Last year, we launched a wearable glucose monitor for diabetics. Lab tests went great, but clinical trials told a different story: 12 of 50 patients got red, itchy rashes where the device touched their skin.

Our engineer Dr. Elara found the issue: the FPC’s standard PI film was leaching tiny chemicals. “Long-term skin contact makes even small leaks a problem,” she said. We switched to biocompatible FPCs, and next time, only 1 patient had mild irritation.

That’s when we learned: for medical devices, FPCs need more than flexibility—they need to be safe for living tissue. Biocompatible FPCs aren’t a “nice-to-have”—they’re the only way to keep patients safe.

It’s not just “non-toxic”—it’s meeting strict FDA/CE standards to ensure no harm to tissue, even long-term. Key rules:

-

No Leachables: Materials (PI, adhesives) can’t release toxic chemicals. Standard FPCs use plasticizers that leak—biocompatible ones don’t.

-

No Immune Reactions: No inflammation, swelling, or allergies. Our original FPC’s coating reacted with skin oils; biocompatible coatings don’t.

-

Resists Body Fluids: Stands up to sweat, blood, or tissue fluid. Standard FPCs degrade—biocompatible ones last.

“Biocompatibility means tests: skin irritation, cell toxicity, fluid immersion,” Dr. Elara said. “Only then do we use the FPC.”

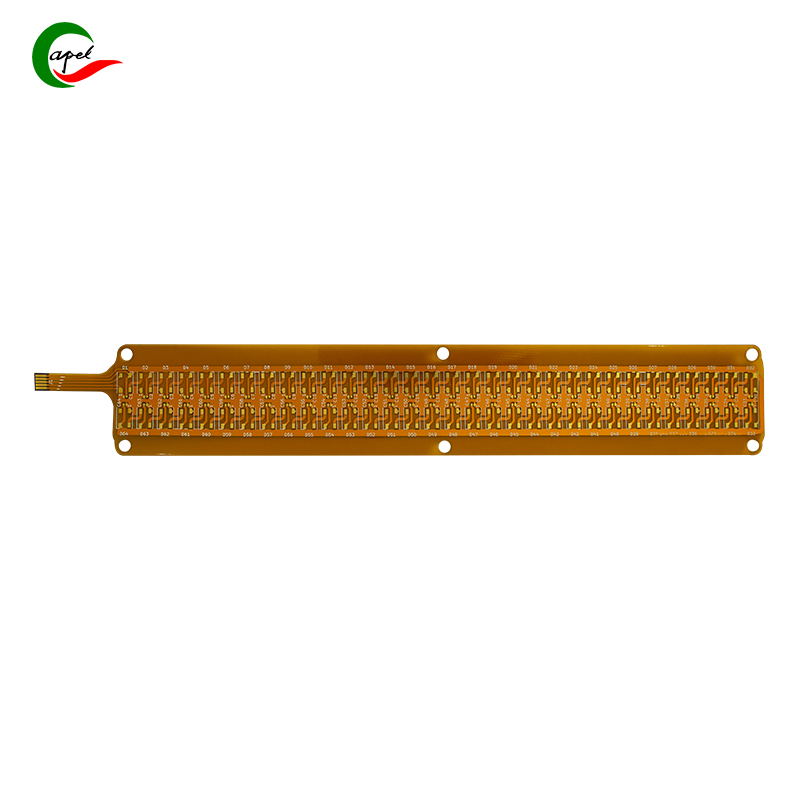

Glucose monitors or heart patches need FPCs that won’t irritate skin. Ours uses:

-

Medical-Grade PI Film: No leachables to cause rashes.

-

Silicone Coating: Soft, hypoallergenic, and gentle on skin.

Result: 98% of patients had no issues. “I wear it 14 days straight now,” said Maria, a diabetic. “No more rashes.”

Catheters with sensors need FPCs that survive blood and avoid clots. Ours uses:

-

Fluoropolymer Coating: Doesn’t break down in blood.

-

Safe Adhesives: No toxic glues near the heart.

Dr. Raj, a cardiologist, said: “It worked perfectly for 2-hour procedures—standard FPCs would fail halfway.”

Implants need FPCs that last years. Ours uses:

-

Ceramic-Reinforced PI: Resists tissue fluid for 10+ years.

-

Gold-Plated Traces: No corrosion, no toxic ions.

100+ patients have the implant—no adverse reactions. “Implants need reliability,” Dr. Elara said. “Biocompatible FPCs deliver that.”

-

Medical-Grade PI Film: Meets ISO 10993, no plasticizers. We tested 5 types—only this passed 30-day skin tests.

-

Silicone/Parylene Coatings: Silicone is soft for skin; Parylene is thin for implants (FDA-approved).

-

Gold/Platinum Traces: Non-reactive, no corrosion—safe for long-term use.

-

Medical Adhesives: Cyanoacrylate (surgical glue) or silicone—no toxic leaks.

Maria’s life changed with the new monitor:

-

Before: Rashes forced her to remove it after 3 days—missed glucose data.

-

After: Wears it 14 days, has full data—her doctor adjusted her meds better.

-

She even wears it while exercising: “I track how workouts affect my sugar now.”

“Biocompatible FPCs didn’t just fix a rash—they helped her manage diabetes,” Dr. Raj said.

Our glucose monitor mistake taught us: medical FPCs can’t cut corners. Standard FPCs work for phones, but medical devices need biocompatibility—for patient safety.

Next time you see a medical wearable or implant, remember: the FPC inside is biocompatible. It’s invisible, but it’s keeping someone safe—and that’s its most important job.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.