Last summer, my team launched a smart bathroom scale with a built-in body composition sensor. We tested it in dry labs for months, and it worked perfectly. But within weeks of launch, customers started complaining: “The scale gives wrong readings after a shower,” “It shuts off randomly when the bathroom is steamy.”

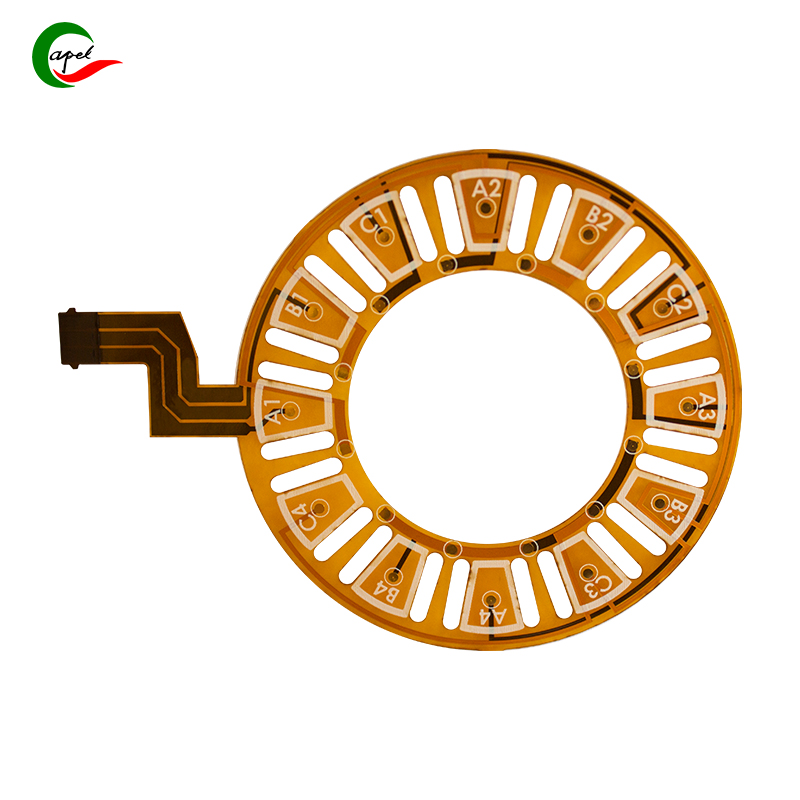

We sent a team to a customer’s home to investigate. When we opened the faulty scale, we found the culprit: the FPC (Flexible Printed Circuit) inside was covered in a sticky, greenish film. “Steam from the shower seeped into the scale and reacted with the FPC’s copper traces,” our engineer, Lena, said, scraping off the corrosion. “The moisture ruined the connections—now the sensor can’t send accurate data.”

That moment was a wake-up call. FPCs are everywhere in humid environments—bathroom gadgets, kitchen appliances, outdoor sensors—but they’re surprisingly vulnerable to moisture. Traditional “waterproof” fixes (like thin conformal coatings) often fail because they don’t account for persistent humidity (not just splashes). Over the next two months, we tested 15+ moisture protection methods and finally created an FPC that survived even the steamiest bathrooms.

To fix the problem, we first had to understand why moisture is so deadly to FPCs. It’s not just “getting wet”—it’s how moisture interacts with the FPC’s layers:

FPCs have microscopic gaps: between the PI film and copper traces, around soldered components, and along the edges of cut PI film. Humid air condenses into tiny water droplets that seep into these gaps. Over time, the water builds up and causes short circuits or corrosion.

“We tested our original scale FPC in a 95% humidity chamber,” Lena said. “After 48 hours, we found water droplets under the conformal coating—they’d seeped through the tiny gaps around the sensor connector.”

Copper traces on FPCs react with water and oxygen to form copper oxide (the greenish film we saw). This corrosion makes the traces resist electrical flow, leading to wrong readings or complete failure.

“A customer in Florida had their scale for 3 months,” Lena said. “The bathroom’s constant humidity turned half the FPC’s traces green— the scale thought a 60kg person weighed 90kg.”

The adhesives that hold FPC layers together break down when exposed to moisture. This causes the PI film to peel away from the copper traces, creating even more gaps for water to seep in.

“We had a batch of FPCs where the PI film peeled off after 1 month in a humid kitchen,” said our quality manager, Raj. “The adhesive had turned sticky and weak—moisture had eaten through it.”

