PCB Layout: Essential Principles for Reliable Electronic Designs

Date: 2025-09-10

PCB layout is the bridge between a theoretical schematic and a functional electronic device—but it’s where many designs hit roadblocks. It’s not just about drawing traces; it’s about following rules that prevent noise, overheating, and signal failure. Let’s break down the critical elements that every designer needs to master, with clear, real-world context.

Even small oversights in layout can disable an entire board. Here’s what to avoid:

- Thermal issues: Components that generate heat (like voltage regulators, LEDs, or power ICs) need space to dissipate. If they’re packed too tightly, heat builds up—leading to component failure or reduced lifespan. For example, a LED array laid out without gaps between diodes might dim prematurely, as excess heat degrades their performance.

- Signal noise: High-speed signals (such as USB 3.0, Ethernet, or RF) are sensitive to interference from power traces. Running these signal traces parallel to power lines, or placing them too close to noisy components (like motors or relays), can corrupt data—causing glitches in communication or sensor readings.

Trace width mistakes: Using a trace that’s too thin for high-current paths (e.g., power inputs for motors) leads to voltage drops and overheating. A 0.2mm trace, for instance, can only handle around 0.5A of current; using it for a 2A motor will result in the trace overheating and possibly burning out.

These principles apply to nearly every PCB design, from simple sensors to complex microcontroller boards:

- Group components by function: Keep power components (regulators, capacitors, batteries) in one area, and signal components (sensors, microchips, communication modules) in another. This separates noisy power paths from sensitive signals, reducing interference. For a temperature sensor board, for example, placing the 5V regulator far from the sensor IC ensures the sensor’s readings stay accurate.

- Optimize trace length and routing: High-speed signals need short, direct traces. For differential pairs (like HDMI or CAN bus), both traces must be the same length—even a 1mm difference can cause signal skew, breaking communication. For low-speed signals (like a simple button input), trace length is less critical, but keeping it short still reduces noise.

- Use Design Rule Check (DRC) early: DRC tools flag issues like trace-to-trace spacing violations, too-thin traces, or missing ground connections. Run DRC after finishing each section (e.g., power path, signal path) instead of waiting until the end. This catches small mistakes early—fixing a spacing error takes minutes, but reworking an entire board because of it wastes hours.

Rushing through layout to “finish fast” is the biggest mistake. Skipping DRC, ignoring trace width guidelines, or crowding components to save board space might seem efficient, but it leads to costly rework. For example, a designer who skips DRC might miss a trace that’s too close to a ground plane—resulting in a board that shorts out when powered on. Ordering new PCBs and reworking the design adds weeks to the timeline and wastes money.

PCB layout is about precision and foresight. By focusing on thermal management, signal integrity, and rule-checking, you can create boards that work reliably the first time. Whether you’re designing a hobby project or a commercial product, taking the time to follow these principles will save you frustration, time, and cost in the long run.

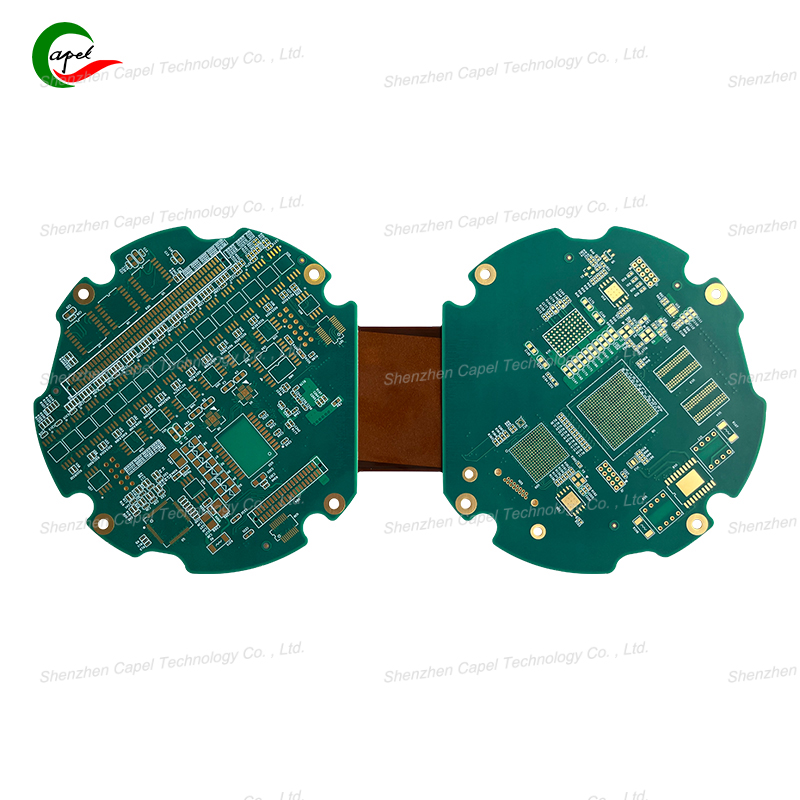

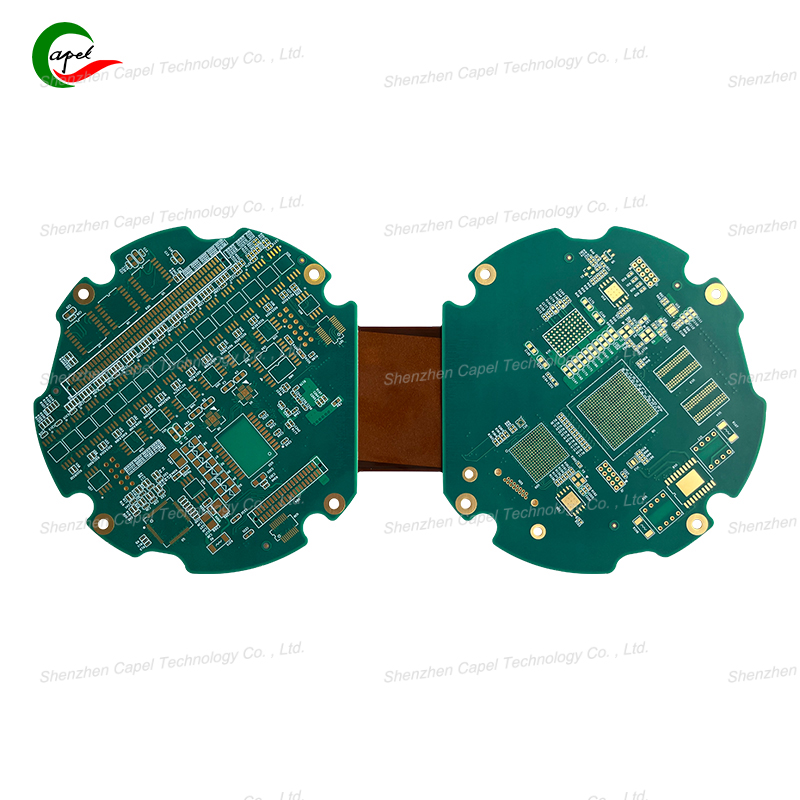

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.