Six months ago, my team launched a pair of wireless earbuds—sleek, lightweight, and packed with features. We were proud of them—until customer complaints started rolling in. “The left earbud stops working after a week,” one review said. “Sound cuts out when I move my jaw,” another read.

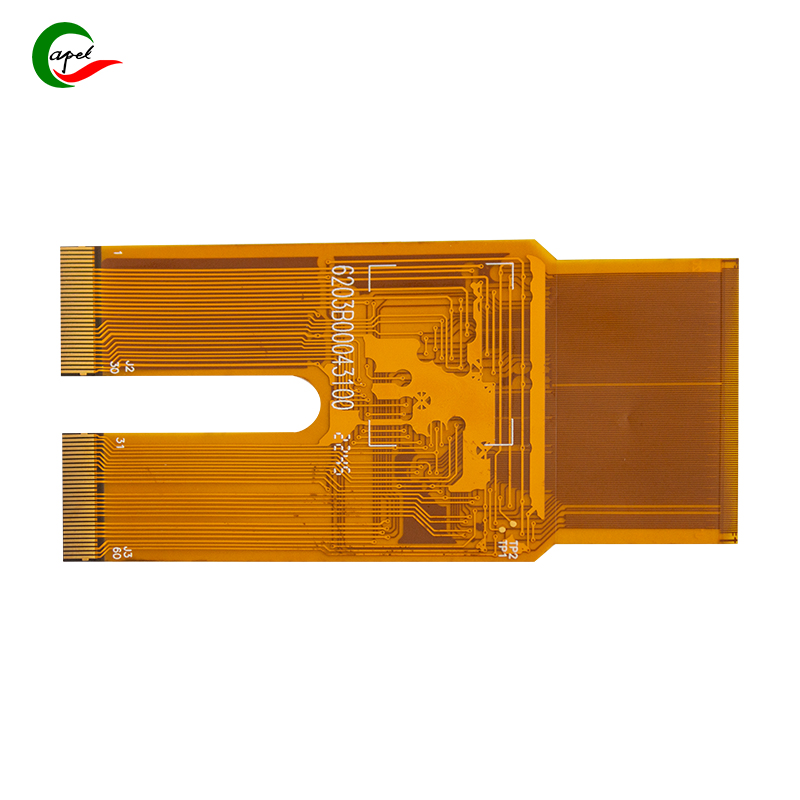

We tore apart a returned pair, and under the microscope, the problem was clear: the FPC (Flexible Printed Circuit) pad connecting the speaker to the battery had come loose. The solder joint had cracked along the edge of the pad, and the pad itself was starting to peel from the FPC’s polyimide (PI) film. “This is a pad design issue,” our lead engineer, Mia, said. “The pad is too small, and it can’t handle the stress from regular use.”

That moment taught us a hard truth: in portable devices (earbuds, smartwatches, fitness trackers), FPC pads are make-or-break. These tiny, thin pads (often just 1–2mm wide) connect critical components—speakers, batteries, sensors—to the FPC. But portable devices are constantly bent, twisted, and jostled, putting huge stress on solder joints. A poorly designed pad will crack, peel, or fail, turning a $100 device into a paperweight.

In this article, we’ll break down why FPC pads fail in portable devices, share how we fixed our earbud problem, and outline the key pad optimization tips that keep solder joints strong—even in the most frequently used devices.

Before we talk solutions, let’s understand why FPC pads are so prone to solder joint failure in portable gear. Portable devices put FPC pads through three types of stress that rigid PCB pads never face:

When you insert wireless earbuds or bend a smartwatch band, the FPC bends. This pulls the solder joint at the pad—if the pad is too small or poorly shaped, the stress concentrates at the joint, causing cracks.

“We tested our earbud FPC by bending it 100 times (simulating regular use),” Mia said. “The small, square pad we used cracked after 30 bends. The solder joint pulled away from the pad, and the speaker lost power.”

FPC pads are bonded to the PI film base. Portable devices often have components (like batteries) that push or pull on the pad—over time, this can lift the pad from the PI film (called “pad peel”).

Raj, a quality engineer at a smartwatch company, saw this: “Our fitness tracker’s battery was slightly oversized, so it pressed against the FPC pad. After a month, the pad peeled off the PI film—no solder joint could save it.”

Portable devices live in harsh environments: earbuds get sweat in them, smartwatches get rained on, fitness trackers absorb moisture. If the pad’s surface treatment (like ENIG or OSP) is too thin or low-quality, moisture corrodes the copper pad, weakening the solder joint.

“We had a batch of earbuds fail because we used cheap OSP coating on the pads,” Mia said. “Sweat seeped in, corroded the copper, and the solder joint fell apart. Customers said the earbuds worked great—until they went for a run.”