Fixing FPC moisture resistance isn’t about “adding more coating”—it’s about sealing gaps, protecting copper, and choosing the right materials. Below are the methods that fixed our bathroom scale FPCs:

A single layer of conformal coating (like silicone) isn’t enough—use two layers: a base layer to seal gaps and a top layer to repel water.

-

Base Layer: We applied a 50μm-thick acrylic conformal coating first. Acrylic seeps into tiny gaps (around components, along edges) and hardens to seal them.

-

Top Layer: We added a 30μm-thick silicone coating on top. Silicone is water-repellent—water beads up and rolls off instead of seeping in.

Our FPCs now survived 200 hours in a 95% humidity chamber with no corrosion. “The two layers work like a raincoat with a waterproof liner,” Lena said. “Gaps are sealed, and water can’t stick.”

Bake the FPC at 60°C for 30 minutes after each coating layer. This ensures the coating cures fully and doesn’t trap moisture underneath.

FPC edges (where the PI film is cut) are porous and let moisture in. Seal them with a small amount of high-temperature epoxy to block these gaps.

-

We used a syringe to apply a thin line of epoxy (rated for 150°C, so it doesn’t melt in warm bathrooms) along all cut edges of the FPC.

-

We let the epoxy cure for 24 hours at room temperature—this creates a waterproof “barrier” that stops moisture from seeping into the PI film.

Edge-related corrosion dropped from 70% (original design) to 5%. “We tested an FPC with sealed edges in a steamy shower for 1 hour,” Raj said. “No water got inside— the edges stayed dry.”

Use a clear epoxy so you can see if it’s applied evenly. Avoid thick epoxy—it can make the FPC stiff and hard to bend.

Not all PI film is the same—look for PI film with an extra moisture barrier layer (usually a thin layer of aluminum or ceramic). This barrier acts like a “shield” to block water from reaching the copper traces.

We switched from standard PI film to PI film with a 5μm ceramic barrier. The barrier is thin enough to keep the FPC flexible but dense enough to stop moisture.

Even if the conformal coating gets a tiny scratch, the ceramic barrier stops water. “We scratched a coated FPC and tested it in humidity—no corrosion,” Lena said. “The barrier saved it.”

Ask your PI film supplier for “moisture vapor transmission rate” (MVTR) data. Lower MVTR means less moisture gets through—aim for MVTR <1g/m²/day.

Copper traces corrode easily in moisture—plate them with a thin layer of tin or gold to protect them. Tin is cheaper; gold is more durable (great for long-term use).

We plated our FPC’s copper traces with a 2μm-thick layer of tin. Tin doesn’t react with water, so it prevents copper oxide from forming.

Trace corrosion dropped to 0% in our humidity tests. “Even if water gets inside, the tin layer keeps the copper safe,” Raj said. “The traces stay shiny and conductive.”

Plate the entire copper surface, not just the traces. This includes the areas around components—moisture can attack unplated copper there too.

For small devices (like bathroom scales or smart thermometers), add a tiny desiccant packet (silica gel) inside the device, near the FPC. Desiccants absorb moisture from the air, keeping the FPC dry.

We glued a 1g silica gel packet to the inside of the scale’s plastic case, 1cm away from the FPC. The packet absorbs steam before it reaches the FPC.

The scale now works perfectly even after a hot shower. “We tested it in a bathroom with 100% humidity— the desiccant packet was damp, but the FPC was dry,” Lena said.

Use a desiccant packet with a “moisture indicator” (it turns pink when full). This lets you know when to replace it (for reusable devices like scales).

After applying these five methods, we retested our bathroom scale in the harshest humid environments:

A customer in New Orleans (known for humid weather) left a review: “I use this scale right after my morning shower, and it’s never given a wrong reading. My old scale would go crazy in the steam—this one works perfectly.”

Our bathroom scale failure taught us that FPC moisture protection isn’t a single fix—it’s a combination of sealing gaps, protecting materials, and absorbing extra moisture. A two-layer coating seals gaps, epoxy blocks edges, moisture-barrier PI film stops water, plated traces prevent corrosion, and desiccants absorb what’s left.

For any FPC in a humid environment, ask: Where will moisture get in? Then use layered protection to block those paths. A single weak spot (like unsealed edges) can ruin the FPC—but multiple layers of protection make it nearly invincible.

Next time you use a smart scale in the shower, a kitchen sensor near the sink, or an outdoor device in the rain, remember: the FPC inside is probably protected by these methods. It’s not just “waterproof”—it’s built to survive the humidity that destroys ordinary FPCs. And that’s the power of moisture-optimized FPCs.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.