Date: 2025-12-12

If you've ever marveled at how thin the latest smartphone is, or wondered how so much functionality fits inside a smartwatch, you've already been admiring the art of SMT assembly. SMT, or Surface Mount Technology, is the core manufacturing process that turns almost every modern electronic device from a blueprint into reality. Without SMT, the consumer electronics, IoT, and the entire digital world as we know it would simply not exist.

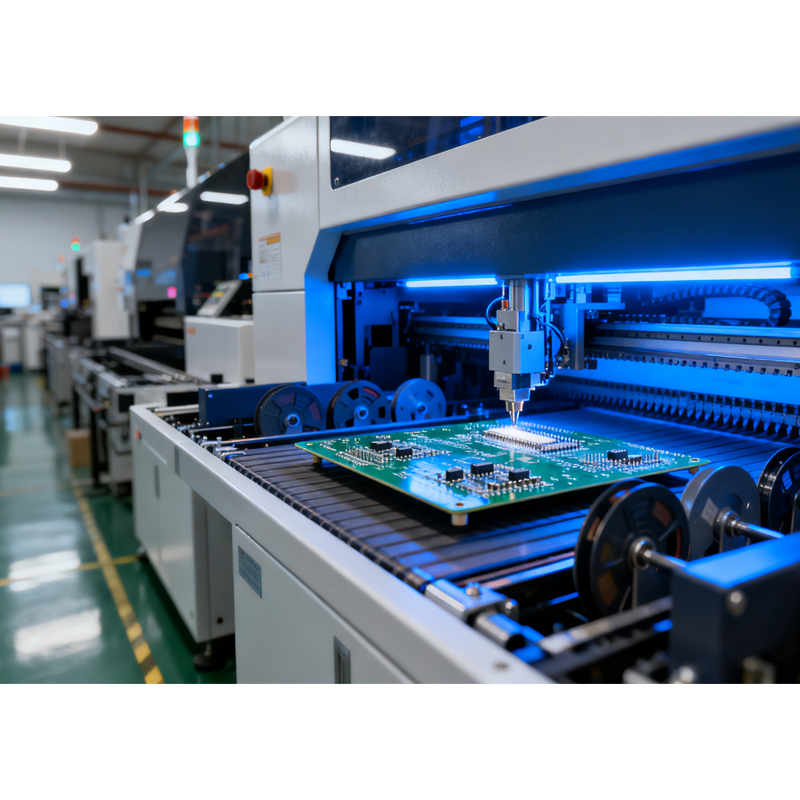

I'm from the Kaboer team, and on our production floors, millions of tiny components are precisely placed onto circuit boards every day via SMT. Today, I want to dive deep with you into this seemingly "standard" but profoundly complex technology—it's far more than just sticking parts onto a board.

Simply put, SMT is a method for mounting miniature, lead-less or short-lead electronic components (we call them Surface Mount Devices, or SMDs) directly onto the surface of a printed circuit board.

Imagine this: you need to place hundreds, even thousands, of components smaller than a grain of salt (some as tiny as 0.4mm x 0.2mm) onto a PCB no larger than a business card. You must do this at speeds of tens of thousands of placements per hour, with positional accuracy within a few dozen microns (a human hair is about 70 microns thick). And that's not even the hardest part—you must also ensure every single microscopic solder joint is perfect and reliable for the long haul. This is the miracle SMT performs daily.

Compared to its predecessor, Through-Hole Technology, which required inserting leads into holes, SMT was a revolution:

Smaller & Lighter: Components shrank dramatically, enabling device miniaturization.

Higher Density: Parts can be placed on both sides, exponentially increasing circuit density.

Faster & Automated: The fully automated, high-speed process enables modern mass production.

Better Performance: Shorter leads allow for superior high-frequency and high-speed signal performance.

A typical SMT line is a symphony of precision machines. Its core workflow consists of these critical stages:

1. Solder Paste Printing: "Drawing" the Precise Blueprint for Solder

This is the first and a critical gatekeeper of the entire process. A laser-cut stainless steel stencil is precisely aligned over the PCB. Solder paste—a viscous blend of microscopic solder spheres and flux—is rolled across the stencil by a squeegee, forcing it through the openings and depositing it onto the PCB pads. The consistency in volume and shape of this deposit is paramount. At Kaboer, we use fully automated optical printers with real-time SPC monitoring to ensure every board starts perfectly.

2. Component Placement: The High-Speed "Pick-and-Place" Ballet

The pick-and-place machine is the star of the line. It picks up tiny SMDs from reels, trays, or tubes, uses a high-resolution vision system for on-the-fly alignment correction, and then places them at lightning speed onto the pasted pads. Modern high-end placers can handle everything from 01005 micro-components to large BGAs and CSPs with accuracies down to ±25 microns. Our lines are equipped with a mix of platforms to balance ultra-high-speed placement with the precision needed for complex, irregular components.

3. Reflow Soldering: The Thermal Dance That Creates "Permanent" Bonds

The populated PCB travels through a reflow oven. This isn't a simple oven but a tunnel with a precisely programmed thermal profile. The board goes through preheat, soak, reflow, and cooling zones. In the reflow zone, the temperature peaks above the solder's melting point. The solder spheres melt, and driven by surface tension and flux action, form perfect intermetallic compounds with the component terminations and PCB pads before solidifying into a strong, reliable joint. Profiling and monitoring this temperature curve is the soul of the process, ensuring good yield and preventing defects like cold solder or thermal damage.