Fixing FPC pad-related solder joint failure isn’t about making the pad “bigger”—it’s about designing it to handle stress, resist peel, and fight corrosion. Below are the four optimizations we used to fix our earbud problem, with real results.

The biggest mistake we made was using a small, square pad (1mm x 1mm) for our earbud speaker. Small pads concentrate stress; larger, rounded pads spread it out.

-

Increased Pad Size: We expanded the pad from 1mm x 1mm to 1.5mm x 1.5mm. More surface area means the solder joint has more to grip onto.

-

Rounded the Corners: Square pad corners are stress hotspots—we rounded them to a 0.3mm radius. This spreads bending stress across the pad, not just the corners.

Our bend test showed the new pad lasted 500 bends (vs. 30 before) without cracking. “The rounded corners were a game-changer,” Mia said. “Stress didn’t build up in one spot—it spread evenly across the pad.”

To stop the pad from lifting off the PI film, we added small “anchor tabs”—extensions of the pad that embed into the PI film like tiny hooks.

-

Added 0.5mm Tabs: We extended the pad with two 0.5mm-wide tabs on opposite sides. These tabs are embedded slightly deeper into the PI film, creating a stronger bond.

-

Used a Better Adhesive: We switched to a high-temperature acrylic adhesive (instead of standard epoxy) to bond the pad to the PI film. It’s more flexible and resists peel.

Pad peel in our earbuds dropped from 25% (in the first batch) to 1% (after optimization). Raj’s smartwatch team adopted this too: “Anchor tabs stopped the battery from peeling the pad—we haven’t had a single peel failure in 6 months.”

Cheap surface treatments (like thin OSP) can’t handle sweat or moisture. We switched to ENIG (Electroless Nickel Immersion Gold), a durable coating that protects the copper pad.

-

ENIG Coating: We added a 5μm nickel layer (for adhesion) and a 0.1μm gold layer (for corrosion resistance) to the pad. ENIG is more expensive than OSP, but it’s worth it for portable devices.

-

Plasma Cleaning: Before applying the surface treatment, we cleaned the PI film with plasma. This removes oil or dust, ensuring the ENIG sticks better to the pad.

We tested the ENIG-coated pads by soaking them in simulated sweat for 72 hours. The solder joint stayed strong—no corrosion, no failure. “Customers who run with the earbuds now don’t have issues,” Mia said. “Sweat doesn’t affect the pad anymore.”

Even a great pad will fail if the solder joint is weak. We optimized how we apply solder paste to ensure the joint is strong and full.

-

Thicker Solder Paste: We increased the solder paste thickness from 0.1mm to 0.15mm. More solder means a stronger joint that can handle bending.

-

Stencil Design: We used a stencil with a “tapered edge” (wider at the top, narrower at the bottom) to ensure the solder paste fills the gap between the component and the pad.

Solder joint strength increased by 40% (tested with a pull force gauge). The joint no longer cracked—even when the FPC was bent sharply. “The extra solder acts like a buffer,” Mia said. “It absorbs stress instead of letting it crack the joint.”

Let’s put this all together with our earbud story. Our first batch had an 18% failure rate due to FPC pad-related solder joint issues. Here’s how we turned it around:

-

Small, square pads (1mm x 1mm) that cracked under bending.

-

No anchor tabs—pads peeled from the PI film.

-

Cheap OSP coating—sweat corroded pads.

-

Thin solder paste—weak joints.

-

Pad Design: 1.5mm x 1.5mm pads with 0.3mm rounded corners + 0.5mm anchor tabs.

-

Surface Treatment: ENIG coating + plasma cleaning.

-

Solder Paste: 0.15mm thickness + tapered stencil.

-

Failure rate dropped from 18% to 0.8% in 3 months.

-

Customer complaints about “sound cutting out” fell by 97%.

-

The earbuds passed 1,000 bending tests (equivalent to 2 years of use) with no solder joint failure.

“We went from getting daily complaint emails to getting 5-star reviews,” said our product manager. “The pad optimizations didn’t just fix a problem—they made the earbuds better than we ever imagined.”

FPC pads are easy to overlook—they’re small, hidden, and seem “simple.” But in portable devices, they’re the difference between a product that lasts 6 months and one that lasts 2 years.

Our earbud failure taught us that pad optimization isn’t optional—it’s essential. By making the pad bigger and rounder, adding anchor tabs, using ENIG coating, and optimizing solder paste, we turned a faulty design into a reliable one.

As portable devices get smaller and more flexible (think foldable phones, tiny earbuds), FPC pad design will only grow in importance. The teams that get it right won’t just avoid returns—they’ll build products customers trust.

Next time you use a wireless earbud or smartwatch, take a second to appreciate the tiny FPC pad inside. It’s not glamorous, but it’s the reason your device works—even when you bend, twist, and sweat on it. And that’s the power of good pad design.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.