Date: 2026-01-16

When designing a new product, you probably don't give much thought to the insulating material at the very bottom of the circuit board. But have you ever faced: unstable performance in high-frequency environments? Boards bubbling or warping during high-temperature operation? Or inconsistent yields in production despite identical designs? Often, the root cause points to the same place—the PCB substrate.

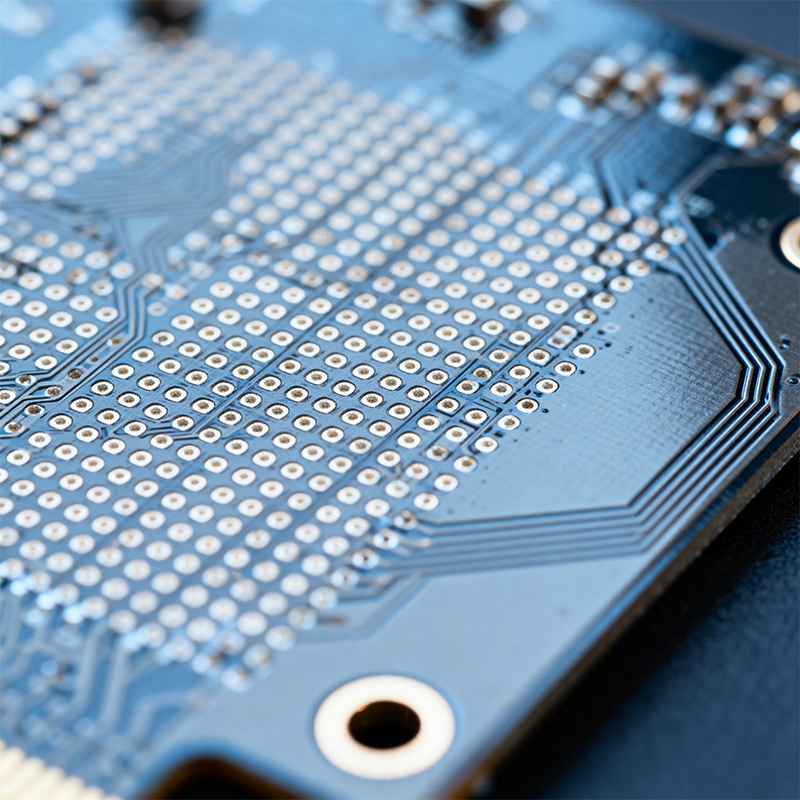

Simply put, the PCB substrate is the foundational insulating layer that carries all the copper traces and components. Think of it as a building's foundation—unseen above ground but determining the entire structure's stability and lifespan.

In a typical PCB, the substrate makes up over 90% of its thickness. It doesn't just provide mechanical support; it influences:

Electrical Performance: Signal transmission speed and quality

Thermal Management: How heat is conducted and dissipated

Mechanical Strength: Ability to withstand vibration, shock, and assembly stress

Long-Term Reliability: Functionality in harsh environments

Production Cost: Material cost and ease of processing

We believe you might be facing one of these situations:

Scenario 1: "I need to optimize my new product"

You may have a prototype but want to improve performance or reduce costs at the material level. You're wondering: "Are there better options than the FR-4 I'm using now? How much more would they cost?"

Scenario 2: "My design has hit a wall"

Perhaps your circuit underperforms at high frequencies or fails frequently in hot environments. You're asking: "Is the substrate limiting my design possibilities?"

Scenario 3: "I'm starting a new project"

You're planning a new product and want to choose the right material from the start. You need to know: "What are the rules for substrate selection in different applications?"

Whatever your situation, understanding the core properties and selection logic of substrates will help you make more informed decisions.

This is what you'll encounter most often, accounting for over 70% of global PCB usage. FR-4 isn't a single material but a broad category, much like "automobiles" includes various brands and models.

Its advantages are clear:

Best cost-effectiveness

Balanced mechanical and electrical properties

Most mature processing technology

Multiple supplier options, stable supply

But it has limitations:

Higher loss at high frequencies (Df ~0.02)

Moderate thermal performance (Tg typically 130-140°C)

Inferior long-term moisture and heat resistance compared to specialty materials

Best for: The vast majority of consumer electronics, industrial controls, automotive electronics (non-critical areas)

When signal frequencies exceed 1GHz, especially into 5G millimeter-wave bands, FR-4 no longer suffices. Two key parameters become critical:

Dielectric Constant (Dk): Lower is better—signals travel faster

Loss Tangent (Df): Lower is better—less signal energy loss

Common high-frequency materials include:

Rogers series: Excellent performance, but expensive

Taconic series: Relatively good cost-performance ratio

Isola's high-frequency grades: Emerging options, more flexible supply

Selection tip: Don't blindly pursue the lowest Dk/Df. Instead, balance cost and performance based on your actual frequency and performance requirements.

