Date: 2025-11-01

You know that sinking feeling when your multilayer boards come back with alignment issues? Those tiny misalignments that mess up your circuit connections and kill your yield? We've been there too, and here's how we're fixing it for good.

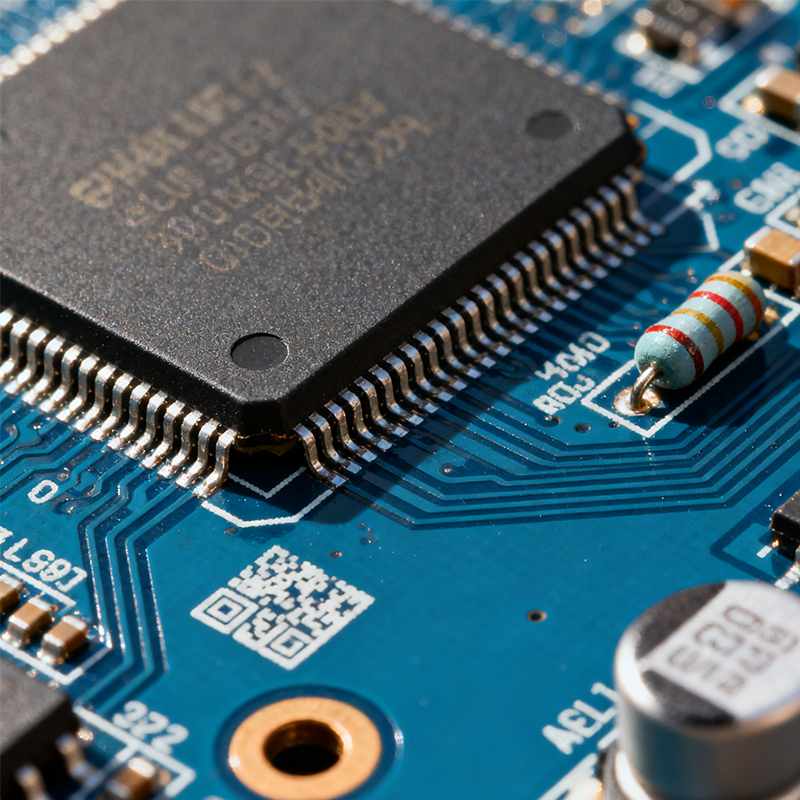

We use a smart combo of camera-guided alignment and precision placement that's like giving your boards GPS-level accuracy. Our CCD optical system acts as super-powered eyes that spot alignment markers and automatically adjust for any board warping or positioning errors. Then our placement machines put components down with surgical precision.

Here's what working with us looks like:

We'll explain it straight: "Our cameras scan your board's alignment marks and make micro-adjustments to keep everything within 0.01mm tolerance." No engineering degree required to understand what we're doing.

We customize the process for your specific boards. Dealing with 8-layer designs? Ultra-fine pitch components? We've handled the tough cases and know how to adapt.

You'll see actual alignment reports and placement accuracy data. We show you the numbers and photos so you know exactly what you're getting.

Why this approach actually matters:

Your multilayer boards stop failing from alignment issues

Your production yield jumps up because we're hitting that 98%+ pass rate

You save money by eliminating scrap and rework

The results speak for themselves - we're seeing 95% fewer alignment-related defects. The camera system catches positioning errors before they become problems, while the precision placement makes sure everything goes down exactly where it should.

We use this for everything from complex consumer electronics to industrial control systems where reliability is non-negotiable. The method works because it's both smart and precise.

If you're tired of alignment problems wrecking your multilayer PCBA production, this camera-guided approach could be your solution. We're helping manufacturers build better boards by nailing the alignment every single time. Your yields improve, your costs drop, and you can finally stop worrying about those frustrating misalignment issues.

We've helped companies solve this exact problem across multiple industries. The technology exists - you just need someone who knows how to implement it properly for your specific needs.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..