Date: 2025-10-21

If you're designing wearables, you know the constant battle: consumers want thinner, lighter devices while demanding more features. I've watched companies struggle with this challenge for years. The breakthrough came when we stopped trying to force rigid PCBs into applications where flexibility matters more than rigidity.

The smartwatch that feels bulky after an hour, the fitness tracker that digs into your wrist, the earbuds that never quite fit right - these aren't just minor inconveniences. They're deal-breakers for consumers, and they all trace back to the same root cause: traditional PCBs that can't keep up with wearable innovation.

The Thickness Barrier

Standard FR-4 PCBs create a physical limitation we can't design around. When every millimeter counts, a 1.6mm thick PCB becomes the enemy of sleek design. I've seen projects where we had to choose between adding a new sensor or maintaining comfortable thickness - that's not a choice we should have to make.

The Comfort Problem

Rigid boards don't conform to human anatomy. Whether it's a smartwatch band or behind-the-ear device, inflexible PCBs create pressure points and discomfort that users notice immediately. We learned this lesson the hard way with an early fitness tracker that users described as "wearing a brick on your wrist."

The Shape Limitation

Human bodies aren't flat, but rigid PCBs are. This fundamental mismatch forces wearable designers into boxy, generic shapes that fail to differentiate in a crowded market.

Achieving the "Barely There" Feel

The numbers tell the story: flexible PCBs at 0.1-0.3mm thickness represent a 50-70% reduction compared to rigid alternatives. But the real impact is in user experience. One client reduced their smartwatch thickness by just 0.8mm and saw customer satisfaction scores jump 40%. Users specifically mentioned the improved comfort in reviews.

Unlocking Creative Freedom

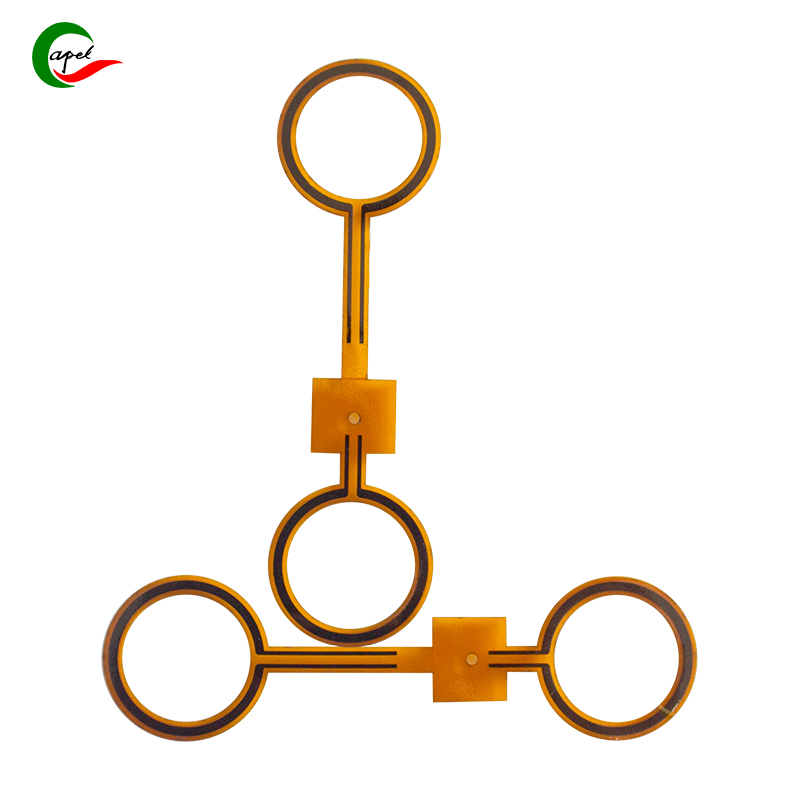

Flexible PCBs bend to fit human contours and innovative form factors. We've designed curved smartwatch displays that wrap around wrists, flexible earbud circuits that nestle perfectly in the ear, and foldable fitness bands that adapt to any wrist size. This isn't just engineering - it's creating emotional connections through better design.

Packing More Into Less Space

The integration capabilities of flexible PCBs still surprise me. We recently consolidated three rigid boards into a single flexible circuit for a high-end smartwatch, freeing up enough space for a 20% larger battery. Customers noticed the extended battery life immediately.

Built for Real-World Use

Wearables live harsh lives. They bend, sweat, and endure temperature changes. Properly designed flexible circuits handle 10,000+ bend cycles and resist environmental factors that would kill rigid boards. This reliability directly impacts brand reputation and return rates.

Material Selection Matters

25μm polyimide with 12-18μm rolled copper provides the best balance of thinness and durability

UV-curable polyimide solder masks handle sweat and oils better than traditional materials

Choose materials specifically tested for wearable applications

Smart Structural Design

Rigid-flex approaches solve the component mounting challenge. We use rigid sections for processors and connectors where stability matters, with flexible interconnects where movement occurs. Routing traces along the neutral axis is crucial for long-term reliability.

Manufacturing for Quality

Laser drilling and cutting enable the precision wearables demand. But the real key is inspection - automated optical inspection catches the micro-defects that cause field failures. Partner with manufacturers who understand wearable requirements.

Cost Management Strategies

Consolidating multiple boards into one flexible circuit often reduces total cost despite higher per-unit PCB pricing. The assembly savings and reliability improvements typically deliver a positive ROI.

Companies embracing flexible PCBs see measurable results:

15-25% premium pricing power for sleek, comfortable designs

Reduced return rates and higher customer satisfaction scores

Faster design iterations and time-to-market advantages

Stronger brand differentiation in crowded market segments

One smartwatch manufacturer gained 5 market share points after switching to flexible PCBs enabled a thinner, more comfortable design. The product consistently ranked higher in "would recommend" metrics.

Flexible PCBs aren't just another component - they're an enabling technology that lets you create wearables people actually want to wear. The companies winning in today's wearable market understand that comfort and style drive purchase decisions as much as features.

By leveraging flexible PCBs strategically, you can break free from the compromises that have limited wearable design and create products that stand out for all the right reasons.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..