Imagine a startup launching a smartwatch—only to recall 10,000 units because the FPC (Flexible Printed Circuit) they chose couldn’t handle wrist bending. Or an automotive supplier delaying production because their FPC failed to withstand engine heat. Choosing the right FPC isn’t just about picking a “flexible circuit”—it’s about matching the FPC to your product’s unique needs.

FPCs power everything from AirPods to electric vehicles, but no single FPC works for all. A wearable device needs a thin, lightweight FPC; a car’s engine bay needs one that resists high temperatures. The key is to start with your application, then narrow down by performance. Below is a step-by-step guide to avoid costly mistakes.

Your product’s use case determines 70% of your FPC choice. Here are 3 common scenarios and their FPC requirements:

- Needs: Ultra-thin (≤0.1mm), lightweight, and able to bend 10,000+ times.

- Recommended FPC: Single-layer or double-layer FPC with polyimide substrate (flexible, thin). For example, Apple’s AirPods use a 0.08mm single-layer FPC—small enough to fit in the earbud and flexible enough to handle tiny movements.

- Avoid: Thick multi-layer FPCs—they’re too bulky and heavy for wearables.

- Needs: High-temperature resistance (-40°C to 125°C), vibration resistance, and chemical resistance (to oil/fuel).

- Recommended FPC: Multi-layer FPC with glass-reinforced polyimide (GRPI) substrate. Tesla uses this type in its engine sensors—they survive engine heat and road vibrations for 10+ years.

- Avoid: Standard polyimide FPCs—they melt or crack in high temperatures.

- Needs: Biocompatibility (safe for contact with skin/tissues), ultra-flexible (to bend in tight spaces), and sterilization resistance (to survive autoclaving).

- Recommended FPC: Single-layer FPC with medical-grade polyimide and gold-plated traces (biocompatible). Medtronic’s glucose monitors use this FPC—they’re flexible enough to fit under skin and safe for long-term use.

- Avoid: FPCs with lead or toxic adhesives—they’re unsafe for medical use.

Once you’ve aligned with your scenario, check these 5 non-negotiable parameters:

- Polyimide (PI): The most common—flexible, heat-resistant (up to 200°C), and good for most consumer/automotive uses.

- Polyester (PET): Cheaper but less heat-resistant (max 120°C)—only use for low-temperature products (e.g., basic fitness trackers).

- GRPI: Glass-reinforced PI—stiffer than PI but more heat/vibration-resistant—ideal for automotive/industrial use.

Example: A drone maker switched from PET to PI FPCs—their drones now work in hot weather (up to 45°C) without FPC failure.

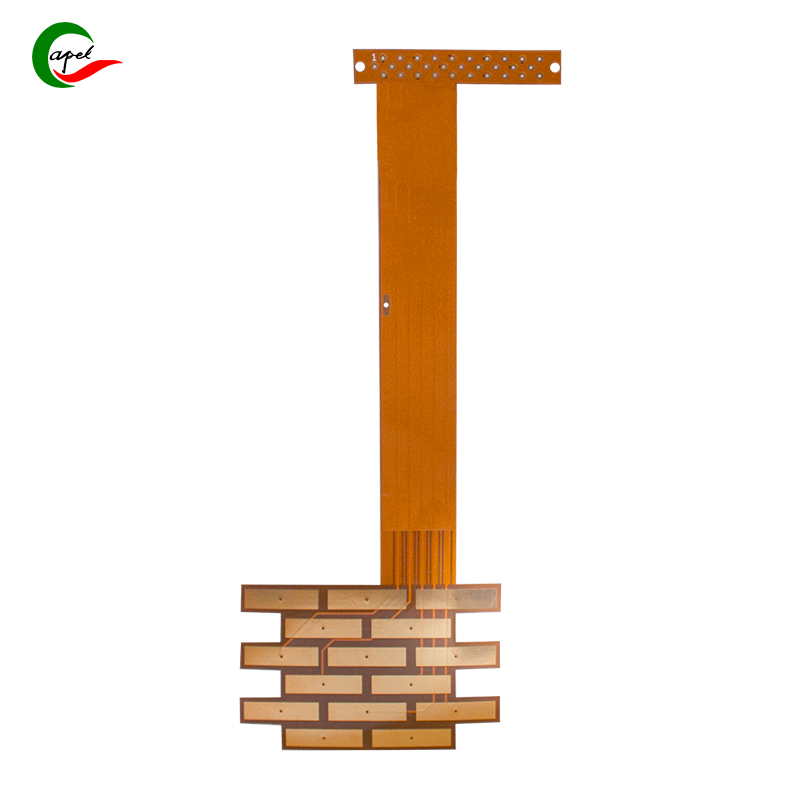

- Single-layer: Thinnest (0.05-0.1mm), cheapest—good for simple connections (e.g., earbud battery to speaker).

- Double-layer: Has traces on both sides (connected via vias)—used for more complex circuits (e.g., smartwatch display to processor).

- Multi-layer (3+): For high-density circuits (e.g., automotive infotainment with multiple sensors)—but thicker and more expensive.

Example: A smartwatch brand upgraded from single-layer to double-layer FPCs—they now fit more traces for health sensors without increasing size.

- Bend Radius: The minimum radius the FPC can bend without cracking (e.g., 3x the FPC thickness is industry standard). A 0.1mm FPC needs a ≥0.3mm bend radius.

- Cycle Life: How many times it can bend (e.g., 10,000 cycles for wearables, 100,000 for foldable phones).

Example: A foldable phone maker tested FPCs with 50,000 vs. 200,000 cycle life—they chose 200,000 to ensure 5+ years of use.

- Copper: The standard—choose thickness based on current (e.g., 1oz copper for low-current wearables, 3oz for high-current automotive parts).

- Gold-Plated Copper: More conductive and corrosion-resistant—use for medical/industrial devices (e.g., endoscopes that contact fluids).

Example: A medical device firm used gold-plated FPCs—they resist corrosion from body fluids, lasting 2x longer than plain copper.

- IP Rating: For water/dust resistance (e.g., IP67 for earbuds that get wet).

- UL Rating: For flammability (e.g., UL94 V-0 for automotive FPCs—they don’t catch fire easily).

Example: A outdoor speaker brand chose IP68-rated FPCs—their speakers work in rain without FPC short circuits.

- Mistake 1: Choosing the cheapest FPC. A fitness tracker brand used cheap PET FPCs—they failed in hot weather, leading to a $50,000 recall.

- Mistake 2: Ignoring bend radius. A drone maker used an FPC with a 0.2mm bend radius (too small for their 0.1mm FPC)—the FPCs cracked during flight.

- Mistake 3: Overlooking certifications. A medical device firm forgot UL medical certification—their FPCs were rejected by regulators, delaying launch by 6 months.

Choosing an FPC isn’t guesswork—it’s about asking: What does my product do? Where will it be used? What stresses will it face? By starting with your application, then checking substrate, layers, bend life, traces, and certifications, you’ll pick an FPC that’s reliable, cost-effective, and built for your product’s unique challenges.

A small electronics brand followed this guide: they needed an FPC for a waterproof fitness tracker, so they chose a single-layer PI FPC (0.1mm, IP68, 10,000 cycle life). Their product launched on time, with zero FPC-related returns. The lesson? The best FPC isn’t the most advanced—it’s the one that fits your needs perfectly.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.