Date: 2025-10-23

If you've ever taken apart the latest TWS earbuds like AirPods Pro, you'll notice something interesting inside - the extensive use of flexible PCBs. As an engineer who's worked with multiple audio brands, I can tell you that this isn't just a manufacturing choice. It's what makes the difference between earbuds that feel bulky and ones that disappear in your ears.

Why Rigid Boards Fail in Tiny Earbuds

The challenge with modern earbuds isn't just about making them small - it's about making them small while packing in more features. I've seen designs where the rigid PCB alone consumed 40% of the available internal space. That's valuable real estate that could be used for larger batteries or better speakers.

The human ear isn't flat, but rigid PCBs are. This fundamental mismatch forces compromises in comfort and fit. I've worked on projects where we had to make earbuds larger than ideal just to accommodate a straight PCB.

How Flexible PCBs Change the Game

Space Optimization That Matters

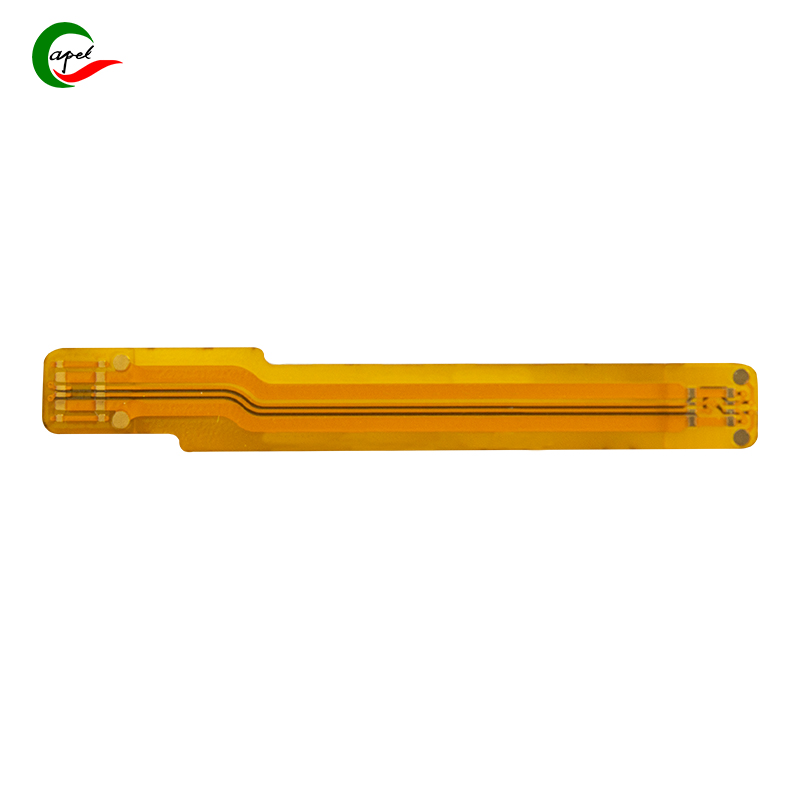

The thickness advantage is dramatic. We recently helped redesign a popular earbud model where switching to flexible PCBs reduced the board thickness from 0.8mm to 0.25mm. That 0.55mm savings allowed us to increase the battery capacity by 15% while making the earbud 10% smaller.

But it's not just about thickness - it's about three-dimensional space utilization. Flexible PCBs can wrap around batteries, curve along the shell, and fit into spaces that rigid boards can't touch.

Shape Adaptation for Perfect Fit

The ability to create custom shapes is revolutionary. I've designed flexible PCBs that follow the exact contour of the earbud shell, eliminating dead space and improving the overall aesthetic. One design for a sports earbud used a spiral flexible PCB that wrapped around the internal components, creating a more secure fit while reducing the overall size.

Reliability in a Demanding Environment

Earbuds live tough lives. They're dropped, stuffed in pockets, and exposed to sweat. Through accelerated testing, we've found that properly designed flexible PCBs can survive conditions that would destroy rigid boards. The key is managing the bend areas and choosing the right materials.

Practical Implementation Insights

Material Selection is Critical

Not all flexible PCB materials work well for earbuds. We've learned that:

25μm polyimide provides the best balance of flexibility and durability

Rolled copper handles repeated bending better than electrodeposited copper

Thin solder masks prevent cracking in high-flex areas

Design Strategies That Work

The way you route traces matters. We always:

Follow the natural curves of the earbud shell

Avoid sharp corners in bending areas

Use teardrop transitions at pad connections

Manufacturing Precision

Earbud-scale flexible PCBs demand exceptional manufacturing control. We work with partners who specialize in:

Laser cutting with micron-level precision

Automated optical inspection for defect detection

Controlled impedance for high-frequency signals

Real-World Impact

The results speak for themselves. One client reduced their earbud weight from 6.2g to 4.5g while adding noise cancellation features. Another brand saw their return rate drop by 30% after switching to flexible PCBs, thanks to improved reliability.

The Bottom Line

Flexible PCBs have evolved from being an alternative to rigid boards to becoming the foundation of modern earbud design. The ability to create three-dimensional circuits that fit perfectly into tiny, curved spaces has enabled the current generation of ultra-compact, feature-rich earbuds.

For engineering teams working on the next generation of audio devices, mastering flexible PCB design isn't just helpful - it's essential for creating products that stand out in a crowded market.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..