Date: 2025-08-03

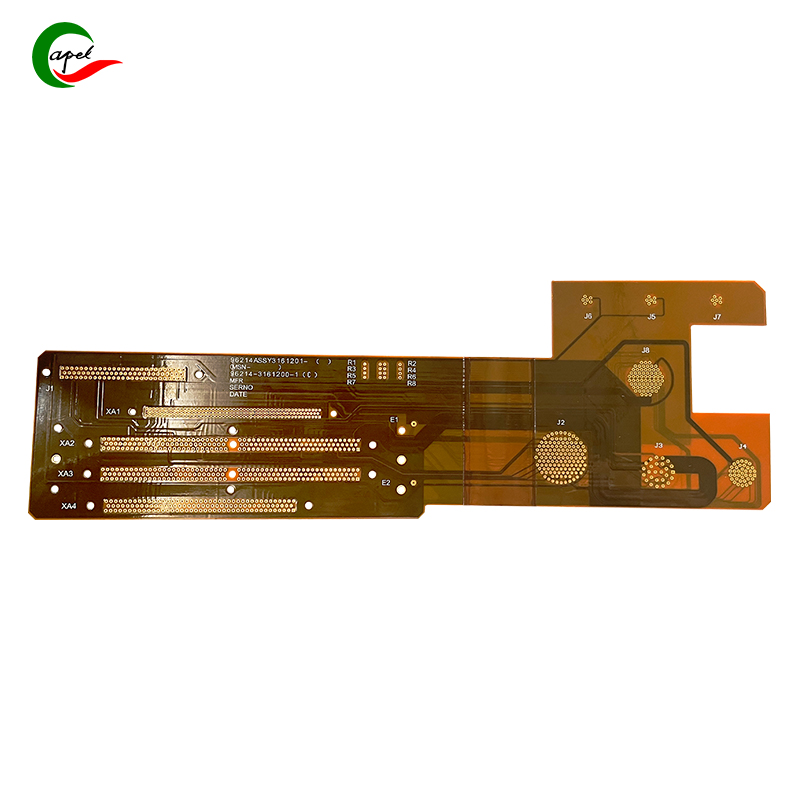

Ever folded your smartphone 100 times a day without a second thought? Or twisted your smartwatch band during workouts, trusting it won't snap? This reliability comes from flexible printed circuits (FPCs) - the unsung heroes of modern electronics.

But how do these ultra-thin circuits withstand daily stresses that would destroy traditional circuit boards? Let's uncover their secrets.

Polyimide (PI) Substrate: Thinner than paper (just 25 microns) yet incredibly strong, withstanding temperatures from -269°C to 400°C. Its molecular memory allows perfect recovery after bending. The hinge in Samsung Galaxy Z Fold uses PI to survive 100,000+ folds.

Rolled Copper Traces: Specially processed for 15-20% stretchability, with self-healing microstructure to prevent fatigue. Lab tests show zero failures after 200,000 bends.

Advanced Protective Layers: Laser-cut coverlays provide protection while maintaining flexibility. Waterproof yet breathable designs resist sweat and rain, with self-healing capabilities coming in next-gen versions.

Ultra-thin 0.1-0.3mm design significantly reduces bending stress

Gentle curved traces replace sharp 90° turns

Strategic reinforcement at critical points balances strength and flexibility

Foldable phones: Enable 100,000+ hinge folds

Smartwatches: Support 500+ daily bends

Automotive electronics: Withstand extreme temperatures (-40°C to 105°C)

Medical devices: Precisely conform to body contours

Stretchable circuits (300%+ elasticity)

Self-healing flexible circuits

Transparent flexible electronic components

Though small, flexible circuits are crucial for modern electronics reliability. They enable $1,000+ devices to endure daily use, while costing less than a cup of coffee to manufacture.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..