When your design has dense power components, thermal management becomes critical. Traditional FR-4 has a thermal conductivity of only 0.3-0.4 W/mK, while high-thermal-conductivity materials can reach 1.0-3.0 W/mK.

Applications:

High-power LED lighting (especially automotive headlights)

Power modules and converters

High-power motor drives

Implementation methods:

Use metal-core substrates (aluminum, copper)

Add high-thermal-conductivity fillers (like ceramic particles) to the resin

Use special thermally conductive adhesive layers

Some applications demand extreme reliability:

Automotive engine compartments: Temperatures above 150°C, plus vibration and chemical resistance

Downhole equipment: High temperature, pressure, and humidity

Aerospace: Extreme temperature cycling and vacuum environments

These materials typically feature:

Higher glass transition temperatures (Tg > 170°C)

Lower moisture absorption

Better CTE matching (thermal expansion coefficient closer to copper)

When your product needs to bend or space is extremely limited, flexible circuits become the only option. The primary material is polyimide (PI), known for excellent heat resistance, mechanical strength, and flexibility.

Typical applications:

Internal connections in smartphones and tablets

Sensor sections in wearable devices

Space-constrained wiring in automobiles

When facing a choice, follow this simple process:

Ask four key questions:

What is the operating frequency? (Determines if high-frequency materials are needed)

What is the operating temperature range? (Determines required Tg grade)

What are the expected environmental conditions? (Humidity, chemicals, vibration, etc.)

What is the target cost range? (Mass production or prototype?)

Filter from the strictest requirement:

If frequency > 1GHz → First consider high-frequency material options

If operating temperature > 130°C → Eliminate low-Tg materials

If bending is required → Only flexible substrates

After meeting basic requirements, consider:

Manufacturability: Is the material easy to process? Does the factory have experience?

Supply stability: Is it readily available? What are lead times?

Test data: Is complete material performance data available?

If possible:

Do small trial production with the preferred material

Test key performances (especially high-frequency and thermal)

Evaluate mass production feasibility and cost

If issues arise, return to the previous step for adjustments

Truth: What matches your needs is best. Using high-frequency materials for low-frequency circuits is like using a Ferrari for delivery—overkill and wasteful.

Truth: Performance can vary by up to 30% between different manufacturers and grades of FR-4. For critical applications, always specify brand and type.

Truth: It's also a supply chain decision. A high-performing but unstable material can jeopardize the entire project.

Truth: Changing substrates often requires redesigning the stackup and routing rules—essentially redesigning the board. It's best to choose correctly from the start.

In our Shenzhen factory, we handle circuit boards with various substrates daily. A few observations might help you:

About FR-4 Sub-choices

Even after deciding on FR-4, there are multiple dimensions:

Standard FR-4: Suitable for most consumer products

Mid-Tg FR-4 (Tg ≥ 150°C): For lead-free soldering or moderately high operating temperatures

High-Tg FR-4 (Tg ≥ 170°C): For harsh automotive or industrial environments

Halogen-free FR-4: Meets environmental requirements but requires adjusted processing temperatures

Practical Tips for High-Frequency Materials

For budget-constrained projects needing some high-frequency performance, we often recommend a "mixed-material" strategy: use high-frequency materials only for critical high-speed signal layers, keeping other layers as FR-4. This might increase costs by only 20-30%, not double.

The Best Time to Communicate with Suppliers

The most effective communication happens early in the design phase: "Based on these requirements, what material do you recommend and why?" Good manufacturers can offer more practical advice based on actual production experience than theoretical suggestions.

The Right Way to Test Samples

When you receive sample boards of different materials, don't just test electrical performance. Also test:

Solderability: Solder using your actual production process

Heat resistance: Simulate reflow temperatures to check for bubbling or delamination

Processability: Try drilling and routing to see how easily the material machines

If you're selecting a substrate for a new project but feel uncertain:

List your key requirements (frequency, temperature, environment, etc.)

Prepare 2-3 alternative solutions (different materials or combinations)

Consult at least two manufacturers for technical and cost feedback

Do small-batch comparative testing (if budget allows)

PCB substrate selection is essentially an art of balancing performance, reliability, and cost. There's no perfect material—only the choice most suitable for your specific application.

Understanding the characteristics and applications of various substrates not only helps optimize your current design but also provides clearer decision-making思路 for facing more complex challenges in the future.

After all, a good start is half the battle. And choosing the right substrate is exactly that "good start."

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..