Imagine unfolding your $1,500 foldable phone—only to feel the screen flicker, then go black. Or noticing a tiny crack along the fold after 6 months of use. For foldable phones, the biggest challenge isn’t the screen—it’s the "hidden hero" inside: the rigid-flex PCB.

Unlike traditional smartphones (with rigid PCBs that never bend), foldable phones need a circuit that can fold 200,000+ times (the industry standard for durability) and keep power/signal flowing stable. It’s a tightrope walk: too flexible, and the PCB breaks; too rigid, and the phone won’t fold smoothly. So how do engineers balance these two opposite needs? Let’s break down the 4 key solutions, using real examples from Samsung, Motorola, and Xiaomi.

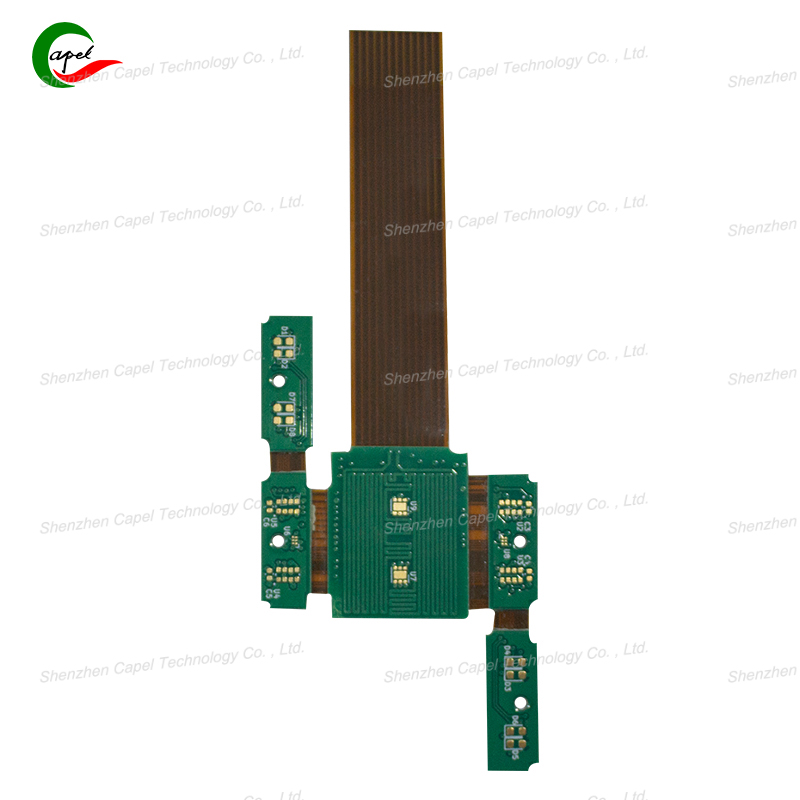

The core of a foldable phone’s rigid-flex PCB is its "layer mix": rigid sections hold heavy components (chips, batteries), while flexible layers handle the fold. Here’s how it works:

-

Rigid Layers (FR4 Material): These are placed in non-folding areas (e.g., the top/bottom of the phone). For example, Samsung’s Galaxy Z Fold5 uses 2 rigid FR4 layers to house its processor and camera sensors—these layers never bend, so components stay secure.

-

Flexible Layers (Polyimide Material): A thin, 0.1mm polyimide layer runs along the fold. It’s flexible enough to bend 180° but strong enough to resist tearing. Motorola’s Razr+ uses a single polyimide layer in the fold area—tested to survive 200,000 folds without cracking.

This "split design" means the PCB is stable where it needs to be, and flexible where it counts. No more choosing one over the other—you get both.

Even the best layer design fails if the copper traces (the tiny wires that carry power/signal) are placed wrong. In foldable PCBs, traces along the fold are under constant stress—if they’re too straight or too thin, they snap. Engineers fix this with:

-

Curved Trace Patterns: Instead of straight lines, traces in the fold area are shaped like "S" curves or waves. These curves absorb stress when the phone folds—like how a spring bends without breaking. Xiaomi’s Mix Fold 3 uses S-curve traces; testing showed they last 30% longer than straight traces.

-

Wider Trace Width: Fold-area traces are 0.2mm wide (vs. 0.1mm in rigid PCBs). Thicker traces are harder to break—Samsung’s tests found that 0.2mm traces survive 250,000 folds, while 0.1mm traces fail at 120,000.

Trace routing isn’t just about functionality—it’s about durability. A well-placed trace keeps the phone working for years.

When a phone folds 200,000 times, the glue holding rigid and flexible layers together can weaken—causing layers to separate and the PCB to fail. To prevent this:

-

Heat-Activated Adhesives: Instead of regular glue, manufacturers use adhesives that harden at 120°C and resist repeated bending. Samsung uses this in the Z Flip5—its bonding adhesive stays strong even after 300,000 folds.

-

Edge Sealing: The edges of the rigid-flex PCB are coated with a waterproof, flexible sealant. This stops dust/moisture from getting between layers (which weakens bonding) and adds extra strength. Motorola’s Razr+ uses a silicone sealant—testing showed it reduced layer separation by 80%.

Strong bonding ensures the PCB acts as a single unit, not separate rigid and flexible parts.

No design is perfect until it’s tested. Engineers put rigid-flex PCBs through "torture tests" to make sure flexibility and stability hold up:

-

Fold Cycle Testing: Machines fold the PCB 200,000 times (equivalent to 5 years of use) at different angles (90°, 180°) and temperatures (-10°C to 45°C). If the PCB survives, it moves to the next test.

-

Stress Testing: Weights are attached to the rigid sections while the PCB folds—mimicking the pressure of a user’s hand. Xiaomi’s Mix Fold 3 PCBs passed this test with 500g weights, proving they can handle daily use.

-

Signal/Power Testing: During folding, engineers check if power/signal drops. A 1% drop means the design is flawed—Samsung’s Z Fold5 PCBs had 0.2% signal loss, well below the 1% threshold.

Testing turns "good on paper" designs into "reliable in real life" products. It’s the final check to ensure balance between flexibility and stability.

Rigid-flex PCBs are the unsung heroes of foldable phones. They solve the impossible problem: making a circuit that bends like a ribbon and stays stable like a brick. By mixing rigid/flexible layers, routing traces carefully, using strong bonding, and testing rigorously, engineers have turned foldable phones from a novelty into a durable product.

Next time you fold your phone, remember: the smooth, reliable fold isn’t magic—it’s the result of thousands of hours of designing, testing, and balancing two opposite needs. And as rigid-flex PCB tech improves, foldable phones will only get more durable, more affordable, and more common. The future of foldables isn’t just about bigger screens—it’s about better balance.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.