4. Inspection & Verification: The Uncompromising Quality Guardians

Post-solder is not the end. In modern high-reliability manufacturing, Automated Optical Inspection uses high-definition cameras to 3D-scan every board, checking for component presence, correct placement, polarity, and solder joint shape. For components with hidden joints underneath, X-ray Inspection penetrates the package to inspect solder balls under BGAs, QFNs, etc., for bridging, voids, or other defects. At Kaboer, we treat AOI and X-Ray as mandatory in-process checkpoints, not final sampling tools, aiming to catch defects in real-time rather than sorting them out later.

Virtually every modern electronic product you see relies on SMT at its core. The breadth of its application dictates a wide spectrum of process requirements:

The Crown Jewels of Consumer Electronics: Smartphones, tablets, TWS earbuds. This is where SMT technology is pushed to its limits, demanding extreme component miniaturization, ultra-high density, and flawless reliability. Boards are complex HDI, components go down to 01005, with heavy use of CSP and PoP packaging.

The Backbone of Automotive Intelligence: From ADAS sensors and digital clusters to body control modules. Automotive electronics require SMT processes with exceptional robustness to withstand extreme temperatures and constant vibration. This demands stricter process controls, material selection, and 100% traceability.

The Engine of High-Performance Computing: Server motherboards, GPUs, network switch boards. These are often large, high-layer-count, high-value boards with critical thermal and signal integrity needs. The SMT process must perfectly handle large BGAs, high-current inductors, and minimize thermal stress.

The Body of Industrial & IoT: PLCs, IoT gateways, sensor modules. They need processes that remain stable under broader conditions and adapt to high-mix, low-to-medium volume production, valuing flexibility and consistency.

The Life-Critical Medical Core: As mentioned before, SMT for medical devices is performed in controlled environments under the highest standards. Every single process parameter must be documented, validated, and monitored, leaving zero room for error.

When your design moves from EDA software to physical boards, choosing who performs the SMT assembly determines half your product's fate. Looking only at the "cents-per-point" on a quote is the biggest trap. Here are more critical criteria:

1. Process Capability & Equipment Precision

What is the smallest component size they can place consistently? (We reliably handle 0201 and below.)

What is the placement machine's repeatability and CPK? (This speaks to long-term consistency.)

What is the reflow oven's zone count, temperature control accuracy, and nitrogen capability? (Critical for high-quality BGA soldering and oxidation prevention.)

2. Engineering Support & Design for Manufacturability

A superior SMT partner provides a professional DFM report before production. They review your design files, highlighting details that could cause placement issues, soldering defects, or testing problems—like insufficient component clearance or poor thermal relief design. This proactive step eliminates most potential failures, saving significant time and cost.

3. Depth & Philosophy of Quality Control

Is their approach "inspect at the end" or "prevent during the process"? We champion the latter. We monitor key process parameters like paste height, oven profile, placement pressure in real-time to ensure every board is made within the optimal process window.

Is the First Article Inspection process rigorous? The first assembled board must undergo detailed measurement and approval by engineering before batch production begins.

Is material management stringent? From solder paste in refrigerators and MSD components in dry cabinets to full-track traceability, material state must be controlled.

4. Supply Chain & Component Services

Can the partner offer component sourcing, kitting, and consignment services? A strong supply chain ally helps you navigate shortages, manage inventory, and lets you focus on core R&D.

5. Flexibility & Scalability

Do you need to iterate quickly on 50-piece prototypes and then smoothly scale to a 50,000-piece production run? The partner's line configuration and management systems must support this elasticity.

6. Transparency & Communication

Can you easily access production status, test reports, and issue feedback? A transparent partnership builds trust and enables faster problem resolution.

At Kaboer, we don't see ourselves as a simple "board house." We see ourselves as co-founders of our clients' product excellence. Our commitment in this core business of SMT is reflected in:

1. Data-Driven Precision Processes

We invest in leading SMT equipment, but more so in process knowledge and data systems. We monitor, log, and analyze every critical process parameter in real-time, using data to continuously refine our processes. This ensures consistently high-quality output, independent of individual operator skill.

2. Full Lifecycle Engineering Collaboration

From early DFM optimization advice, through in-production process fine-tuning, to post-mass-production continuous improvement, our engineering team is deeply involved. We understand that a minor design tweak can lead to a major boost in yield and reliability.

3. A Production System Built for Reliability

Whether it's the extreme efficiency needed for consumer electronics or the absolute reliability demanded by automotive and medical fields, we have corresponding validated process flows and quality control plans. Our systems are built on frameworks like IATF 16949 and ISO 13485, providing the foundation to serve high-end markets.

4. A Trustworthy, Turnkey Experience

From PCB and component supply to precision SMT assembly, selective wave soldering, testing, and box-build, we offer a seamless turnkey service. This not only shortens your supply chain but reduces friction, accelerates projects, and provides single-point accountability for quality.

SMT is the bedrock of electronics manufacturing. Its quality is built into your product and cannot be fixed later. Choosing Kaboer means choosing a partner obsessed with precision, committed to reliability, and dedicated to empowering your products with expert craftsmanship.

If you're tackling a challenging new design or have concerns about the manufacturing quality of an existing product, we are ready to support you with our expertise and production capability. Let's work together to build products that are not just functional, but durable and excellent.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..