consumer Tech: Connecting displays to main boards in smartphones/tablets; inside cameras, wearables, and foldable devices.

Automotive: Throughout modern cars—in dashboard clusters, seat controls, sensor systems, and LED lighting.

Medical: In hearing aids, endoscopic tools, and wearable monitors where size, reliability, and conformity are critical.

Industrial & Aerospace: In robotics, satellite assemblies, and equipment where vibration resistance and tight packaging are non-negotiable.

This is the crucial point. Successfully implementing a flexible printed circuit is less about purchasing a component and more about engaging a guide for a specialized journey. The gap between a functional design and a reliable, manufacturable product is bridged by experience.

This is the integrated value a partner like Kaboer provides. With our own factory in Shenzhen, we don't just see an order for boards; we see a 3D puzzle to solve in collaboration with you.

What this means for your project:

Early-Phase Design Partnership: Our engineers can review your mechanical and electrical goals together. Is this a static bend (folded once during assembly) or a dynamic flex (moving thousands of times)? We provide actionable feedback on stack-up, material choice, and layout to ensure reliability from the very first sketch.

Seamless Process Integration: Because we control both fabrication and assembly, we identify potential manufacturing hurdles early. We can advise on stiffener placement, folding sequences, and how the design will behave in your assembly line.

Built for Delicate Work: Our SMT lines are equipped with the specialized tooling and process knowledge needed to assemble flexible substrates with high yield and consistent quality.

The Shenzhen Ecosystem, Simplified: Being at the heart of the global electronics supply chain gives us direct access to the best materials and components. We manage that complexity, offering you a reliable, cost-effective supply path without the logistical overhead.

Embracing Flexible Printed Circuit technology is a commitment to superior product design. It transforms electronics from a component you must accommodate into an element that actively enables innovation in form, function, and reliability.

The most successful outcomes come from treating it as a collaborative endeavor—marrying your vision for the product with our expertise in making it manufacturable. It’s about working with a partner who understands both the "why" and the "how."

If your next design is pushing against the limits of space, weight, or motion, let's discuss not just how to build a circuit, but how to build the right foundation for what you're creating.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..