Date: 2025-10-30

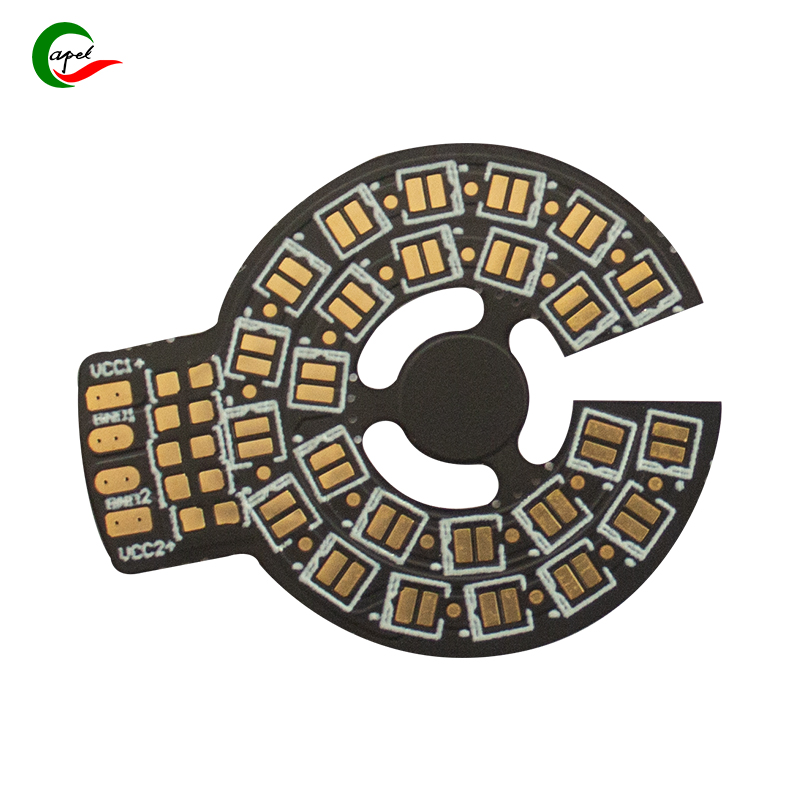

Let's be real - we've all struggled with trying to route a million connections in a space the size of a postage stamp. You're designing wearables, medical sensors, or IoT gadgets, and there's just never enough room for all the traces you need. The board ends up either too big or too limited in what it can do.

Here's how buried and blind vias solve this mess:

Think of regular vias like tunnels that go through the entire board - they take up space on every layer. Buried vias are like secret passages that only connect inner layers, while blind vias connect surface layers to inner ones without going all the way through. This means we can stack connections vertically without wasting precious surface real estate.

Working with us on this is pretty straightforward:

We'll look at your design and show you exactly where these special vias can free up space. No confusing technical lectures - just practical suggestions like "Hey, if we put a buried via here, you can run three more traces through this crowded area."

We customize the via layout based on your specific device. Working on a curved wearable? Need ultra-thin medical equipment? We'll adapt the approach to fit your exact needs.

You'll see actual progress photos and test results showing how we're packing more functionality into your limited space. We believe in showing you the proof, not just making promises.

Why should you care about this?

You can actually fit all the features you want without making the device bigger

Your devices can stay slim and compact while doing more

Signals stay cleaner because we're shortening connection paths and reducing interference

What makes our via process work:

We use laser drilling that's precise enough to create vias as small as 0.1mm without damaging the flexible board materials

Your boards stay flexible and bendable - we're not turning them into rigid bricks

We've used this approach successfully in everything from smartwatches to medical patches to industrial sensors

The bottom line? If you're tired of making compromises between device size and functionality, buried and blind vias could be your solution. We're helping manufacturers create smaller, smarter products by making every millimeter of circuit board space work harder. Your devices can do more in less space, and you can stop worrying about routing nightmares.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..