Date: 2026-01-23

Let’s be honest—most of the time when you think about a printed circuit board (PCB), you're thinking about the electronics: the traces, the chips, the soldered connections. But sometimes, the most critical part of getting your product assembled isn't an electronic component at all. It's a simple mechanical feature: a hole for a screw.

And not just any hole. If you've ever struggled with a screw head that sticks up awkwardly, prevents a board from sitting flush, or creates a short-circuit risk, you've encountered a problem that a counterbore hole is designed to solve.

Think of it like this: You're mounting a shelf to a wall. A standard screw and washer leave a small bump on the surface. But if you counterbore the hole in the shelf—carving out a little pocket—the screw head can sink down below the surface, leaving everything smooth and flush. A counterbore hole on a PCB does exactly the same thing, just on a much more precise scale.

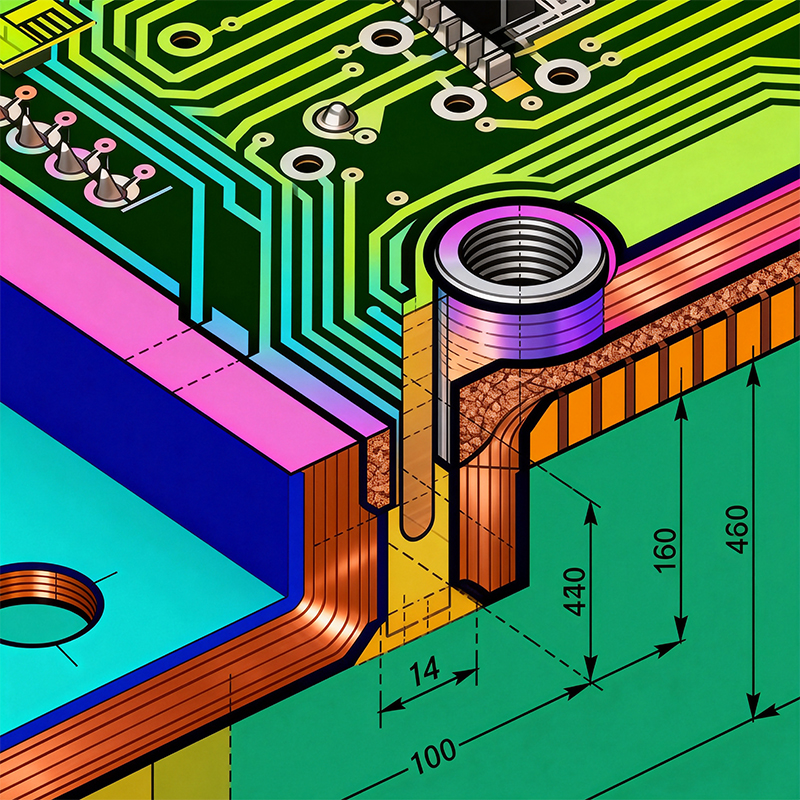

A counterbore hole is a two-step cylindrical hole. It consists of:

A smaller pilot hole that goes all the way through the material.

A larger, shallower cavity drilled or milled on top of it, at the surface.

This larger top cavity has a flat bottom and is designed to house the head of a fastener (like a socket head cap screw) so that it sits entirely below the surface of the board.

The key difference between a counterbore and a similar-looking feature called a countersink is the shape at the bottom. A countersink has a conical, tapered seat for flat-head screws. A counterbore has a flat, cylindrical seat for screws with a flat underside. You choose one based on the screw type you're using.

A bare circuit board is rarely the final product. It needs to be mounted securely inside an enclosure, attached to a heatsink, or connected to another assembly. Here’s where the counterbore becomes your best friend:

For a Clean, Flush Mount: This is the primary reason. By sinking the screw head below the PCB surface, you ensure the board sits perfectly flat against its mounting surface. This is crucial for optimal thermal contact with a heatsink or for fitting into a tight, slim enclosure.

To Eliminate Electrical Short Hazards: A protruding metal screw head is a disaster waiting to happen on a board packed with components and traces. Sinking it into a counterbore creates a safe, recessed pocket, greatly reducing the chance it will accidentally touch and short out neighboring circuits.

For Secure Stacking or Spacing: In board-stacking configurations, a counterbore allows you to use a standoff or a screw of a specific length to precisely control the gap between two boards. The screw head stays contained within its pocket.

Professional Fit and Finish: It simply looks and functions more professionally. There are no wobbly boards or awkward protrusions. Everything fits together as intended by the design.

If you're specifying a counterbore hole on your PCB fabrication drawings, clarity is everything to avoid costly mistakes. Your manufacturer needs to know:

The Final Hole Size (Pilot Hole Diameter): This is the diameter of the smaller through-hole. It must match the shaft size of your screw with a small clearance.

The Counterbore Diameter: This must be larger than the diameter of your screw head.

The Counterbore Depth: This is critical. It must be slightly deeper than the height of your screw head to ensure it sits completely below the surface, but not so deep that it weakens the board or breaks into inner copper layers.

Engineers typically call these out in a format like: ∅6.0mm CBORE x 3.0mm DEEP on ∅3.2mm THRU HOLE. Clear communication prevents the fab shop from guessing.

This is where the choice of PCB manufacturer matters. Creating a counterbore isn't part of the standard etching or drilling process for circuitry. It’s a secondary mechanical machining operation.

After the primary PCB fabrication is complete, a separate CNC milling machine or a specialized drill bit with a stop is used to accurately mill out the cylindrical pocket. This requires precise control of depth and location.

A factory that only does high-volume, simple consumer boards might not have this capability or might treat it as an expensive special request. A manufacturer like Kaboer, with our own factory in Shenzhen equipped for complex and mixed-technology builds, handles these features routinely. Our engineering team can review your mechanical drawings alongside your circuit files to ensure the counterbores are placed correctly (away from critical traces and components) and can be manufactured reliably without affecting the board's integrity.

The counterbore hole is a perfect example of how electronic and mechanical design must work hand-in-hand. It’s a small, often overlooked feature that solves very practical problems of assembly, safety, and professionalism.

When your product design calls for a secure, flush-mounted PCB, specifying a correctly designed counterbore is a mark of thoughtful engineering. And partnering with a manufacturer that understands both the electrical and mechanical requirements of your board is the key to turning that thoughtful design into a perfectly realized physical product. After all, the best circuit in the world is useless if you can't mount it properly inside your device.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..